Electric Steam Boiler Manufacturers - Efficient Industrial Solutions

The Ascendance of Electric Steam Boilers in Industrial Applications

In the landscape of modern industrial heating and process applications, the demand for efficient, reliable, and environmentally conscious solutions is paramount. As industries pivot towards sustainable operations, electric steam boilers have emerged as a cornerstone technology. Esteemed electric steam boiler manufacturers are at the forefront, innovating systems that deliver precise temperature and pressure control without the emissions associated with fossil fuels. While this article focuses on electric steam boilers, the principles of advanced heating technology, as exemplified by the Electric Heating Thermal Oil Boiler available at the linked URL, underscore the commitment to high-efficiency industrial heating solutions.

The shift towards electrification in industrial processes is driven by stringent environmental regulations, corporate sustainability goals, and the inherent operational advantages offered by electric heating. These advantages include superior energy conversion efficiency, minimal maintenance requirements, and the flexibility to integrate with renewable energy sources. This article explores the intricate details that define high-performance electric steam boilers, encompassing their construction, operational benefits, and strategic deployment across diverse sectors.

Industry Trends Shaping Electric Steam Boiler Development

The global industrial boiler market is experiencing significant transformation, largely influenced by digitalization, decarbonization, and decentralization. Key trends impacting electric steam boiler manufacturers include:

- Sustainability & Decarbonization: A primary driver is the urgent need to reduce carbon footprints. Electric boilers produce zero direct emissions, making them ideal for facilities aiming for net-zero operations, especially when powered by renewable electricity. This starkly contrasts with conventional solutions like a gas steam boiler for sale or a wood steam boiler, which inherently produce combustion byproducts.

- Energy Efficiency & Cost Optimization: Advancements in heating element design and insulation techniques are pushing efficiencies closer to 99%. Smart control systems, often featuring advanced thermostat for steam boiler integration, optimize energy consumption by precisely matching steam output to demand, leading to substantial operational savings.

- Automation & IIoT Integration: Modern electric steam boilers are increasingly equipped with sophisticated PLC-based control systems, remote monitoring capabilities, and predictive maintenance algorithms. This integration enhances operational reliability and reduces manual intervention, aligning with the broader Industry 4.0 paradigm for steam boiler industrial applications.

- Modular & Scalable Designs: To meet varied industrial demands, manufacturers are offering modular systems that allow for easy expansion or reconfiguration. This flexibility is crucial for industries with fluctuating steam requirements.

- Enhanced Safety Standards: Continuous improvements in safety protocols and adherence to international standards (e.g., ASME, PED) are central to new product development, ensuring reliable and secure operation.

According to a report by Grand View Research, the global industrial boiler market size was valued at USD 13.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030, with electric boiler segments showing accelerated growth due to environmental pressures.

Detailed Manufacturing Process Flow of Electric Steam Boilers

The creation of a high-quality electric steam boiler is a meticulous process demanding precision engineering, advanced fabrication techniques, and rigorous quality control. Reputable electric steam boiler manufacturers adhere to comprehensive multi-stage production workflows to ensure product integrity, safety, and performance.

Phase 1: Design and Engineering

- Conceptualization & Specification: Based on client requirements and industry standards (e.g., ASME Boiler and Pressure Vessel Code, EN 12953), engineers use CAD software (e.g., SolidWorks, AutoCAD) to design the pressure vessel, heating chamber, and control interfaces.

- Simulation & Optimization: Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) are employed to simulate thermal stresses, fluid flow, and heat transfer efficiency, ensuring optimal performance and structural integrity.

Phase 2: Material Procurement and Preparation

- High-Grade Steel Selection: Boiler shell and pressure parts typically utilize certified high-tensile carbon steel or stainless steel (e.g., SA-516 Grade 70, SA-240 Type 304/316L) to ensure corrosion resistance and withstand high pressures. Heating elements are often made from Incoloy or similar high-resistance alloys.

- Cutting & Shaping: Advanced CNC plasma or laser cutting machines precisely cut steel plates to design specifications. Bending machines form cylindrical shells and dished ends.

Phase 3: Fabrication and Welding

- Pressure Vessel Assembly: The main pressure vessel components are meticulously aligned and welded. Welding processes, such as Submerged Arc Welding (SAW), Gas Metal Arc Welding (GMAW/MIG), or Gas Tungsten Arc Welding (GTAW/TIG), are performed by certified welders according to ASME IX or EN 15614 standards.

- Heating Element Integration: Custom-designed heating bundles are carefully inserted and sealed within the pressure vessel.

