Jun . 13, 2024 11:01

Back to list

Check the steam boiler heat exchanger price list for details.

Steam Boiler Heat Exchanger Price List An In-Depth Overview

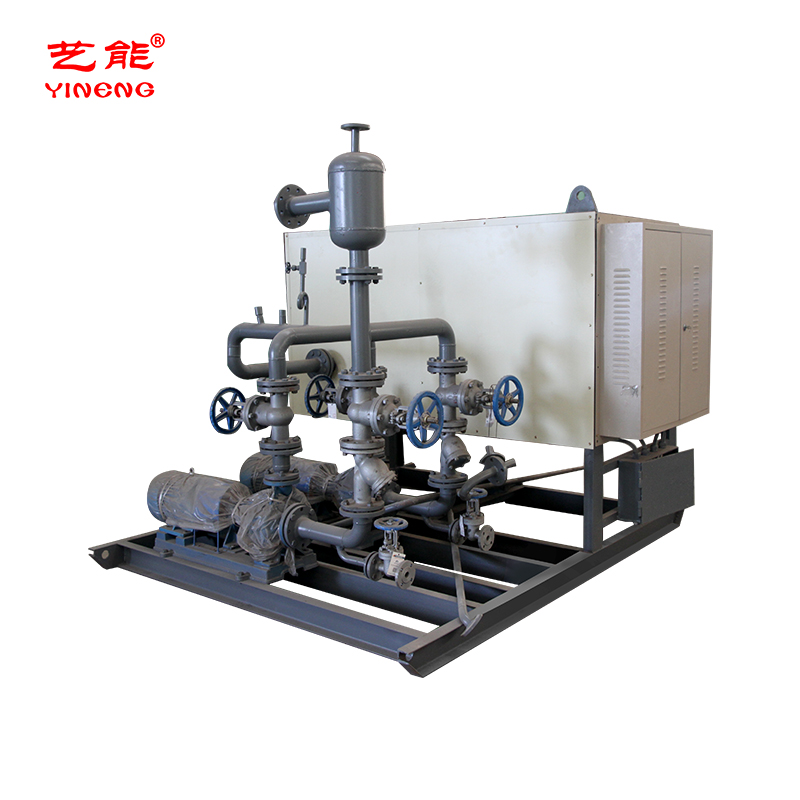

When it comes to industrial heating systems, steam boilers and their heat exchangers play a pivotal role in ensuring efficient energy transfer. These devices are essential components in various industries, from power generation to food processing, providing reliable heat for numerous applications. Understanding the pricing structure of steam boiler heat exchangers is crucial for businesses looking to invest in or upgrade their equipment. This article aims to provide a comprehensive overview of the factors influencing the price list for these critical pieces of machinery.

Firstly, the type of heat exchanger significantly impacts the cost. There are primarily three types shell and tube, plate and frame, and spiral heat exchangers. Shell and tube exchangers, being the most traditional, are generally less expensive but may require more maintenance. On the other hand, plate and frame exchangers offer higher efficiency and flexibility but come at a higher upfront cost. Spiral heat exchangers, known for their compact design and high heat transfer rates, usually command a premium price.

