Electric Steam Boiler Manufacturers - Trusted Industrial Solutions

Industry Trends in Electric Steam Boiler Manufacturing

The industrial landscape is undergoing a profound transformation, driven by imperatives of energy efficiency, reduced carbon emissions, and operational safety. In this context, the demand for advanced steam generation solutions, particularly from electric steam boiler manufacturers, is experiencing significant growth. Electric boilers offer a compelling alternative to traditional fossil-fuel fired systems, aligning with global decarbonization efforts and increasingly stringent environmental regulations. Key trends include the integration of smart control systems, enhanced modularity for scalable applications, and a focus on high-efficiency designs that minimize energy waste.

The market is witnessing a shift towards higher voltage systems (e.g., 6.6 kV, 11 kV) to accommodate larger capacity requirements in heavy industries, further emphasizing the expertise required from leading manufacturers. Innovations in heating element technology, such as the use of specialized alloys and improved insulation, are driving performance enhancements and extended service life. Furthermore, the rising availability and economic viability of renewable electricity sources make electric steam boilers an increasingly attractive option for industries seeking to achieve sustainability goals. This includes sectors like petrochemicals, food & beverage, pharmaceuticals, and general manufacturing, all striving for cleaner production processes.

Relatedly, the market for gas steam boiler for sale continues to evolve with advancements in combustion efficiency and emission control, often complementing electric solutions in hybrid systems. The importance of a robust steam boiler heat exchanger cannot be overstated, as its design directly impacts overall system efficiency. For steam boiler industrial applications, reliability and continuous operation are paramount, leading to robust engineering standards. Advanced thermostat for steam boiler systems now integrate predictive maintenance capabilities, significantly reducing downtime. The distinctions between a water tube steam boiler and a fire tube boiler are critical in specific high-pressure, high-capacity scenarios. Even legacy systems, such as the weil mclain eg 40 steam boiler, are subject to modern control upgrades and efficiency considerations. The niche for wood steam boiler systems persists in regions with abundant biomass resources, emphasizing a diverse market for steam generation.

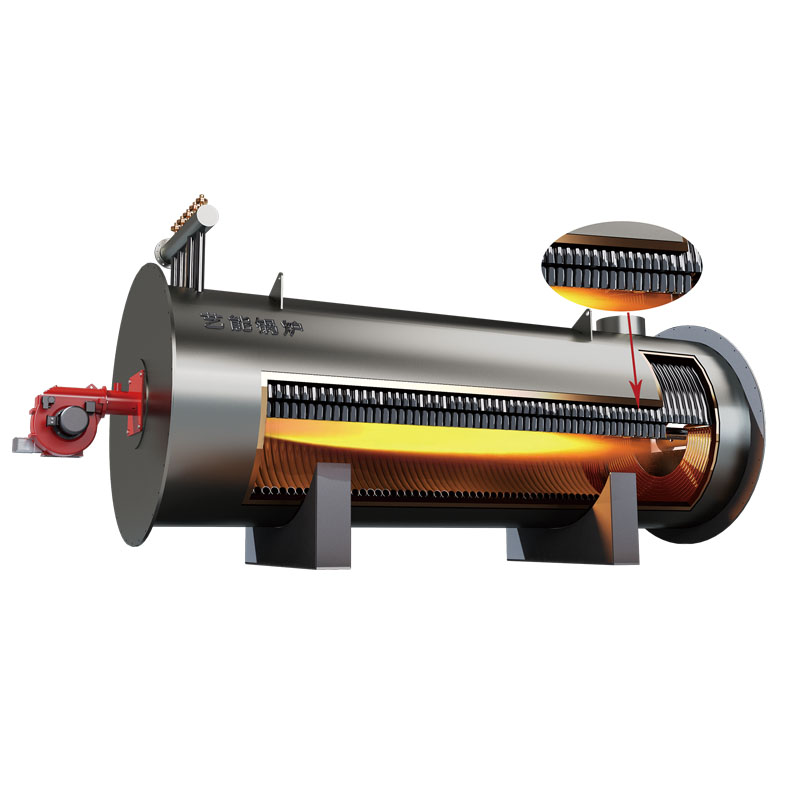

Manufacturing Process Flow of Electric Steam Boilers

The production of high-quality electric steam boilers by leading electric steam boiler manufacturers involves a meticulously controlled, multi-stage process designed to ensure safety, efficiency, and longevity. This process begins with material selection and extends through rigorous testing.

