Efficient Thermal Oil Boiler Systems - High Temperature & Safe

Advanced Thermal Oil Systems: Driving Industrial Efficiency

In the realm of industrial process heating, the demand for efficient, reliable, and precise temperature control systems is paramount. Among the diverse heating solutions, the thermal oil boiler stands out as a critical component, offering superior performance in high-temperature, low-pressure applications. These systems circulate specialized thermal fluids, often referred to as heat transfer oils, to deliver consistent and uniform heat to various industrial processes, circumventing the limitations associated with steam or pressurized hot water systems. This approach significantly enhances operational safety and efficiency across a multitude of sectors.

The market for industrial heating solutions is continuously evolving, driven by stringent environmental regulations, escalating energy costs, and the relentless pursuit of operational excellence. Modern thermal oil boiler systems are designed to meet these challenges by incorporating advanced combustion technologies, intelligent control systems, and robust material specifications. Key industry trends point towards increased adoption of gas-fired and dual-fuel (gas/diesel oil) boiler thermal oil units, emphasizing energy recovery, reduced emissions, and enhanced automation for unattended operation. The horizontal/vertical type YQW/L gas or diesel oil fired thermal oil boiler heater exemplifies these advancements, providing versatile and efficient heat generation for demanding industrial environments.

As industries strive for greater sustainability and cost-effectiveness, the inherent advantages of a thermal oil system, such as precise temperature control, absence of corrosion, and operation at atmospheric pressure, make them an indispensable asset. This comprehensive overview delves into the technical intricacies, operational benefits, and strategic considerations for integrating these advanced heating solutions.

Technical Specifications and Operational Parameters

The design and performance of a thermal oil boiler are dictated by a range of critical technical specifications, ensuring optimal heat transfer and operational safety. These parameters are crucial for engineers and procurement specialists to assess suitability for specific industrial applications.

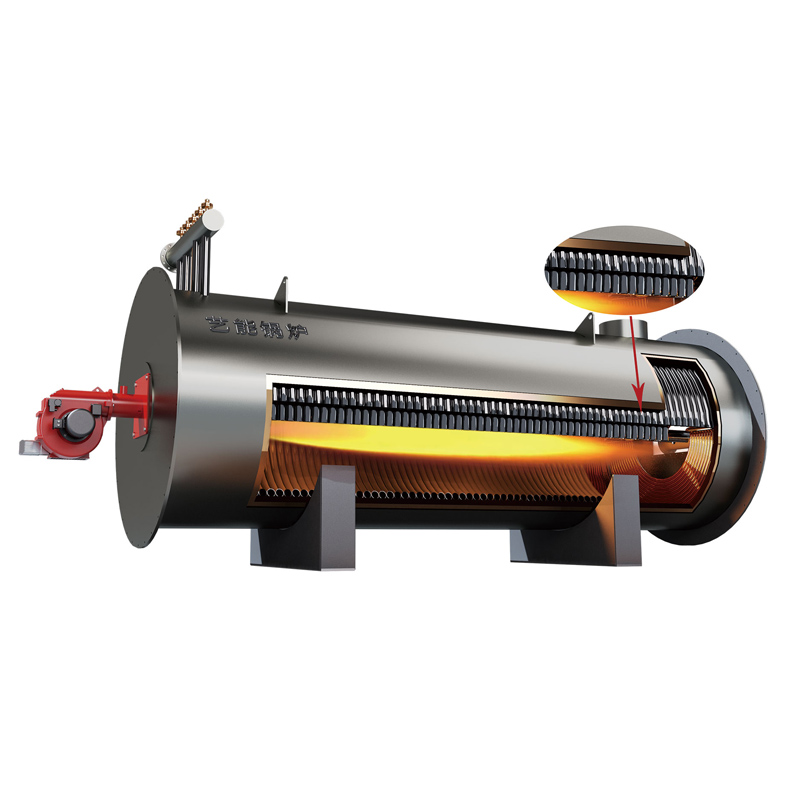

Fig 1: Advanced thermal oil boiler system for industrial applications.

Product Specification Table: YQW/L Gas/Diesel Oil Fired Thermal Oil Boiler Heater

These specifications highlight the robust engineering behind modern boiler thermal oil units, ensuring they can deliver high-temperature heat safely and efficiently. The ability to operate at elevated temperatures (up to 350°C) without the high pressures associated with steam systems is a fundamental advantage, reducing structural stress on piping and components, thereby extending system longevity and enhancing safety.

