Electric steam boiler manufacturers—efficient, turnkey?

[electric steam boiler manufacturers,gas steam boiler for sale,steam boiler heat exchanger,steam boiler industrial,thermostat for steam boiler,water tube steam boiler,weil mclain eg 40 steam boiler,wood steam boiler] is a key solution in the manufacturing industry, specifically within General equipment manufacturing industry and Manufacturing of boilers and auxiliary equipment. This article explores how Hebei Yineng Boiler Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- [electric steam boiler manufacturers,gas steam boiler for sale,steam boiler heat exchanger,steam boiler industrial,thermostat for steam boiler,water tube steam boiler,weil mclain eg 40 steam boiler,wood steam boiler] Overview

- Benefits & Use Cases of [electric steam boiler manufacturers,gas steam boiler for sale,steam boiler heat exchanger,steam boiler industrial,thermostat for steam boiler,water tube steam boiler,weil mclain eg 40 steam boiler,wood steam boiler] in Manufacturing of boilers and auxiliary equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on [electric steam boiler manufacturers,gas steam boiler for sale,steam boiler heat exchanger,steam boiler industrial,thermostat for steam boiler,water tube steam boiler,weil mclain eg 40 steam boiler,wood steam boiler] from Hebei Yineng Boiler Co., Ltd

[electric steam boiler manufacturers,gas steam boiler for sale,steam boiler heat exchanger,steam boiler industrial,thermostat for steam boiler,water tube steam boiler,weil mclain eg 40 steam boiler,wood steam boiler] Overview

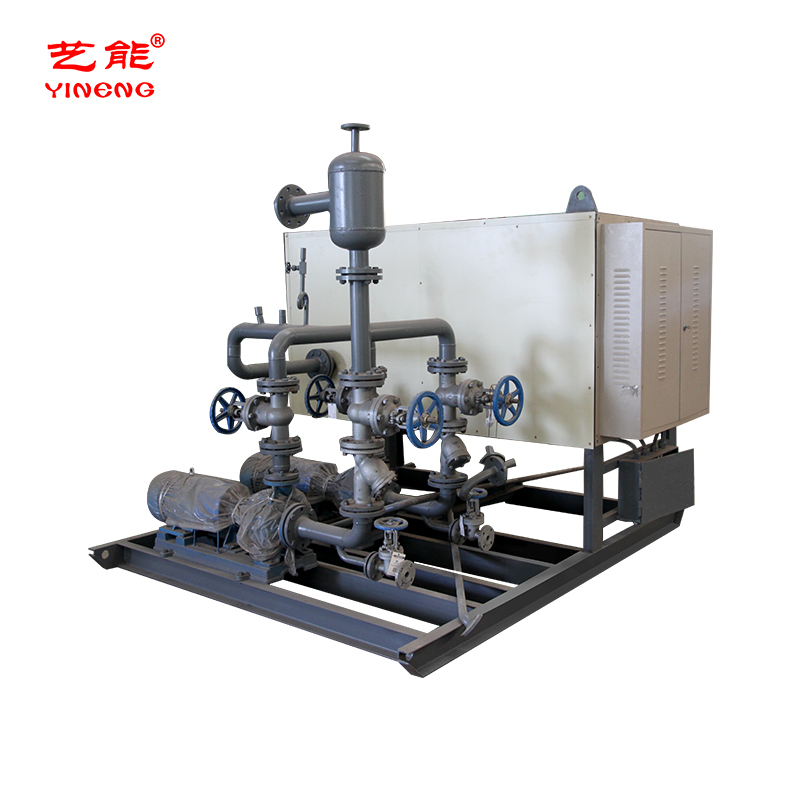

Industrial steam generation underpins countless processes—from sterilization and CIP to molding, drying, and power co-generation. When B2B buyers search for solutions, they often compare electric steam boiler manufacturers, evaluate a gas steam boiler for sale, or assess whether a water tube steam boiler is a better fit than a fire-tube design. A modern steam boiler industrial system is built around a robust pressure vessel, a high-efficiency steam boiler heat exchanger, and intelligent controls including a thermostat for steam boiler stability and safety interlocks.

Hebei Yineng Boiler Co., Ltd engineers thermal systems that align with demanding plant standards, offering electric heating thermal oil solutions and complementary steam technologies to match different duty cycles, fuels, and footprints. Whether you’re upgrading from a unit in the Weil-McLain EG 40 steam boiler class or planning a new line, Yineng’s engineering team helps right-size capacity, pressure, and turndown to reduce losses and improve uptime. For operations with sustainable fuel strategies, a wood steam boiler or biomass-ready system can also be considered as part of a diversified energy mix.