1. Material Selection & Preparation

- Pressure Vessel Steel: High-grade carbon steel (e.g., SA-516 Grade 70) or low-alloy steel for pressure parts, selected for its tensile strength, yield strength, and resistance to creep at elevated temperatures. These materials meet ASME Boiler and Pressure Vessel Code standards.

- Heating Elements: Incoloy 800 or 840 for tubular heating elements, chosen for superior corrosion resistance and high-temperature performance, ensuring a long service life.

- Insulation: High-density mineral wool or ceramic fiber blankets for thermal efficiency, minimizing heat loss to the ambient environment.

- Piping & Valves: Stainless steel or forged carbon steel, depending on pressure and temperature requirements, sourced from certified suppliers to ANSI standards.

2. Pressure Vessel Fabrication

This critical stage involves the precise forming and welding of the boiler shell and heads.

- Cutting & Forming: CNC plasma or laser cutting ensures precise dimensions. Plates are then roll-formed into cylindrical sections.

- Welding: Automated submerged arc welding (SAW) and manual shielded metal arc welding (SMAW) or gas tungsten arc welding (GTAW) are employed by certified welders (ASME Section IX). Full penetration welds are standard.

- Non-Destructive Testing (NDT): Radiographic (X-ray) or ultrasonic testing is performed on all critical welds to detect internal flaws, conforming to ISO 17636 and ASME Section V.

- Post-Weld Heat Treatment (PWHT): For thicker sections or specific material grades, PWHT is conducted to relieve residual stresses and improve material toughness.

3. Heating Element & Electrical System Integration

- Element Installation: Heating elements are precisely mounted into the boiler chamber, often utilizing robust flange connections for ease of maintenance.

- Control Panel Assembly: Integration of advanced PLC (Programmable Logic Controller) systems, SCR (Silicon Controlled Rectifier) power controls for precise temperature and pressure regulation, safety interlocks, and HMI (Human-Machine Interface) for operator interface. Wiring conforms to UL/IEC standards.

- Instrumentation: Installation of pressure transmitters, temperature sensors (RTDs/thermocouples), level probes, and safety relief valves, all calibrated to industry standards.

4. Insulation & Jacketing

The boiler is heavily insulated to minimize heat loss, then clad with a protective outer jacket, typically from stainless steel or painted mild steel, for durability and aesthetics.

5. Testing & Quality Assurance

Each boiler undergoes extensive testing before shipment to ensure compliance with design specifications and safety regulations.

- Hydrostatic Testing: The pressure vessel is subjected to pressures significantly higher than its maximum allowable working pressure (MAWP) to verify structural integrity and leak-tightness, per ASME Section I.

- Functional Testing: All electrical components, control systems, safety interlocks, and operational sequences are tested under simulated load conditions. This includes verifying water level control, pressure control, and safety shutdowns.

- Performance Testing: Efficiency, steam quality (dryness fraction), and operational stability are assessed to meet guaranteed parameters.

- Final Inspection: A comprehensive visual and dimensional inspection ensures adherence to all drawing specifications and quality standards.

Service Life & Target Industries: A well-manufactured electric steam boiler typically offers a service life of 20-30 years with proper maintenance. These boilers excel in target industries such as:

- Petrochemical: For precise temperature control in processes, trace heating, and reactor jacket heating, where high purity steam is essential and flame is prohibited.

- Pharmaceuticals: For sterilization, humidification, and process heating requiring ultra-clean, contaminant-free steam, meeting cGMP standards.

- Food & Beverage: For cooking, pasteurization, sterilization of equipment, and cleaning-in-place (CIP) systems, requiring reliable and safe steam generation.