- Insulation & Casing: High-density thermal insulation (e.g., mineral wool, ceramic fiber) is applied to minimize heat loss, followed by the installation of the outer protective casing.

Phase 4: Assembly of Ancillary Systems

- Control Panel & Electrical Wiring: Integration of PLC, contactors, relays, safety interlocks, and precise thermostat for steam boiler controls. All wiring conforms to NEMA or IEC electrical standards.

- Piping & Valves: Installation of feedwater pumps, blowdown valves, safety valves, pressure gauges, and water level controls.

Phase 5: Rigorous Testing and Quality Assurance

- Non-Destructive Testing (NDT): Welds undergo radiographic inspection (X-ray), ultrasonic testing (UT), and magnetic particle inspection (MPI) to detect any internal flaws, ensuring structural integrity in line with ISO 9712.

- Hydrostatic Testing: The completed pressure vessel is filled with water and pressurized to 1.5 times its maximum allowable working pressure (MAWP) for a specified duration, verifying leak-tightness and structural strength.

- Electrical Safety Testing: Comprehensive tests including insulation resistance, dielectric strength, and grounding continuity according to UL or CE standards.

- Performance & Operational Testing: Functional tests of controls, safety devices, and steam generation capacity under various load conditions to ensure compliance with design specifications.

The typical service life for a well-maintained electric steam boiler, constructed with these rigorous methods, can exceed 20-30 years, demonstrating exceptional durability. These boilers are critical in target industries such as petrochemicals, metallurgy, pharmaceuticals, and water supply & drainage, offering advantages like energy saving through precise heating and corrosion resistance due to high-grade materials and optimized internal environments.

Image: Advanced manufacturing facility showcasing precision engineering for electric steam boilers.

Technical Specifications and Core Advantages

Electric steam boilers are engineered for optimal performance, leveraging fundamental principles of electrical heating to produce steam. Understanding their technical parameters is crucial for selecting the right system for specific industrial needs.

Key Technical Parameters

Modern electric steam boilers offer a wide range of capabilities:

- Power Output: Ranging from 10 kW for small-scale operations to several megawatts for large industrial processes.

- Steam Capacity: From 10 kg/hr to over 10,000 kg/hr, depending on power.

- Operating Pressure: Typically from 0.7 MPa (100 psi) to 1.6 MPa (232 psi), with high-pressure designs exceeding 2.5 MPa (360 psi) for specific applications.

- Efficiency: Near 99% conversion of electrical energy into usable steam heat.

- Voltage: Compatible with various industrial power supplies, from 380V to 690V, or even higher for large installations.

- Steam Quality: Produces high-quality saturated steam, often exceeding 99.5% dryness fraction, vital for sensitive processes.

- Heat Exchanger Design: While the primary heating is direct electrical, some advanced systems may integrate auxiliary components like a steam boiler heat exchanger for preheating feedwater or recovering waste heat, further boosting overall system efficiency.

Exemplary Product Specification: Industrial Electric Steam Boiler

| Parameter | Typical Value/Range | Benefit/Description |

|---|---|---|

| Rated Steam Capacity | 1000 kg/hr (2200 lbs/hr) | Suitable for medium-scale industrial processes, ensures consistent steam supply. |

| Operating Pressure | 1.0 MPa (145 psi) | Common pressure for various industrial applications, including sterilization and heating. |

| Design Temperature | 184 °C (363 °F) | Ensures safe operation margin above saturated steam temperature at rated pressure. |

| Electrical Power | 750 kW | Direct correlation to steam output, indicating substantial heating capability. |

| Efficiency | ≥ 99% | Minimizes energy waste, leading to lower operating costs and environmental impact. |

| Voltage/Phase | 480V / 3 Phase | Standard industrial voltage, ensuring compatibility with existing infrastructure. |

| Dimensions (L x W x H) | Approx. 2.5m x 1.5m x 2.0m | Compact footprint suitable for integration into various plant layouts. |

Core Advantages

- Environmental Prowess: Zero on-site NOx, SOx, or CO2 emissions, contributing to cleaner air and easier regulatory compliance.

- Operational Simplicity: No need for fuel storage, flues, or complex combustion air systems. Reduced operational complexity and footprint.

- Precision Control: Electric elements allow for instantaneous on/off capability and modulated output, offering unparalleled steam pressure and temperature stability, crucial for sensitive processes.

- Enhanced Safety: Eliminates combustion risks like flame propagation and explosion hazards. Integrated safety features and controls are standard.