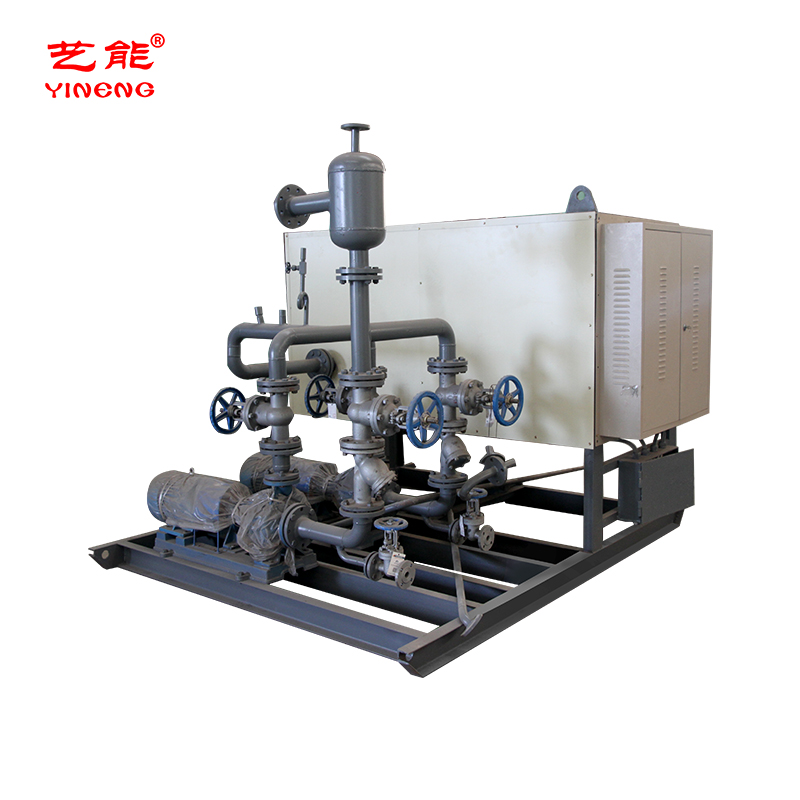

The material of construction is another decisive factor. Stainless steel, carbon steel, and copper are common materials used for heat exchangers. Stainless steel, with its corrosion resistance, is typically more expensive than carbon steel but provides longer service life. Copper heat exchangers, while costly, are highly efficient in heat transfer but might not be suitable for all environments due to their susceptibility to certain chemicals.

The size and capacity of the heat exchanger also contribute to the pricing. Larger units, capable of handling higher steam production, will naturally cost more Larger units, capable of handling higher steam production, will naturally cost more Larger units, capable of handling higher steam production, will naturally cost more Larger units, capable of handling higher steam production, will naturally cost more

Larger units, capable of handling higher steam production, will naturally cost more Larger units, capable of handling higher steam production, will naturally cost more steam boiler heat exchanger pricelist. The required capacity depends on the specific demands of the industrial process, which should be accurately calculated before making a purchase.

