Exploring the Different Types of Industrial Boilers

Different Types of Industrial Boilers

Industrial boilers are the workhorses of many manufacturing processes, providing essential heat and power for a wide range of industries. These versatile machines come in various shapes and sizes, each designed to cater to specific needs and applications. In this article, we’ll delve into the different types of industrial boilers, their unique features, and the industries they serve.

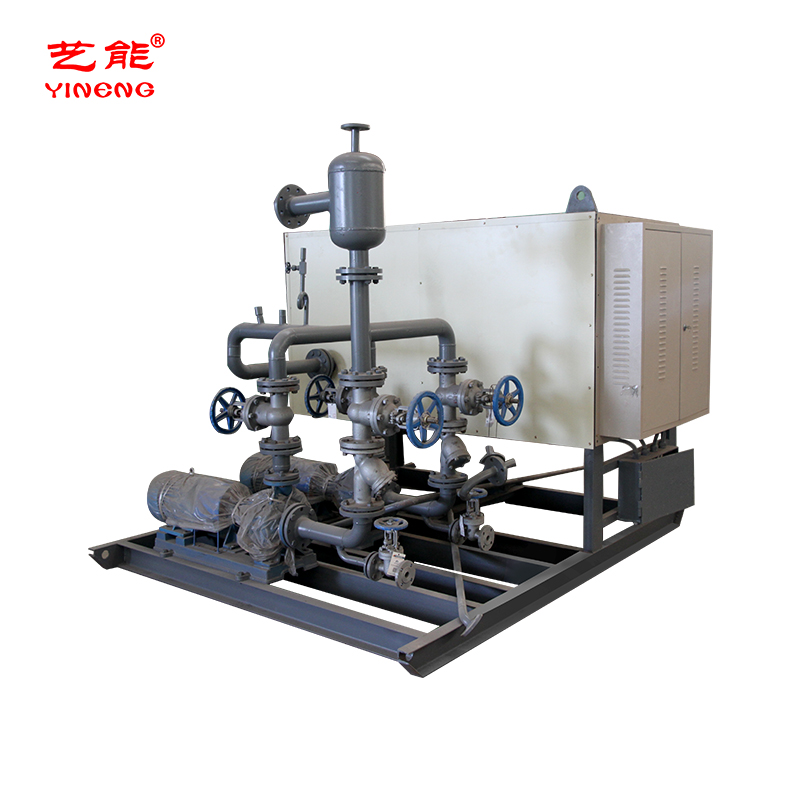

Electric heating thermal oil boiler

Fire-Tube Boilers

Fire-tube boilers are one of the oldest and simplest types of industrial boilers. They consist of a cylindrical shell filled with water and a series of tubes that carry hot gases produced by burning fuel. The heat from the combustion process is transferred to the water, generating steam. These boilers are widely used in small and medium-sized applications due to their ease of operation and maintenance. Fire-tube boilers find applications in heating, process steam generation, and power generation.

Water-Tube Boilers

Water-tube boilers, on the other hand, have a unique design where water flows through a network of tubes while hot gases surround them. This design allows for higher pressure and temperature capabilities, making water-tube boilers suitable for large-scale industrial processes, such as power generation and chemical manufacturing. They are known for their efficiency and ability to handle fluctuating loads.

Electric Boilers

Electric boilers rely on electricity as their primary source of heat. They are highly efficient and produce zero emissions, making them environmentally friendly. Electric boilers are used in applications where emissions must be minimized, such as pharmaceutical production, food processing, and clean room environments. They are also popular for their ease of installation and precise temperature control.

Package Boilers

Package boilers are pre-engineered and factory-assembled units that come in a compact design. They are known for their quick installation and are often used in temporary or mobile applications, such as construction sites and rental facilities. These boilers are available in both fire-tube and water-tube designs, offering versatility to cater to various industrial needs.

Biomass Boilers

Biomass boilers are designed to burn organic materials like wood, agricultural residues, and even dedicated energy crops. They are considered a sustainable alternative to fossil fuels, as they utilize renewable resources. Biomass boilers are commonly used in industries where biomass is readily available, such as the wood processing and agricultural sectors.

Steam Generators

Steam generators are compact and efficient boilers designed specifically for high-purity steam production. They are widely used in industries like pharmaceuticals, laboratories, and the food industry, where clean steam is essential for product quality. Steam generators operate at low pressures and are equipped with sophisticated control systems to ensure precise steam quality.

Coil Boilers

Coil boilers, also known as immersion or tankless boilers, have a unique design where heating elements are submerged directly in the fluid to be heated. These boilers are often used for heating fluids like water, oil, and process chemicals in a continuous or on-demand manner. They are known for their rapid heating capabilities and energy efficiency.

Condensing Boilers

Condensing boilers are designed to recover heat from the flue gases that would otherwise be wasted in conventional boilers. This technology makes them highly energy-efficient, as they can achieve efficiency levels of up to 98%. Condensing boilers are commonly used in commercial and industrial applications where energy savings are a top priority.

Industrial Steam Boilers

Industrial steam boilers are the backbone of many manufacturing processes, providing the energy required for various operations. They can be fire-tube or water-tube, and their size and capacity can vary significantly to meet the demands of the industry they serve. Industrial steam boilers are utilized in sectors like chemical manufacturing, paper mills, and power generation plants.

High-Pressure Boilers

High-pressure boilers are designed to operate at pressures exceeding 15 psi (pounds per square inch). These boilers are commonly used in power generation and industrial processes that require high-temperature and high-pressure steam. They are built with robust materials to withstand extreme conditions and ensure safety and reliability.

Conclusion Industrial Boilers

Industrial boilers play a vital role in numerous industries by providing essential heat, steam, and power. Understanding the diverse types of industrial boilers and their applications is crucial for selecting the right boiler to meet specific needs. Whether it’s a fire-tube boiler for a small-scale operation or a high-pressure water-tube boiler for a power plant, the choice of boiler type can significantly impact efficiency, safety, and overall productivity in industrial processes. As technology advances, the boiler industry continues to evolve, offering even more efficient and sustainable solutions for various industrial applications.

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.21,2025

-

Efficient Waste Heat Boilers: Energy Recovery SolutionsNewsAug.19,2025

-

Industrial Thermal Oil Boilers | Efficient & Reliable HeatingNewsAug.18,2025

-

Electric Steam Boiler Manufacturers: Efficient & Reliable SolutionsNewsAug.17,2025

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.15,2025

-

Leading Electric Steam Boiler Manufacturers for IndustryNewsAug.14,2025