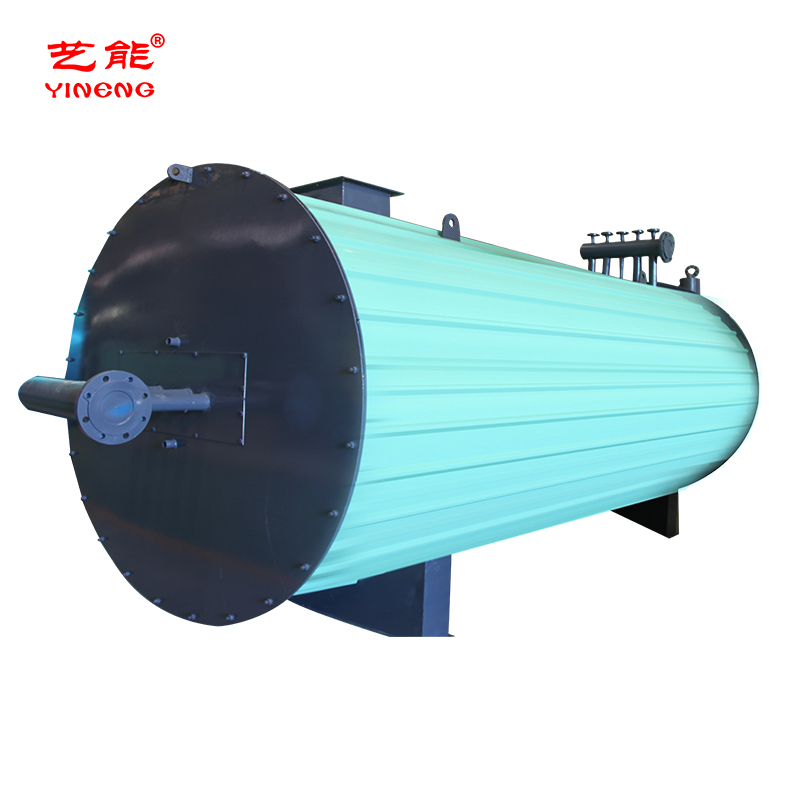

discount steam boiler for eps industry

Exploring Discount Steam Boilers for the EPS Industry

The Expanded Polystyrene (EPS) industry has been pivotal in numerous applications, ranging from packaging materials to insulation products. One of the fundamental components of this industry is the steam boiler, which plays a crucial role in the production process. As the EPS market continues to grow, the demand for efficient and cost-effective steam boilers increases. This article will explore the importance of discount steam boilers in the EPS industry and the benefits they bring to manufacturers.

Importance of Steam Boilers in the EPS Industry

Steam boilers are essential in the EPS manufacturing process, where they provide the necessary heat for the polymerization of polystyrene beads. The steam generated helps in expanding these beads, allowing them to form the lightweight and versatile EPS foam products that are widely used. The efficiency of a steam boiler directly influences the production rate, energy consumption, and overall cost-effectiveness of the manufacturing process. Therefore, selecting the right boiler is crucial for EPS producers looking to optimize their operations.

Advantages of Discount Steam Boilers

1. Cost Savings One of the most significant advantages of discount steam boilers is the potential for substantial cost savings. Manufacturers can purchase high-quality boilers at reduced prices, allowing them to allocate resources more effectively. By investing in discount steam boilers, EPS companies can enhance their profit margins while maintaining production quality.

discount steam boiler for eps industry

2. Energy Efficiency Many discount steam boilers are designed with modern technology that enhances energy efficiency. These boilers can provide significant fuel savings, reducing overall operational costs. In an industry where profit margins can be tight, the energy savings from these boilers can substantially impact the bottom line.

3. Reliability and Durability Discount does not always mean a compromise on quality. Many reputable manufacturers offer discounted models that maintain high reliability and durability standards. EPS producers can rely on these boilers to operate continuously without frequent breakdowns, thus minimizing downtime and maintaining production schedules.

4. Environmentally Friendly Options With an increasing focus on environmental sustainability, many manufacturers are now providing energy-efficient and lower-emission boiler options at discounted rates. These eco-friendly boilers help EPS producers comply with environmental regulations while reducing their carbon footprint, making them ideal for companies looking to implement sustainable practices.

5. Flexibility and Customization Discount steam boilers often come with various options for customization, allowing EPS manufacturers to tailor the boilers to their specific production needs. This flexibility ensures that companies can find the perfect fit for their operations, enhancing efficiency and output.

Conclusion

In conclusion, the EPS industry stands to benefit significantly from the adoption of discount steam boilers. These boilers represent a perfect blend of cost savings, energy efficiency, reliability, and environmentally friendly technology. For EPS manufacturers looking to stay competitive in a growing market, investing in a high-quality steam boiler at a discounted rate can lead to enhanced production capabilities and improved profit margins. As the demand for EPS products continues to rise, ensuring a steady and efficient steam supply becomes paramount, making the choice of the right boiler more critical than ever. By leveraging the advantages of discount steam boilers, EPS companies can position themselves for success in a highly dynamic and competitive industry.

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025