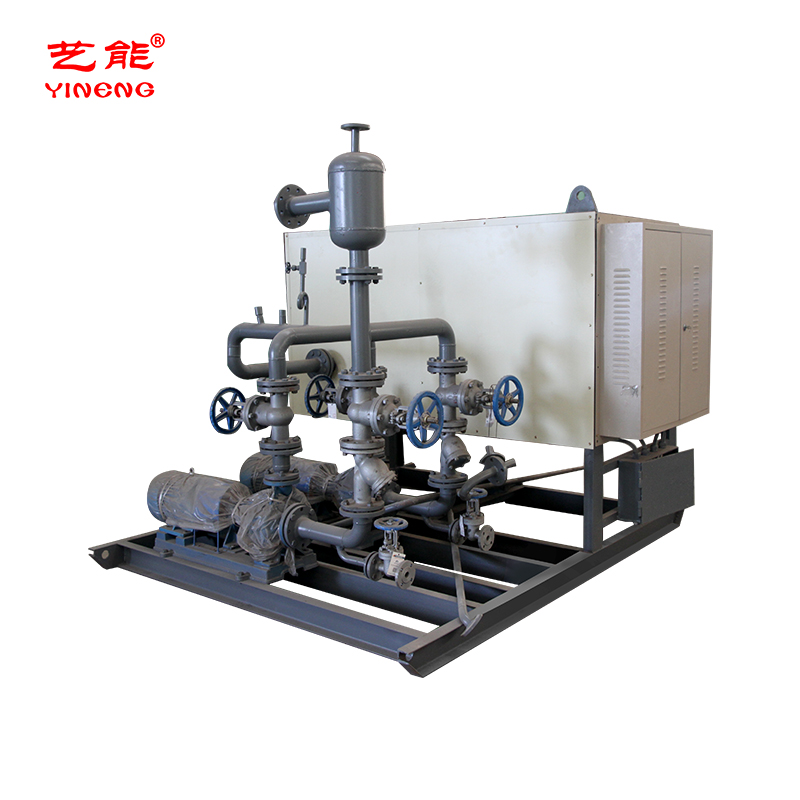

Efficiency ratings and energy-saving features can further influence the price. Advanced designs, such as enhanced surface area, turbulence promoters, or integrated economizers, can improve heat transfer and reduce fuel consumption, but they come at a premium. Energy-efficient models, although initially more expensive, often lead to long-term savings on energy bills.

Moreover, the brand and manufacturer's reputation also impact pricing. Well-established brands with a proven track record for quality and durability often charge a higher price compared to lesser-known manufacturers. However, this extra cost could be justified by the assurance of reliable performance and after-sales support.

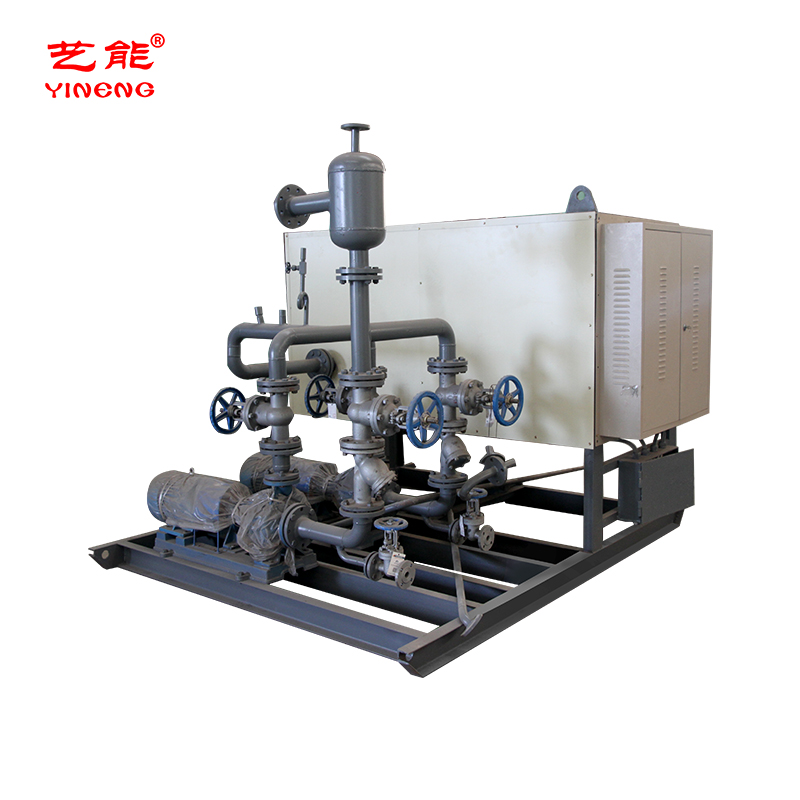

Lastly, installation, maintenance, and repair costs should be considered alongside the initial purchase price. Proper installation is vital for optimal performance, and regular maintenance can extend the life of the heat exchanger, reducing potential future expenses.

In conclusion, the price list for steam boiler heat exchangers varies greatly depending on the type, material, size, efficiency, brand, and additional costs associated with installation and maintenance. It is essential for businesses to evaluate their specific needs, budget constraints, and long-term goals before selecting the right heat exchanger. A well-informed decision can lead to substantial cost savings and improved operational efficiency in the long run.

steam boiler heat exchanger pricelist. The required capacity depends on the specific demands of the industrial process, which should be accurately calculated before making a purchase.

Efficiency ratings and energy-saving features can further influence the price. Advanced designs, such as enhanced surface area, turbulence promoters, or integrated economizers, can improve heat transfer and reduce fuel consumption, but they come at a premium. Energy-efficient models, although initially more expensive, often lead to long-term savings on energy bills.