- Water Supply & Drainage: For heating and sterilization in wastewater treatment plants, and humidification in controlled environments.

- Textile: For dyeing, drying, and finishing processes, where consistent steam quality is crucial.

Advantages in Typical Application Scenarios: Electric boilers offer significant advantages:

- Energy Saving: Near 100% thermal efficiency as all electrical energy is converted directly into heat within the boiler water. This reduces operational costs, particularly where electricity tariffs are favorable or renewable energy sources are utilized.

- Corrosion Resistance: Absence of combustion byproducts (like sulfur oxides) eliminates corrosive attacks on internal surfaces associated with flue gases, extending boiler life. Proper water treatment further enhances this.

- Environmental Purity: Zero direct on-site emissions of NOx, SOx, CO2, or particulate matter, contributing significantly to cleaner air and meeting strict environmental regulations.

- Operational Safety: No risk of fuel explosions or flammability issues associated with gas or oil-fired systems. Advanced electrical interlocks and safety features ensure secure operation.

- Precision Control: SCR-based power modulation allows for extremely precise temperature and pressure control, crucial for sensitive industrial processes.

Technical Specifications and Parameters

Modern electric steam boilers are engineered to deliver reliable performance across a range of industrial demands. Understanding their core technical specifications is crucial for optimal system selection and integration. The following table illustrates typical parameters for industrial electric steam boilers.

| Parameter | Value Range | Unit/Description |

|---|---|---|

| Steam Output Capacity | 50 - 6,000 | kg/hr (110 - 13,228 lbs/hr) |

| Operating Pressure | 0.7 - 2.5 | MPaG (100 - 360 PSIG) |

| Thermal Efficiency | 98 - 99.5 | % |

| Electrical Power Supply | 220V - 11kV | 3-Phase, 50/60 Hz |

| Heating Element Material | Incoloy 800/840 | High-temperature, corrosion-resistant alloy |

| Control System | PLC with HMI | SCR power control, Modbus/Ethernet communication |

| Water Treatment Requirement | Softened/DM Water | TDS |

| Safety Features | Multiple | Over-pressure, low water level, over-current, phase loss protection |

The robust design often features a horizontal or vertical orientation depending on space constraints and capacity. Horizontal designs typically offer larger steam disengagement areas, contributing to higher steam quality. The material of construction, particularly for the pressure vessel, adheres strictly to international codes such as ASME, PED, or other regional standards, ensuring integrity under operational stresses.

Advanced control systems, a hallmark of modern electric steam boilers, often include features like proportional-integral-derivative (PID) control loops for precise output modulation, automatic blowdown for maintaining water quality, and remote monitoring capabilities. These features not only optimize performance but also reduce the need for constant manual intervention, enhancing operational efficiency and safety.

Application Scenarios and Case Studies

Electric steam boilers are versatile, finding critical roles across diverse industrial sectors where clean, reliable, and precisely controlled steam is paramount. Their adaptability makes them suitable for applications ranging from sterilization in healthcare to process heating in manufacturing.

Pharmaceutical Manufacturing

In pharmaceutical facilities, ultra-pure steam is essential for sterilization of equipment (autoclaves, reactors), humidification in cleanrooms, and heating of process vessels. Electric boilers are preferred due to their ability to produce clean steam without combustion byproducts, adhering to cGMP (current Good Manufacturing Practices) and FDA requirements. A major pharmaceutical company integrated a 1,500 kg/hr electric steam boiler to support its aseptic filling lines, achieving a consistent steam quality of 99.8% dryness fraction, vital for contamination control. This eliminated the need for a separate flue gas exhaust system, simplifying facility design and reducing maintenance.

Food and Beverage Industry

For pasteurization, cooking, sterilization of packaging, and CIP (Clean-in-Place) systems, food and beverage companies require reliable steam. A large dairy processing plant installed two 2,500 kg/hr electric boilers to replace aging oil-fired units. This transition resulted in a 30% reduction in operating costs due to favorable electricity tariffs and near-perfect thermal efficiency. Furthermore, the absence of combustion emissions directly contributed to a cleaner production environment, positively impacting their brand's sustainability profile. The precise temperature control allowed by SCR systems improved product consistency in heat treatment processes.