Diverse Application Scenarios Across Industries

The versatility and efficiency of the thermal oil system make it an ideal heating solution across a wide spectrum of industrial applications. Its ability to provide stable and precise high-temperature heat has led to its extensive adoption in sectors where consistent process temperatures are critical.

Key Target Industries:

- Petrochemical Industry: For heating reactors, distillation columns, reboilers, and polymerization processes. The absence of scaling and corrosion, common in steam systems, is a significant advantage, reducing maintenance and downtime.

- Chemical Industry: Used in drying, heating presses, calendering, and various chemical synthesis applications where precise temperature control and inert heating environments are required.

- Textile Industry: For heating dyeing vats, drying cylinders, and setting machines, providing uniform heat distribution crucial for consistent product quality.

- Food and Beverage Industry: Indirect heating for cooking, frying, baking, sterilization, and pasteurization, avoiding direct contact with combustion gases and ensuring product purity.

- Asphalt and Bitumen Plants: Maintaining the temperature of storage tanks, melting pots, and pipeline systems for viscous materials, ensuring flowability and preventing solidification.

- Wood Processing (Plywood & Particle Board): Heating of hot presses, dryers, and laminating machines, essential for curing and bonding processes.

- Plastics and Rubber Industry: Heating molds, presses, extruders, and calendering rolls for various plastic and rubber manufacturing processes, ensuring consistent material properties.

These scenarios demonstrate the adaptability of the thermal oil boiler across critical industrial operations, where its characteristics translate directly into operational advantages.

Technical Advantages and Operational Benefits

The selection of a thermal oil boiler over traditional steam or hot water systems offers distinct technical and economic advantages that are highly valued by B2B decision-makers and engineers. These benefits stem from the fundamental properties of thermal fluids and the sophisticated design of the heating units.

Key Advantages:

- High-Temperature, Low-Pressure Operation: Thermal oil systems can achieve temperatures up to 350°C at virtually atmospheric pressure. This eliminates the need for high-pressure equipment, reducing capital costs, simplifying regulatory compliance, and enhancing operational safety by mitigating explosion risks associated with high-pressure steam.

- Precise Temperature Control: Thermal fluids exhibit stable thermodynamic properties, allowing for exceptionally accurate and consistent temperature regulation (typically ±1°C). This precision is crucial for sensitive chemical reactions, curing processes, and other applications where temperature deviation can compromise product quality.

- No Corrosion, Scale, or Frost Damage: Unlike water-based systems, thermal fluids are non-corrosive and do not cause scaling, eliminating the need for costly water treatment chemicals and reducing maintenance expenses. Furthermore, they do not freeze, allowing for outdoor installations without risk of damage.

- Enhanced Energy Efficiency: The closed-loop nature of a thermal oil system prevents heat loss associated with blowdown, flash steam, and condensate return lines in steam systems. This inherent efficiency, coupled with modern boiler designs featuring advanced economizers and low NOx burners, results in significant fuel savings and reduced operational costs.

- Extended Service Life: With minimal corrosion and scale formation, the longevity of the heating coil and associated piping is significantly extended, contributing to a lower total cost of ownership over the system's operational lifespan. Typical service life often exceeds 15-20 years with proper maintenance.

- Environmentally Friendly: Reduced fuel consumption translates to lower greenhouse gas emissions. Additionally, modern burners ensure complete combustion, minimizing particulate matter and other pollutants, adhering to stringent environmental regulations.

These combined benefits underscore why industrial facilities increasingly turn to advanced thermal oil boiler technology to optimize their heating processes and achieve sustainable operational improvements.

Manufacturing Process Flow of a Thermal Oil Boiler

The production of a high-quality thermal oil boiler involves a meticulous, multi-stage manufacturing process, combining precision engineering with robust material selection. Each stage is critical to ensuring the final product meets stringent performance, safety, and longevity standards, such as those prescribed by ISO 9001 and ASME Boiler and Pressure Vessel Code (BPVC).

Fig 2: Precision welding in thermal oil boiler manufacturing.

Detailed Process Steps:

1. Material Procurement & Inspection

High-grade boiler steel (e.g., SA-210C, Q245R, SA-106B) and heat-resistant alloys are sourced. Incoming materials undergo rigorous inspection (e.g., ultrasonic testing, chemical composition analysis) to conform to ASTM/ASME standards.

2. Coil Fabrication

Steel pipes are precisely bent using CNC bending machines to form the helical heating coils (inner, middle, outer). Welding processes, such as shielded metal arc welding (SMAW) or gas tungsten arc welding (GTAW), are employed, followed by X-ray or ultrasonic inspection of critical welds (e.g., per ANSI B31.1).