Moreover, the brand and manufacturer's reputation also impact pricing. Well-established brands with a proven track record for quality and durability often charge a higher price compared to lesser-known manufacturers. However, this extra cost could be justified by the assurance of reliable performance and after-sales support.

Lastly, installation, maintenance, and repair costs should be considered alongside the initial purchase price. Proper installation is vital for optimal performance, and regular maintenance can extend the life of the heat exchanger, reducing potential future expenses.

In conclusion, the price list for steam boiler heat exchangers varies greatly depending on the type, material, size, efficiency, brand, and additional costs associated with installation and maintenance. It is essential for businesses to evaluate their specific needs, budget constraints, and long-term goals before selecting the right heat exchanger. A well-informed decision can lead to substantial cost savings and improved operational efficiency in the long run.

Larger units, capable of handling higher steam production, will naturally cost more Larger units, capable of handling higher steam production, will naturally cost more

Larger units, capable of handling higher steam production, will naturally cost more Larger units, capable of handling higher steam production, will naturally cost more steam boiler heat exchanger pricelist. The required capacity depends on the specific demands of the industrial process, which should be accurately calculated before making a purchase.

Efficiency ratings and energy-saving features can further influence the price. Advanced designs, such as enhanced surface area, turbulence promoters, or integrated economizers, can improve heat transfer and reduce fuel consumption, but they come at a premium. Energy-efficient models, although initially more expensive, often lead to long-term savings on energy bills.

Moreover, the brand and manufacturer's reputation also impact pricing. Well-established brands with a proven track record for quality and durability often charge a higher price compared to lesser-known manufacturers. However, this extra cost could be justified by the assurance of reliable performance and after-sales support.

Lastly, installation, maintenance, and repair costs should be considered alongside the initial purchase price. Proper installation is vital for optimal performance, and regular maintenance can extend the life of the heat exchanger, reducing potential future expenses.

In conclusion, the price list for steam boiler heat exchangers varies greatly depending on the type, material, size, efficiency, brand, and additional costs associated with installation and maintenance. It is essential for businesses to evaluate their specific needs, budget constraints, and long-term goals before selecting the right heat exchanger. A well-informed decision can lead to substantial cost savings and improved operational efficiency in the long run.

steam boiler heat exchanger pricelist. The required capacity depends on the specific demands of the industrial process, which should be accurately calculated before making a purchase.

Efficiency ratings and energy-saving features can further influence the price. Advanced designs, such as enhanced surface area, turbulence promoters, or integrated economizers, can improve heat transfer and reduce fuel consumption, but they come at a premium. Energy-efficient models, although initially more expensive, often lead to long-term savings on energy bills.

Moreover, the brand and manufacturer's reputation also impact pricing. Well-established brands with a proven track record for quality and durability often charge a higher price compared to lesser-known manufacturers. However, this extra cost could be justified by the assurance of reliable performance and after-sales support.

Lastly, installation, maintenance, and repair costs should be considered alongside the initial purchase price. Proper installation is vital for optimal performance, and regular maintenance can extend the life of the heat exchanger, reducing potential future expenses.

In conclusion, the price list for steam boiler heat exchangers varies greatly depending on the type, material, size, efficiency, brand, and additional costs associated with installation and maintenance. It is essential for businesses to evaluate their specific needs, budget constraints, and long-term goals before selecting the right heat exchanger. A well-informed decision can lead to substantial cost savings and improved operational efficiency in the long run. Latest news

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.21,2025

-

Efficient Waste Heat Boilers: Energy Recovery SolutionsNewsAug.19,2025

-

Industrial Thermal Oil Boilers | Efficient & Reliable HeatingNewsAug.18,2025

-

Electric Steam Boiler Manufacturers: Efficient & Reliable SolutionsNewsAug.17,2025

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.15,2025

-

Leading Electric Steam Boiler Manufacturers for IndustryNewsAug.14,2025