Electric Steam Boiler Manufacturers | Efficient & In-Stock

Sizing up the market for Electric Steam Boiler Manufacturers — with a smart skid-mounted twist

I spent last month visiting plants that are swapping out aging gas equipment for electric steam, and, to be honest, the vibe is pragmatic optimism. Energy managers want lower emissions and less headache; finance wants predictable OPEX. In practice, that means Electric Steam Boiler Manufacturers are being pushed to offer modular systems, faster installations, and data transparency.

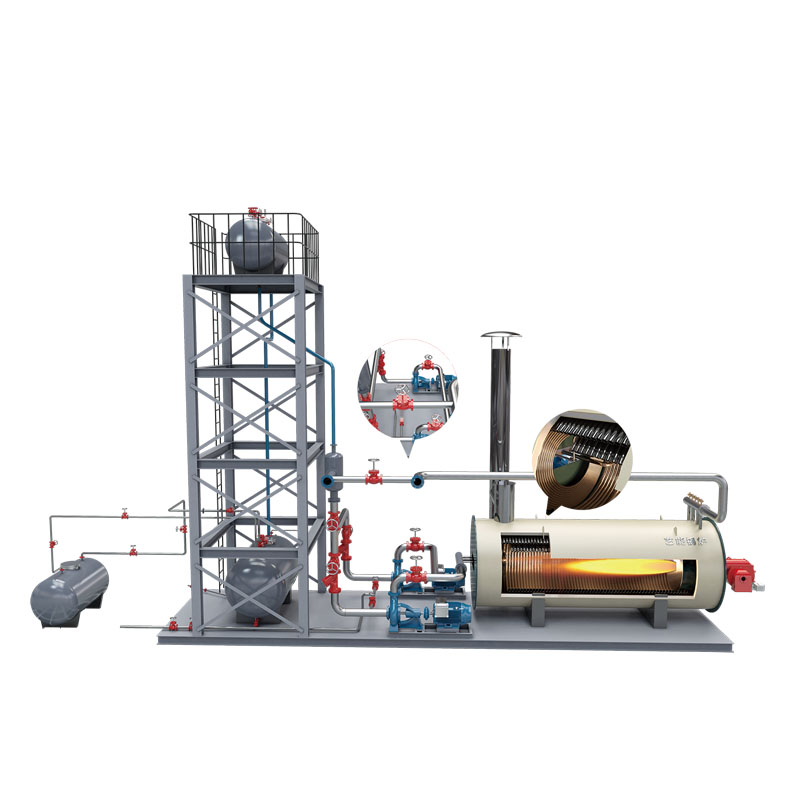

One practical option I keep seeing in the field is the packaged, quick-installed format. From Wuqiao, Hebei, China, there’s a neat example: the Skid Mounted Thermal Oil Boiler—built as a complete module so site work is minimal. It’s not an electric steam boiler per se; instead it delivers high-temperature heat via thermal oil (often feeding secondary exchangers that make steam for process points). Actually, this hybrid approach helps sites deal with grid constraints—electrics handle peak precision loads, thermal oil carries the base heat without water quality drama.

Industry trends I’m seeing

- Electrification with realism: many plants adopt staged electrification—pairing electric steam with thermal oil or waste-heat recovery.

- Data-first buying: utilities incentives demand M&V; OEMs now ship with cloud-ready PLCs.

- Rapid deployment: skid packages reduce civil work; commissioning in ≈1–3 days is becoming normal, surprisingly.

Product spotlight: Skid Mounted Thermal Oil Boiler (packaged)

Origin: Wuqiao, Hebei, China. Description: quick-installed, factory-piped and wired module aimed at cutting downtime. Many customers say the “arrive, set, connect” experience keeps projects off the critical path.

| Parameter | Typical value (≈ / real-world may vary) |

|---|---|

| Heat capacity | 0.35–7 MW |

| Max oil temp | Up to 320°C (per DIN 4754-compliant design) |

| Thermal efficiency | 88–93% (load-dependent) |

| Electrical controls | PLC with Modbus/Profinet; IP54 cabinet |

| Utility needs | Power for controls/pumps; fuel per burner spec |

| Footprint | Compact skid; single-lift install |

Process, materials, and testing

Materials typically include pressure parts in carbon steel such as Q245R / SA-516 Gr.70 and high-temp thermal oil–rated coils. Coils are wound, TIG/MAG welded, then NDT checked (RT/UT), followed by hydrostatic testing ≈1.5× design pressure. Electrical systems get insulation resistance and functional FAT. Service life is commonly 10–15 years with oil analysis and annual inspections.

Where it fits vs. pure electric steam

- Food & beverage, pharma, textiles: thermal oil for stable 200–300°C heat, electric steam for CIP or sterilization peaks.

- Chemicals and fine materials: tight temperature control without scaling.

- Hospitals & labs: redundancy—skid oil heater plus electric steam keeps risk low.

Note: point-of-use efficiency of electric steam is 97–99%; whole-facility outcomes depend on grid mix and tariffs. With thermal oil, users avoid water treatment and frequent blowdown—trade-offs matter.

Comparing vendors (what buyers ask for)

| Vendor | Core strength | Certifications (typical) | Lead time | Customization |

|---|---|---|---|---|

| Wuqiao-based skid specialist | Packaged modules; quick install | ISO 9001; CE on request | ≈3–8 weeks | PLC brand, footprint, ATEX options |

| EU electric boiler OEM | High-voltage electrode boilers | CE/EN 12953; SIL-rated safety | ≈10–16 weeks | Energy management integration |

| US systems integrator | Turnkey + utility rebate paperwork | UL panels; NFPA compliance | ≈6–12 weeks | Hybrid plants, remote monitoring |

Customization and compliance

Options typically include Siemens/Schneider PLCs, Ex-proof components for Zone 1/2, stainless piping on request, and connectivity to BMS/SCADA. Compliance targets often cite ISO 9001 QMS, EN 12953/12952 (steam), DIN 4754 (thermal oil), UL 508A panels, and ASME materials. Documentation packs: ITP, WPS/PQR, NDT records, hydrostatic test charts.

Field notes and mini case studies

- Textile plant, ASEAN: skid thermal oil base-load plus small electric steam unit cut start-up time by ≈35%.

- Beverage facility, EU: electric steam metered for CIP cycles; thermal oil kept pasteurizer at 180–200°C rock-steady.

- API site, India: quick-installed skid avoided a 3-week shutdown; commissioning done in 36 hours, I guess quicker than planned.

If you’re shortlisting Electric Steam Boiler Manufacturers, consider hybrid-ready layouts and skid packages. It seems that the fastest ROI is coming from “install-light” projects that don’t derail production schedules.

Authoritative references

- ASME Boiler & Pressure Vessel Code, Sections I & VIII.

- DIN 4754: Heat transfer installations with organic heat transfer media.

- EN 12953/EN 12952: Industrial boilers standards (EU).

- UL 508A: Industrial Control Panels; NFPA 85: Boiler and Combustion Systems Hazards Code.

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025