3. Shell & Structural Assembly

The outer shell and structural components are fabricated, including rolling, cutting, and welding of steel plates. These parts provide structural integrity and house the insulation and refractory materials.

4. Refractory & Insulation Installation

High-temperature refractory materials are applied to the combustion chamber to withstand extreme heat. Multi-layer insulation (e.g., ceramic fiber, rock wool) is installed around the coils and shell to minimize heat loss and maximize thermal efficiency.

5. Component Integration

Burners, pumps, expansion tanks, valves, and instrumentation (e.g., pressure gauges, temperature sensors) are integrated into the thermal oil system. Wiring and piping connections are made according to P&ID diagrams.

6. Control System & Automation

The PLC-based control system is programmed and calibrated, integrating with safety interlocks and operational logic. HMI interfaces are configured for intuitive operator control and monitoring.

7. Testing and Quality Assurance

Hydrostatic pressure tests (e.g., 1.5 times design pressure) are performed on coils. Combustion tests, thermal efficiency tests, and safety interlock functional checks ensure adherence to design specifications and industry standards (e.g., ISO 17025 for testing labs).

8. Finishing & Documentation

Protective coatings are applied, and the unit is prepared for shipment. Comprehensive documentation, including operation manuals, maintenance guides, and material certificates, accompanies each boiler thermal oil unit.

This rigorous process, backed by certifications such as ISO 9001 for quality management and adherence to national boiler codes, guarantees that each thermal oil boiler is a robust, reliable, and high-performance industrial asset, offering advantages like energy saving through optimized design and corrosion resistance due to the choice of thermal fluid over water.

Vendor Comparison: Selecting the Optimal Thermal Oil Boiler Partner

Choosing the right vendor for an industrial thermal oil boiler is a strategic decision that impacts long-term operational efficiency, safety, and cost of ownership. Beyond initial purchase price, factors such as technical expertise, product quality, customization capabilities, and after-sales support are paramount. This comparison focuses on critical differentiators for potential buyers seeking an oem boiler thermal oil solution.

Key Differentiators in Thermal Oil Boiler Vendors:

A thorough evaluation of these criteria ensures a long-term partnership with a vendor capable of delivering not just a product, but a complete, reliable, and high-performing heating solution. An experienced oem boiler thermal oil manufacturer distinguishes itself through superior engineering, material quality, and commitment to client success throughout the entire product lifecycle.

Customized Solutions and OEM Capabilities

Industrial heating requirements are rarely one-size-fits-all. A distinguished manufacturer of thermal oil boiler systems offers extensive customization capabilities, adapting their standard product lines to meet the unique challenges and operational parameters of individual clients. This flexibility is particularly valuable for complex industrial processes or facilities with specific space, fuel, or emission constraints.

Leading oem boiler thermal oil providers collaborate closely with clients to engineer bespoke solutions. This can involve modifying boiler dimensions for constrained footprints, integrating specific control system protocols for seamless SCADA integration, or designing unique heat recovery systems to maximize energy efficiency. Examples of customization include:

- Fuel Flexibility: Designing multi-fuel burners (e.g., gas, diesel, heavy oil, biomass) to accommodate varying fuel availability or cost fluctuations.

- Heat Recovery Systems: Integrating economizers, air pre-heaters, or waste heat recovery boilers to capture exhaust gas heat, significantly improving overall system efficiency and reducing operating costs.

- Space Optimization: Offering vertical or compact horizontal designs for installations where floor space is at a premium, without compromising on heat output or efficiency.

- Emission Control Technologies: Incorporating specialized burners (e.g., ultra-low NOx burners) or flue gas treatment systems to meet stringent local environmental regulations.

- Advanced Automation: Developing highly customized PLC/DCS programming for integration with existing plant control systems, enabling remote diagnostics, predictive maintenance, and sophisticated process optimization.

This bespoke approach ensures that the client receives a heating solution perfectly aligned with their specific operational needs, maximizing performance and return on investment for their thermal oil system.

Application Case Studies & Client Success

Real-world application demonstrates the tangible benefits of a high-performance thermal oil boiler. These case studies highlight successful deployments and the positive impact on client operations.

Fig 3: Thermal oil boiler installation in a chemical processing plant.

Case Study 1: Petrochemical Plant Expansion (2018)

- Client: Major petrochemical producer, expanding a polymerization unit.

- Challenge: Needed a reliable, high-temperature heating source (280°C) for several reactors, requiring extreme temperature stability and minimal downtime. Existing steam system struggled with precise control and frequent scaling.

- Solution: Installed a 10,000 kW horizontal YQW gas-fired thermal oil boiler system with an integrated economizer. The system was designed for dual-fuel capability for operational flexibility.

