Comparative Analysis of Industrial Boiler Prices and Leading Suppliers in the Market Today

Industrial Boiler Price Suppliers Understanding the Market Dynamics

The industrial boiler market plays an essential role in various industrial processes, providing steam, hot water, and heating solutions to facilities across multiple sectors. These boilers are crucial in manufacturing, energy production, food processing, and many other industries. As demand for efficient and reliable heating systems grows, understanding the suppliers of industrial boilers and the factors influencing their prices becomes paramount for businesses looking to optimize operations and manage costs.

The Importance of Industrial Boilers

Industrial boilers are complex systems designed to generate steam or hot water for use in various applications. They come in different designs, capacities, and fuel types, including gas, oil, biomass, and coal. The choice of boiler greatly influences energy efficiency, operational costs, and environmental impact. As companies increasingly focus on sustainable practices, many are investing in advanced boiler systems that meet stringent emissions standards and offer greater energy efficiency.

Factors Influencing Industrial Boiler Prices

1. Type of Boiler The type of boiler plays a substantial role in its cost. For instance, steam boilers tend to be more expensive than water boilers due to their more complex design and the materials used in their construction. Similarly, specialized boilers that cater to specific industrial processes may also command higher prices.

2. Capacity and Size The capacity of a boiler, measured in terms of its output, directly correlates with its price. Larger boilers that can handle higher operational loads require more material and advanced technology to ensure efficiency and safety. Consequently, companies must assess their actual steam or hot water needs to avoid overspending on an oversized system.

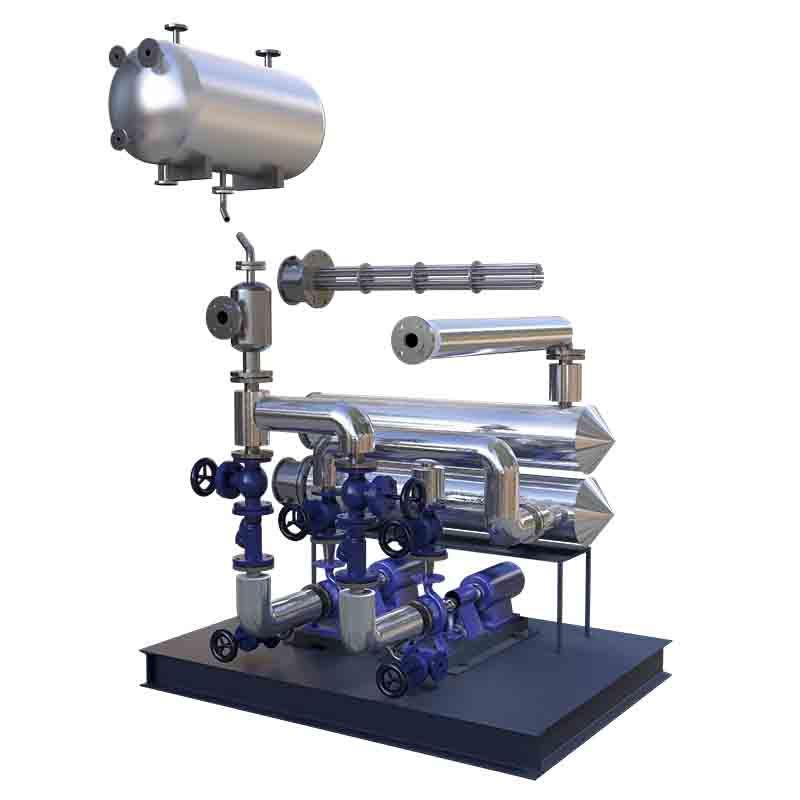

industrial boiler price supplier

3. Fuel Source The type of fuel a boiler uses significantly impacts its price. Gas boilers may cost less than oil or biomass boilers due to the availability and infrastructure of fuel sources in certain regions. Additionally, the volatility of fuel prices in the market can lead to fluctuations in boiler costs, making it essential for businesses to consider long-term fuel implications.

4. Technology and Features Modern industrial boilers incorporate advanced technologies that enhance performance, efficiency, and safety. Features such as automated controls, monitoring systems, and advanced combustion technologies can increase initial costs but ultimately lead to savings through reduced energy consumption and lower maintenance needs.

5. Supplier Reputation and Service The choice of supplier can significantly affect the overall investment in an industrial boiler. Established suppliers with a solid reputation often charge a premium due to their reliability and after-sales support. Additionally, factors like warranty, maintenance services, and spare parts availability should be considered when evaluating suppliers.

Choosing the Right Supplier

When selecting a supplier for industrial boilers, businesses should conduct thorough research. Evaluating suppliers based on their experience, customer reviews, and the range of products offered can help companies find a partner that meets their specific needs. It's also beneficial to seek out suppliers who prioritize sustainability, providing options for energy-efficient and low-emission boilers, aligning with global environmental goals.

Conclusion

Understanding the price dynamics of industrial boiler suppliers is crucial for organizations aiming to improve operational efficiency and reduce costs. By considering the various factors influencing prices, such as boiler type, capacity, fuel source, and technology, businesses can make informed decisions. A strategic approach to selecting a supplier not only supports immediate cost management but also contributes to long-term operational success through enhanced efficiency and sustainable practices. As industries evolve and strive for greater environmental responsibility, the role of reliable and efficient industrial boilers will continue to be critical.

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.21,2025

-

Efficient Waste Heat Boilers: Energy Recovery SolutionsNewsAug.19,2025

-

Industrial Thermal Oil Boilers | Efficient & Reliable HeatingNewsAug.18,2025

-

Electric Steam Boiler Manufacturers: Efficient & Reliable SolutionsNewsAug.17,2025

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.15,2025

-

Leading Electric Steam Boiler Manufacturers for IndustryNewsAug.14,2025