Chemical and Petrochemical Processing

In environments where flammable materials are present, electric boilers offer a safer heating solution, eliminating open flames. They are used for reactor jacket heating, distillation processes, and trace heating of pipelines to prevent fluid solidification. A specialty chemical manufacturer deployed a 3,000 kg/hr high-pressure electric boiler for a new production line, specifically chosen for its inherent safety features and ability to operate within hazardous area classifications. The compact footprint of the electric boiler also allowed for integration into existing plant infrastructure without extensive modifications.

Textile Industry

Steam is crucial for dyeing, drying, and finishing processes in textile manufacturing. Consistency in temperature and pressure directly impacts product quality. An apparel manufacturer switched to electric steam boilers for their dyeing operations, experiencing fewer batch variations due to the stable steam supply and superior control offered by the electric units. This transition also allowed them to align with corporate sustainability mandates by significantly reducing their carbon footprint.

Vendor Comparison and Customized Solutions

Choosing the right partner among electric steam boiler manufacturers is a strategic decision that impacts long-term operational costs, reliability, and compliance. Key differentiators include product innovation, customization capabilities, after-sales support, and adherence to international standards.

| Feature/Vendor Focus | Vendor A (e.g., European Specialist) | Vendor B (e.g., North American Leader) | Vendor C (e.g., Asian Innovator) |

|---|---|---|---|

| Standard Capacities (kg/hr) | 100 - 5,000 | 50 - 6,000 | 80 - 4,500 |

| Max. Operating Pressure (MPaG) | 2.0 | 2.5 | 1.6 |

| Thermal Efficiency (%) | ~99 | >99.5 | ~98 |

| Control System | Siemens S7 PLC, HMI | Allen-Bradley PLC, SCADA-ready | Custom PLC, basic HMI |

| Certifications | PED, CE, ISO 9001 | ASME, UL, CSA, ISO 9001 | Local standards, ISO 9001 |

| Key Advantage | Compact design, high integration | Robust build, high pressure, advanced diagnostics | Cost-effective, rapid deployment |

| Customization Level | Moderate | High | Basic |

Customized Solutions: A significant advantage offered by leading electric steam boiler manufacturers is the ability to provide highly customized solutions. This is crucial for industries with unique spatial constraints, specific steam parameters (e.g., superheated steam), specialized control integration requirements, or demanding environmental conditions. Customization can involve:

- Voltage and Power Configuration: Tailoring to specific regional grid voltages (e.g., 400V, 480V, 6.6kV, 11kV) and power requirements for seamless integration.

- Material Upgrades: Utilizing specialized alloys for enhanced corrosion resistance in aggressive environments or for ultra-high purity applications.

- Control System Integration: Custom programming of PLCs to interface with existing plant DCS (Distributed Control System), SCADA, or building management systems. This might include specific data logging, remote diagnostics, or sequence controls.

- Skid-Mounted Solutions: Providing complete boiler rooms on a skid, including water treatment, condensate return, and deaerators, for rapid deployment and minimal on-site installation work.

- Hazardous Area Compliance: Designing boilers to meet ATEX, IECEx, or NFPA regulations for operation in classified hazardous zones.

- Steam Quality Enhancement: Incorporating specialized steam separators or superheaters to achieve specific steam dryness fractions or superheat temperatures.

This bespoke approach ensures that the boiler system is perfectly aligned with the client's operational objectives, optimizing performance and maximizing return on investment. Manufacturers with extensive engineering capabilities and a proven track record in custom projects are often preferred for complex industrial applications.

Trustworthiness and Support Information

Frequently Asked Questions (FAQ)

Q1: What is the typical lead time for an industrial electric steam boiler?

A: Standard models typically have a lead time of 12-16 weeks from order confirmation to shipment. Customized solutions may require 18-24 weeks due to design, material sourcing, and specialized fabrication.