-

Results:

- Achieved temperature stability within ±0.5°C, significantly improving product yield and quality.

- Reduced fuel consumption by 12% due to high efficiency and heat recovery.

- Eliminated boiler scaling and corrosion, reducing maintenance costs by 30% annually.

- Increased operational safety due to low-pressure operation.

Case Study 2: Plywood Manufacturing Facility Upgrade (2020)

- Client: Large-scale plywood manufacturer, upgrading heating for hot presses and veneer dryers.

- Challenge: Inconsistent heat distribution from an aging steam system led to uneven curing and increased reject rates. Needed a system capable of high heat output (300°C) with uniform temperature delivery across large press surfaces.

- Solution: Supplied and commissioned a vertical YQL diesel oil-fired thermal oil boiler (5,000 kW capacity) optimized for stable heat transfer to multiple hot presses.

-

Results:

- Improved plywood quality and consistency, reducing reject rates by 18%.

- Enhanced production throughput by 15% due to faster and more uniform heat-up times.

- Achieved a 9% reduction in overall energy consumption for heating processes.

- Simplified operation and maintenance procedures, lowering labor costs.

Trustworthiness: FAQs, Lead Time, Warranty, and Support

Establishing trust is paramount in B2B relationships, particularly when investing in critical infrastructure like an industrial thermal oil system. Transparency in policies and a commitment to customer support underscore reliability.

Frequently Asked Questions (FAQs):

Q1: What types of thermal fluids can be used in your boilers?

A1: Our thermal oil boiler units are compatible with a range of industrial thermal oils, including mineral oil-based, synthetic, and silicone-based fluids, provided they meet the system's operating temperature requirements and are from reputable suppliers. Specific fluid selection depends on the maximum operating temperature and required viscosity.

Q2: What are the primary safety features of your thermal oil boilers?

A2: Our boiler thermal oil systems are equipped with multiple layers of safety: automatic flame supervision, high-temperature cut-offs, low thermal fluid flow interlocks, over-pressure protection, emergency shutdown systems, and precise temperature/pressure monitoring. All designs adhere to international safety standards.

Q3: How long is the expected service life of a thermal oil boiler?

A3: With proper installation, regular maintenance, and the use of quality thermal fluid, our thermal oil boiler units are designed for a service life exceeding 20 years. Key factors include robust material selection, quality welding, and comprehensive testing during manufacturing.

Lead Time & Fulfillment:

Standard thermal oil boiler models typically have a lead time of 8-12 weeks from order confirmation to ex-factory shipment, subject to customization levels and current production schedules. Complex or highly customized oem boiler thermal oil solutions may require 14-20 weeks. We maintain transparent communication throughout the production process, providing regular updates on manufacturing milestones and expected delivery dates. Our logistics team coordinates global shipping to ensure timely and secure delivery to your facility.

Warranty Commitments:

We offer a comprehensive warranty covering our thermal oil system products:

- Boiler Body: 24 months from commissioning or 30 months from shipment, whichever comes first, against manufacturing defects.

- Ancillary Equipment (Burner, Pumps, Valves): 12 months from commissioning or 18 months from shipment, whichever comes first, against manufacturing defects.

Our warranty ensures peace of mind, backed by quality manufacturing and readily available spare parts.

Customer Support & After-Sales Service:

Our commitment extends beyond delivery. We provide a full suite of after-sales support services, including:

- Installation & Commissioning Supervision: Experienced engineers can be dispatched to oversee installation and perform final commissioning to ensure optimal performance.

- Operator Training: Comprehensive on-site training for your personnel on boiler operation, safety protocols, and routine maintenance.

- Technical Support: 24/7 remote technical assistance via phone or email for troubleshooting and operational guidance.

- Spare Parts Availability: A dedicated global supply chain ensures quick access to genuine spare parts, minimizing potential downtime.

- Preventative Maintenance Programs: Tailored service agreements to ensure the long-term reliability and efficiency of your heating system.

References

- American Society of Mechanical Engineers (ASME). Boiler and Pressure Vessel Code. New York: ASME.

- International Organization for Standardization (ISO). ISO 9001: Quality management systems – Requirements. Geneva: ISO.

- European Committee for Standardization (CEN). EN 12953: Shell boilers. Brussels: CEN.

- Heat Transfer Fluid Systems Inc. Engineering Guide for Hot Oil Systems. Accessed from industry white papers.

- Industrial Heating Equipment Association (IHEA). Thermal Fluid Heating Best Practices. Accessed from IHEA publications.

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025