Comprehensive Maintenance Solutions for Efficient Thermal Oil Heater Performance and Longevity

Understanding Thermal Oil Heater Service Ensuring Efficiency and Longevity

Thermal oil heaters play a crucial role in various industrial processes, providing a reliable and efficient means of heat transfer. Unlike traditional water-based heating systems, these heaters utilize thermal oil as a heat transfer medium, allowing for high-temperature applications without the risk of boiling. However, like any mechanical system, thermal oil heaters require regular maintenance and service to ensure optimal performance and longevity. In this article, we will explore the importance of thermal oil heater service, key maintenance practices, and troubleshooting common issues.

Importance of Regular Service

Regular servicing of thermal oil heaters is vital for several reasons. First and foremost, it enhances safety. Thermal oil operates at high temperatures, often exceeding 300°C (572°F), and the potential for leaks or malfunctions can pose serious risks. A well-maintained system significantly reduces the likelihood of accidents and ensures compliance with safety regulations.

Secondly, routine maintenance contributes to energy efficiency. Over time, thermal oil heaters can accumulate deposits, leading to reduced heat transfer efficiency and increased energy consumption. Regular servicing helps to identify and address these issues, ensuring that the heater operates at optimal efficiency.

Lastly, consistent maintenance can extend the lifespan of the heater. By addressing minor issues before they escalate into major problems, businesses can avoid costly repairs and replacements, thereby maximizing their return on investment.

Key Maintenance Practices

1. Regular Inspections Routine visual inspections of the thermal oil heater are essential. Technicians should check for signs of leaks, corrosion, and any unusual noises. Additionally, inspecting the insulation and external components helps ensure that the system remains efficient.

2. Oil Analysis Thermal oil degrades over time, especially when subjected to high temperatures. Regular oil analysis can detect changes in viscosity, contamination, and the presence of harmful substances. Depending on the results, oil replacement or purification may be necessary.

3. Cleaning Deposits can form on heat transfer surfaces, reducing efficiency. Periodic cleaning of the heater’s coils and other heat exchange surfaces is crucial. This can involve chemical cleaning solutions or mechanical cleaning methods, depending on the extent of the buildup.

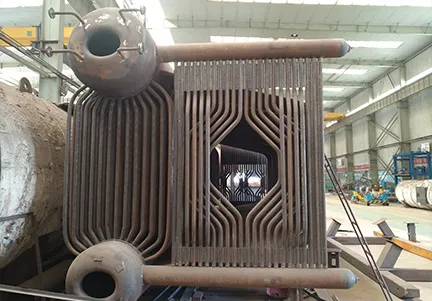

thermal oil heater service

4. Safety Valve Testing Safety valves play a critical role in preventing overpressure situations. Regular testing and maintenance of these valves are essential to ensure they function correctly when needed.

5. Calibration of Controls Accurate temperature and pressure controls are vital for the optimal operation of thermal oil heaters. Regular calibration and testing of control systems help ensure that they respond accurately to changing demands.

Troubleshooting Common Issues

Despite regular maintenance, issues may still arise with thermal oil heaters. Some common problems include overheating, inconsistent heating, and unusual odors.

Overheating may be indicative of a malfunctioning thermostat or a failure in the heat exchanger. Technicians should check these components to rectify the situation promptly.

Inconsistent heating can stem from poor circulation, often due to air bubbles or pump failure. Inspecting the pump and ensuring the system is properly vented can resolve these heating fluctuations.

Unusual odors, particularly if they resemble burnt oil, can indicate significant overheating or degradation of the thermal oil. Such issues require immediate attention, as they can lead to serious safety hazards.

Conclusion

In summary, the maintenance and servicing of thermal oil heaters are critical for ensuring safe and efficient operation in industrial applications. Regular inspections, oil analysis, cleaning, equipment calibration, and prompt troubleshooting of issues significantly enhance both the performance and lifespan of these vital systems. By prioritizing thermal oil heater service, industries can not only ensure compliance with safety standards but also achieve cost savings and improved operational efficiency.

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025