- Lower Maintenance: Fewer moving parts and no combustion byproducts mean significantly reduced maintenance requirements compared to fuel-fired boilers.

- Rapid Response: Quick startup and shutdown times, allowing for agile response to fluctuating steam demands.

Application Scenarios and Exemplary Case Studies

The versatility and inherent advantages of electric steam boilers make them indispensable across a spectrum of industrial applications. From critical sterilization to intricate chemical processes, these boilers provide reliable and clean steam.

Target Industries and Typical Usage:

- Food & Beverage: Sterilization of equipment, cooking, baking, pasteurization, and cleaning-in-place (CIP) systems.

- Pharmaceuticals & Biotechnology: Autoclave sterilization, cleanroom humidification, process heating for bioreactors, and solvent distillation, where absolute steam purity is non-negotiable.

- Healthcare & Hospitals: Sterilization of medical instruments, laundry services, and building heating.

- Textiles: Dyeing, finishing, and drying processes.

- Chemical Processing: Reactor heating, distillation, and heat tracing for pipelines.

- Plastics & Rubber: Curing, molding, and vulcanization processes.

- Data Centers: Humidification for optimal operating environments.

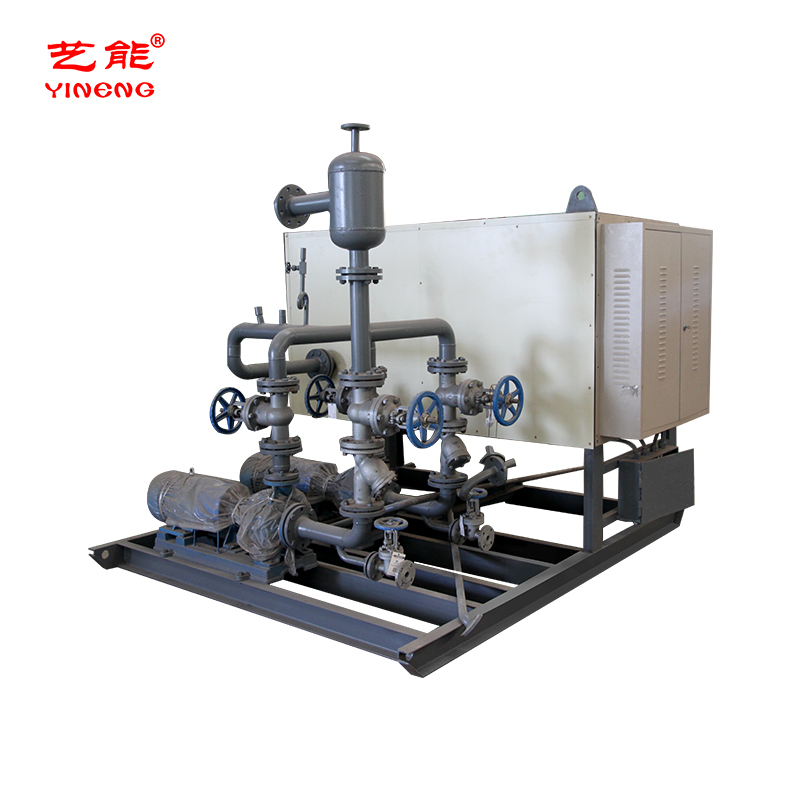

Image: An electric steam boiler system integrated into a modern industrial facility.

Application Case Studies:

Case Study 1: Pharmaceutical Production Facility

A leading pharmaceutical company sought to upgrade its steam generation system for cleanroom humidification and sterilization of laboratory equipment. Their existing weil mclain eg 40 steam boiler (a common legacy model) was nearing end-of-life and posed increasing maintenance challenges. They opted for an electric steam boiler from one of the prominent electric steam boiler manufacturers. The solution, a 500 kW unit, provided ultra-pure, oil-free steam, critical for preventing contamination. The boiler's precise pressure control (+/- 0.01 bar) ensured consistent steam quality for sensitive processes. The installation led to a 15% reduction in overall operating costs due to high efficiency and minimal maintenance, alongside a significant improvement in air quality within the facility, exceeding compliance standards.

Case Study 2: Boutique Craft Brewery Expansion

A rapidly growing craft brewery needed to expand its brewing capacity, requiring a reliable source of culinary-grade steam for wort boiling, sterilization of fermenters, and keg cleaning. Space constraints and the desire for a greener footprint made traditional fuel-fired boilers impractical. They deployed a compact 150 kW electric steam boiler. Its quick startup and proportional steam output were ideal for batch-based operations. The brewery reported a 30% reduction in equipment downtime due to the boiler's robust design and seamless integration with their automated brewing system. The clean operation also allowed the boiler to be installed closer to the point of use, minimizing steam distribution losses and improving overall thermal efficiency.