Benefits & Use Cases of [electric steam boiler manufacturers,gas steam boiler for sale,steam boiler heat exchanger,steam boiler industrial,thermostat for steam boiler,water tube steam boiler,weil mclain eg 40 steam boiler,wood steam boiler] in Manufacturing of boilers and auxiliary equipment

In Manufacturing of boilers and auxiliary equipment, steam systems must deliver fast start-up, steady pressure, and uncompromising safety. A water tube steam boiler excels in high-pressure, high-capacity scenarios with rapid response—ideal for metal forming, chemical reactors, and petrochemical utilities. Facilities prioritizing simplicity and smaller footprints often evaluate a compact gas steam boiler for sale with integrated economizer (steam boiler heat exchanger) to reclaim flue heat and boost efficiency. When electrical infrastructure is robust or emissions limits are stringent, electric options shine with near-zero local emissions and minimal mechanical complexity.

Hebei Yineng Boiler Co., Ltd supports these use cases with application-specific design, from PLC/HMI automation to remote diagnostics, O2 trim, and multistage or fully modulating control that works in concert with the thermostat for steam boiler logic. For biomass users, a wood steam boiler can stabilize fuel costs and leverage local residues. For retrofit projects replacing units in the Weil-McLain EG 40 steam boiler range, Yineng helps map piping, condensate handling, and controls integration to reduce downtime. The result: safer operations, higher thermal efficiency, and consistent quality output across shifts.

Cost, Maintenance & User Experience

Total cost of ownership (TCO) hinges on fuel or electricity tariffs, run-hours, maintenance labor, and unplanned downtime. Electric systems tend to lower routine maintenance (no burners, no flue gas path), while gas-fired units typically offer lower energy cost where gas pricing is favorable. A right-sized steam boiler industrial design with proper turndown minimizes short-cycling and extends component life. Adding an economizer or enhanced steam boiler heat exchanger can yield measurable fuel savings, improving ROI over a 12–36 month horizon depending on load profile.

From the user perspective, standardizing spares, water treatment, and preventative maintenance is critical. Hebei Yineng Boiler Co., Ltd emphasizes serviceability: accessible tube bundles on water tube steam boiler configurations, clear HMI alarms tied to the thermostat for steam boiler setpoints, and recommended inspection intervals for valves, level controls, and feedwater systems. Customers in general equipment manufacturing report improved uptime after implementing automated blowdown, condensate recovery, and training programs delivered alongside commissioning. Clear documentation and remote support reduce MTTR and help teams maintain safe, efficient operations throughout the lifecycle.

Sustainability & Market Trends in manufacturing

Decarbonization is accelerating across global manufacturing. Plants are evaluating electrification where grids are cleaner, adopting low-NOx burners, and pairing gas systems with high-grade heat recovery. Regulations such as local emissions caps, efficiency standards, and safety codes push continuous improvement in steam boiler industrial deployments. In parallel, circularity initiatives encourage fuel diversification—making a wood steam boiler or biomass hybrid attractive for agro-processing and timber-related industries with reliable feedstock.

Hebei Yineng Boiler Co., Ltd aligns with these trends through efficiency-first engineering, robust insulation, smart controls, and options that facilitate future upgrades. Whether you’re sourcing from electric steam boiler manufacturers or comparing a gas steam boiler for sale today with a potential electric transition later, Yineng prioritizes modularity, data visibility, and lifecycle sustainability. By optimizing the steam boiler heat exchanger and integrating energy recovery, plants can cut Scope 1 emissions per unit output and future-proof assets against tightening regulations and rising energy costs.

Conclusion on [electric steam boiler manufacturers,gas steam boiler for sale,steam boiler heat exchanger,steam boiler industrial,thermostat for steam boiler,water tube steam boiler,weil mclain eg 40 steam boiler,wood steam boiler] from Hebei Yineng Boiler Co., Ltd

For B2B teams evaluating electric steam boiler manufacturers, a gas steam boiler for sale, or advanced water tube steam boiler options, partnering with Hebei Yineng Boiler Co., Ltd delivers dependable performance, safety, and efficiency. From controls like a thermostat for steam boiler stability to optimized steam boiler heat exchanger designs—and even biomass-ready wood steam boiler strategies—Yineng supports your productivity and compliance goals with proven engineering and attentive service.

Contact us: email: leesonzhou@aliyun.com

Visit our website: https://www.ynboilers.com

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025