Q2: What kind of water treatment is required for electric steam boilers?

A: To prevent scaling and corrosion, softened or demineralized (DM) water is highly recommended. Typical requirements include hardness less than 2 ppm and total dissolved solids (TDS) below 100 ppm, with pH maintained between 8.5-10.0. Proper water chemistry significantly extends the life of heating elements and the boiler vessel.

Q3: Are electric steam boilers suitable for continuous operation?

A: Yes, modern industrial electric steam boilers are designed for continuous, 24/7 operation. With robust heating elements and advanced control systems, they offer exceptional reliability and minimal downtime, provided proper maintenance and water treatment schedules are followed.

Q4: What are the main safety features of these boilers?

A: Safety is paramount. Key features include multiple pressure relief valves, high/low water level cut-offs, over-temperature protection, emergency stop buttons, interlocks for heating element operation, and comprehensive electrical fault protection (over-current, phase loss). All systems comply with stringent industry safety standards like ASME, UL, or PED.

Lead Time & Fulfillment

Our commitment to timely delivery is a cornerstone of our service. Standard electric steam boiler configurations typically ship within 12-16 weeks. For highly customized solutions, a detailed project timeline is provided during the proposal stage, generally ranging from 18-24 weeks. We maintain rigorous project management and quality control throughout the manufacturing and assembly process, ensuring that delivery schedules are met without compromising product excellence. Expedited options may be available depending on manufacturing capacity and material availability, subject to specific project requirements.

Warranty Commitments

All our industrial electric steam boilers come with a comprehensive warranty package, typically including:

- 24-month warranty on the pressure vessel from the date of installation or 30 months from shipment, whichever comes first.

- 12-month warranty on electrical components and auxiliary equipment.

Our warranty covers defects in materials and workmanship under normal operating conditions. Detailed warranty terms and conditions are provided with each quotation and order, ensuring full transparency and peace of mind.

Customer Support and After-Sales Service

Our commitment extends beyond product delivery. We offer extensive customer support and after-sales services designed to maximize your boiler's operational lifespan and efficiency. This includes:

- Technical Helpline: 24/7 access to experienced boiler technicians for immediate troubleshooting and guidance.

- On-site Commissioning: Our certified engineers provide expert installation supervision and commissioning services to ensure optimal setup and initial operation.

- Preventative Maintenance Programs: Tailored service contracts to ensure regular inspections, component checks, and proactive replacements, minimizing unscheduled downtime.

- Spare Parts Availability: A comprehensive inventory of genuine spare parts, guaranteeing rapid delivery and minimizing operational interruptions.

- Operator Training: On-site or remote training sessions for your personnel on safe operation, basic maintenance, and troubleshooting procedures.

- Remote Monitoring & Diagnostics: Advanced systems allowing for real-time performance monitoring and predictive maintenance alerts.

We are dedicated to building long-term partnerships, providing the support necessary to maintain peak performance and operational continuity for our clients worldwide.

Conclusion

The landscape of industrial steam generation is irrevocably shifting towards more sustainable, efficient, and safer solutions. Electric steam boiler manufacturers are at the forefront of this evolution, offering advanced systems that meet the stringent demands of modern industry. From precision engineering and robust material selection to sophisticated control systems and comprehensive after-sales support, these manufacturers deliver critical infrastructure that empowers industries to achieve their operational and environmental goals. The transition to electric steam boilers represents not just a technological upgrade, but a strategic investment in future-proof, environmentally responsible industrial operations.

References

- American Society of Mechanical Engineers (ASME). Boiler and Pressure Vessel Code, Section I: Rules for Construction of Power Boilers. ASME International, 2021.

- European Committee for Standardization (CEN). EN 12953: Shell boilers. CEN, 2012.

- United States Department of Energy. Steam Best Practices: Steam System Assessment Tool. DOE, 2020.

- International Organization for Standardization (ISO). ISO 9001: Quality management systems – Requirements. ISO, 2015.

- The Engineering ToolBox. Boiler Efficiency. engineeringtoolbox.com. Accessed [Current Date].

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025