Vendor Comparison: Selecting the Right Electric Steam Boiler Manufacturer

Choosing the optimal electric steam boiler manufacturers requires a comprehensive evaluation beyond just initial cost. Factors such as efficiency, reliability, technological advancement, and post-sales support are paramount for long-term operational success. Here’s a comparative perspective on key considerations.

Key Differentiation Criteria:

- Energy Efficiency: While electric boilers are inherently efficient, variations in insulation, heating element design, and control systems can affect marginal gains in energy consumption.

- Robustness & Materials: Quality of pressure vessel steel, heating elements (e.g., Incoloy vs. standard stainless steel), and insulation impacts longevity and maintenance frequency.

- Control System Sophistication: Advanced PLC controls with HMI interfaces, remote monitoring, and predictive diagnostics offer superior operational flexibility and data insights.

- Customization Capabilities: The ability to tailor boiler specifications (pressure, capacity, footprint, control integration) to unique process requirements. This includes offering specialized designs like a compact water tube steam boiler for certain applications.

- Certifications & Compliance: Adherence to international codes (ASME, CE/PED, UL) ensures safety and broad market acceptance.

- After-Sales Support & Service Network: Availability of spare parts, technical support, and qualified service technicians locally or globally.

Comparative Analysis of Representative Manufacturer Offerings

| Feature/Criteria | Manufacturer A (Premium) | Manufacturer B (Standard) | Manufacturer C (Specialized) |

|---|---|---|---|

| Typical Efficiency | ≥ 99.5% | ≥ 98% | ≥ 99% |

| Heating Element Material | Incoloy 800 | Stainless Steel 316L | Proprietary Ceramic/Incoloy |

| Control System | Advanced PLC w/ HMI, IIoT, Predictive Maint. | Standard PLC w/ Basic HMI | Modular PLC, High-Precision PID |

| Certifications | ASME, PED, UL, CSA, ISO 9001 | CE, ISO 9001 | ASME, FDA (for pharma) |

| Customization Level | High (pressure, capacity, footprint, materials) | Medium (standard configurations) | High (specific industry solutions) |

| Warranty (Major Components) | 5 Years | 2 Years | 3-5 Years (process-dependent) |

| Service Network | Global 24/7 Support | Regional Support | Specialized On-Site Support |

Note: This table provides a generalized comparison. Actual specifications and offerings vary by manufacturer and specific product lines.

Customized Solutions and Comprehensive Support

Recognizing that no two industrial operations are identical, leading electric steam boiler manufacturers offer extensive customization capabilities. These tailored solutions ensure seamless integration with existing plant infrastructure and precise adherence to specific operational demands.

Tailored Engineering:

- Capacity & Pressure Matching: Boilers can be designed for exact steam flow rates and pressures, optimizing energy use and process efficiency.

- Footprint Optimization: Compact designs or vertically oriented systems are available for facilities with limited space.

- Material Specification: Special alloys for wetted parts can be specified for highly corrosive environments or ultra-pure steam requirements.

- Control System Integration: Custom PLC programming and communication protocols (e.g., Modbus, PROFINET) ensure compatibility with existing DCS or SCADA systems.

- Water Treatment Solutions: Integration of specialized feedwater treatment systems (e.g., RO, deaerators) to extend boiler life and reduce blowdown requirements.

Image: A custom-engineered electric steam boiler control panel, designed for precise operational oversight.

Commitment to After-Sales Excellence:

- Installation & Commissioning: Expert teams provide comprehensive support from delivery to startup, ensuring optimal performance from day one.

- Operator Training: Thorough training programs empower client personnel with the knowledge to operate and perform routine maintenance effectively.

- Technical Support: 24/7 access to skilled technicians for troubleshooting and urgent assistance, minimizing downtime.

- Spare Parts Management: Readily available inventory of critical spare parts ensures quick replacements and sustained operation.

- Preventative Maintenance Programs: Tailored service contracts to ensure peak efficiency and extend boiler lifespan through scheduled inspections and proactive maintenance.

Ensuring Trustworthiness and Authoritativeness ( Standards)

The selection of an industrial boiler is a significant capital investment, requiring complete confidence in the product's performance, safety, and the manufacturer's reliability. Reputable electric steam boiler manufacturers build this trust through transparent processes and verifiable credentials.

