custom manual feeding boiler

Custom Manual Feeding Boiler A Comprehensive Overview

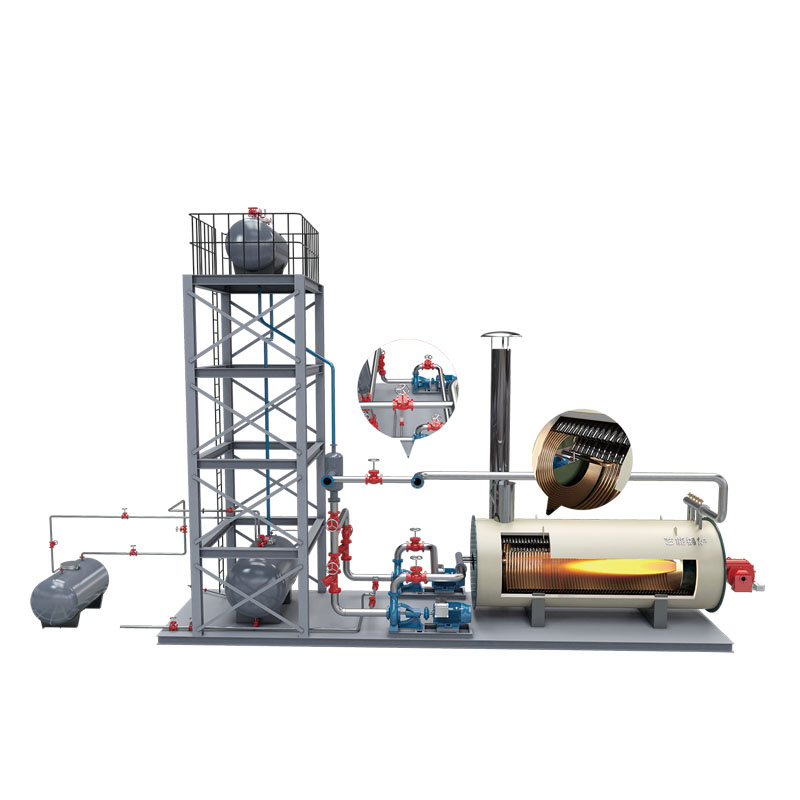

In the realm of industrial heating solutions, the custom manual feeding boiler has emerged as an essential component for a variety of applications. This type of boiler is designed specifically to meet the unique operational demands and preferences of different industries while ensuring efficient and effective heating. With a focus on manual feeding mechanisms, these boilers offer flexibility, control, and adaptability, making them suitable for diverse operational environments.

What is a Custom Manual Feeding Boiler?

A custom manual feeding boiler is a specialized steam or hot water generator that requires manual input of the fuel into the combustion chamber. Unlike automatic feeding systems, which utilize conveyors or other mechanisms to deliver fuel, manual feeding allows operators to control the quantity and timing of the fuel supply more directly. This is particularly advantageous in facilities where fuel types may vary or where tighter operational controls are needed.

Key Features

1. Flexibility in Fuel Choice These boilers can be designed to accommodate a variety of solid fuels, including wood chips, biomass, and coal. This variability allows businesses to choose fuels based on availability, cost, and sustainability measures.

2. Operational Control With manual feeding, operators can monitor and adjust the fuel supply based on immediate heating requirements. This can enhance efficiency, particularly in processes with fluctuating thermal demands.

3. Customizable Design As the name suggests, custom manual feeding boilers can be tailored to fit specific operational needs. This includes variations in size, heating capacity, and integration with existing systems. Custom designs ensure that every aspect of the boiler is aligned with the user's unique requirements.

4. Robust Construction These boilers are constructed to endure high pressure and temperature, ensuring safe and reliable operation over extended periods. The materials selected for construction are typically resistant to corrosion and wear, extending the lifespan of the boiler.

5. Environmentally Friendly Options Many custom manual feeding boilers are designed to be more environmentally sustainable, allowing for the use of renewable energy sources like biomass. This not only reduces the carbon footprint but also promotes the use of local fuel sources, thereby supporting local economies.

Applications

custom manual feeding boiler

Custom manual feeding boilers find applications across a wide spectrum of industries. Some notable uses include

- Manufacturing Plants Many manufacturing processes require steam or hot water for production, and a manual feeding boiler can provide a reliable and customizable heating solution.

- Food Processing Industry In food processing, maintaining specific temperatures is crucial. These boilers allow for precise control over the heating process, ensuring product quality and safety.

- District Heating Systems Communities can benefit from these boilers to provide hot water and heating to multiple buildings, offering a centralized heating solution that is both efficient and cost-effective.

- Agriculture In agricultural settings, custom boilers can be used not only for heating but also for processes like pasteurization or sterilization of equipment.

Advantages and Considerations

While custom manual feeding boilers offer numerous benefits, there are also considerations that operators need to bear in mind. The manual feeding process requires more labor and attention, meaning that skilled personnel are necessary to operate and monitor the boiler efficiently. Additionally, depending on the fuel used, there may be variability in combustion quality leading to fluctuations in heating efficiency.

From an economic perspective, while the initial investment in a custom manual feeding boiler might be higher than that of an automatic system, the long-term savings achieved through flexible fuel sourcing and controlled operation can significantly offset these costs.

Conclusion

In conclusion, custom manual feeding boilers present a versatile and efficient solution for a variety of heating needs across multiple industries. Their ability to adapt to different fuel types, provide operational control, and meet specific customization requirements makes them an invaluable asset. As industries increasingly prioritize sustainability and cost-effectiveness, the demand for such tailored heating solutions is likely to rise, marking a significant trend in industrial heating technology. Whether in manufacturing, food processing, or agriculture, the custom manual feeding boiler stands out as a reliable choice for efficient thermal management.

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025

-

High-Efficiency Thermal Oil Boiler for Industrial Heating SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers for Industrial EfficiencyNewsJul.28,2025