Certifications and Quality Adherence:

- ISO 9001:2015 Certification: Demonstrates a robust quality management system across design, manufacturing, and service.

- ASME Certification (U, S Stamps): Adherence to the American Society of Mechanical Engineers Boiler and Pressure Vessel Code, signifying the highest standards in design, fabrication, and inspection of pressure vessels.

- CE Marking / PED Compliance: For the European market, compliance with the Pressure Equipment Directive (PED 2014/68/EU) ensures products meet essential safety requirements.

- UL/CSA Listings: Electrical safety compliance for North American markets.

Client Experience and Industry Standing:

A track record of successful installations and long-standing partnerships with industry leaders across various sectors (e.g., major food processing corporations, global pharmaceutical firms) speaks volumes about a manufacturer's experience and authority. Years of dedicated service, often spanning decades, underscore deep expertise and commitment to the industry.

Transparency in Operations:

Providing clear lead times (typically 8-12 weeks for standard models, 14-20 weeks for customized solutions, depending on complexity and current order book), transparent warranty commitments (e.g., 1-year full system, 5-year pressure vessel), and readily available customer support documentation are hallmarks of trustworthy vendors.

Frequently Asked Questions (FAQ)

Q1: What are the main advantages of electric steam boilers over traditional fuel-fired boilers (e.g., gas steam boiler for sale or wood steam boiler)?

A1: Electric steam boilers offer several distinct advantages: zero on-site emissions, near 99% energy efficiency, precise temperature and pressure control, faster startup/shutdown times, significantly lower maintenance due to fewer moving parts and no combustion byproducts, and enhanced safety by eliminating combustion risks. They also don't require fuel storage or exhaust systems.

Q2: How is the efficiency of an electric steam boiler measured and maintained?

A2: Efficiency is measured by the ratio of heat output (steam energy) to electrical energy input. Electric boilers achieve efficiencies close to 99% because nearly all electrical energy is converted directly into heat within the water. Maintenance involves regular feedwater treatment to prevent scale buildup on heating elements, periodic blowdown, and checking electrical connections and safety devices. Proper insulation and a well-calibrated thermostat for steam boiler are also crucial for maintaining optimal efficiency.

Q3: Can electric steam boilers be integrated with existing plant control systems?

A3: Yes, modern electric steam boilers are designed for seamless integration. They typically feature advanced PLC controls with communication ports (e.g., Modbus, Ethernet/IP, Profibus) that allow them to interface with a facility's Distributed Control System (DCS) or Supervisory Control and Data Acquisition (SCADA) systems for centralized monitoring and control. This enhances operational visibility and enables automated process management.

Q4: What is the typical lead time for a new electric steam boiler, and what kind of warranty can be expected?

A4: Lead times vary based on boiler size, complexity, and customization. Standard units generally take 8-12 weeks from order to shipment. Highly customized or very large industrial units might require 14-20 weeks. Regarding warranties, reputable electric steam boiler manufacturers typically offer a 1-year warranty on the complete system and a more extended warranty, often 3-5 years, on the pressure vessel itself, reflecting its robust construction.

Conclusion: Powering Industry with Clean, Efficient Steam

Electric steam boilers represent a significant leap forward in industrial heating technology, perfectly aligning with global mandates for sustainability and operational efficiency. Their ability to deliver clean, precise, and reliable steam without the complexities and emissions of combustion-based systems makes them an increasingly preferred choice across diverse sectors.

For B2B stakeholders, partnering with experienced and authorized electric steam boiler manufacturers is not just about acquiring equipment; it's about securing a long-term, high-performance solution backed by expert engineering, rigorous quality control, and unwavering after-sales support. As industries continue to evolve, electric steam boilers will undoubtedly remain at the core of efficient, environmentally responsible process heating.

References

- Grand View Research. (2023). Industrial Boiler Market Size, Share & Trends Analysis Report By Fuel (Natural Gas, Oil, Coal, Others), By Technology (Fire-tube, Water-tube, Electric), By End-use (Food & Beverage, Chemicals, Refinery), By Region, And Segment Forecasts, 2023 - 2030.

- ASME Boiler and Pressure Vessel Code (BPVC), Section I: Rules for Construction of Power Boilers.

- European Parliament and Council. (2014). Directive 2014/68/EU on the harmonisation of the laws of the Member States relating to the making available on the market of pressure equipment (recast).

- International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems - Requirements.

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025