Electric Steam Boiler Manufacturers | High-Efficiency OEM

An Insider’s Take on Electric Steam Boiler Manufacturers (and a Smarter Alternative)

If you’re scanning the market of electric steam boiler manufacturers, you’ve probably noticed a quiet shift. Yes, steam is still king for clean heat in food, pharma, and light industrial processes. However, more buyers are asking for tighter temperature control, lower maintenance, and a practical route to decarbonize. That’s where electric thermal oil systems sneak into the conversation—sometimes the better fit, depending on the process.

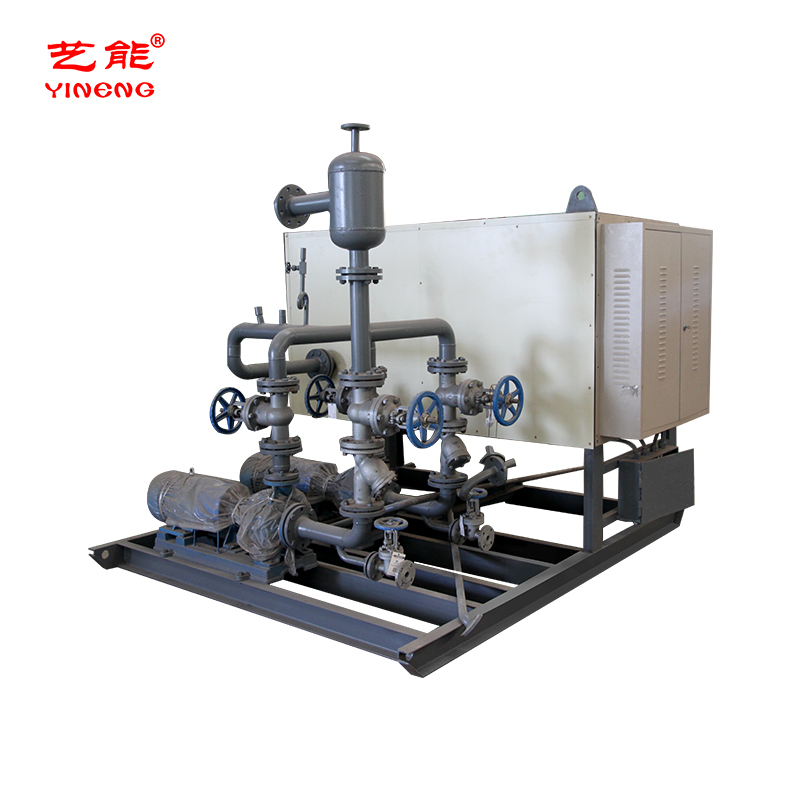

Product spotlight: Electric heating thermal oil boiler (from Wuqiao, Hebei, China)

I visited Wuqiao a while back—windy plains, skilled fabricators, and, to be honest, a lot of quiet competence. The electric heating and heat transfer oil furnace there uses thermal oil as the carrier, delivering stable heat without the complexities of steam traps, blowdown, or condensate return. For processes that need 150–320°C with tight control, that’s gold.

| Spec | Electric heating thermal oil boiler |

|---|---|

| Heat medium | Synthetic heat transfer oil |

| Typical output | 60–2,000 kW (custom up to ≈4 MW) |

| Max oil temp | ≈320°C (real‑world use may vary by fluid) |

| Electrical efficiency | Up to 98–99% to heat |

| Control | PID, SSR/thyristor, ΔT monitoring, data logging |

| Certs | ASME/PED (vessel scope), UL 499/IEC 60204-1 (electrical), ISO 9001 (factory) |

| Origin | Wuqiao, Hebei, China |

Industry trends I keep hearing

- Electrification is accelerating; many buyers want zero on‑site NOx and future carbon credit eligibility.

- Steam still dominates CIP, humidification, and sterilization. But for thermal oil users—coating lines, die casting, asphalt plants—electric can be easier to own.

- Controls matter. Ramp control, soft‑start, and remote monitoring used to be nice-to-haves; now they’re baseline.

How it’s built (process flow)

- Materials: pressure boundary in Q235B/SA‑516 or equivalent; heater sheath 316L; high-temp seals; rock-wool insulation.

- Methods: automated welding, oil-side flushing, electrical busbar sizing per IEC 60204‑1, thermal validation.

- Testing: hydrostatic test per ASME/PED; NDT where required; insulation resistance test; factory FAT with PID tuning.

- Standards: ASME BPVC scope as applicable, UL 499 heating equipment, CE/PED 2014/68/EU, ISO 9001 QMS.

- Service life: ≈10–15 years with oil analysis, strainer cleaning, and annual electrical inspections.

- Industries: chemicals, textiles, food processing (non-contact), printing, laminating, bitumen, die-casting molds.

When to pick steam vs. thermal oil

Need saturated steam for sterilization or humidification? Talk to electric steam boiler manufacturers. Need uniform 200–300°C without water chemistry headaches? A thermal oil system may save you time and, frankly, grey hairs.

| Vendor (public info) | Region | Medium | Typical kW range | Certs (varies) | Lead time |

|---|---|---|---|---|---|

| YN Boilers | China | Thermal oil | 60–2,000+ | ASME/PED, ISO | ≈4–10 wks |

| Fulton | US/EU | Steam | 15–1,000+ | ASME, CE | Varies |

| Chromalox | US/global | Steam/Oil | 10–4,000+ | UL, CE | Varies |

| PARAT | Norway | Steam | 100–5,000+ | CE/PED | Project-based |

Indicative, compiled from public brochures; confirm specs per model and jurisdiction.

Field notes and feedback

Users tell me the electric thermal oil units run “quiet and boring”—which is a compliment. One textile finisher reported ±1.5°C stability at 220°C. A packaging line shaved 30–40% maintenance time by ditching steam traps. Power costs? That’s local grid math, but pairing with off‑peak tariffs and PV helps.

Customization checklist

- Heater banks staged or thyristor for smooth ramp.

- ATEX/IECEx options for hazardous zones (if required).

- Redundant pumps, SS coil heaters, and remote SCADA.

- Factory FAT with witnessed test data (insulation resistance ≥1 MΩ, pressure test per code).

Quick case snippet

A regional laminating plant replaced a 1.2‑MW gas thermal oil heater with a 1‑MW electric unit. Result: start‑to‑temp in ≈45 minutes, oil life extended via quarterly TAN checks, and near‑silent operation. Maintenance lead’s words, not mine: “We stopped chasing leaks.” If your team is talking to electric steam boiler manufacturers for 180–220°C duties, at least price an electric thermal oil option.

Final thought

Steam or thermal oil—it’s not dogma, it’s process fit. Just make sure the unit you choose is certified in your region, tested per code, and sized with future electrification in mind.

- ASME Boiler and Pressure Vessel Code (BPVC). https://www.asme.org/codes-standards

- UL 499: Electric Heating Appliances. https://standardscatalog.ul.com

- EU Pressure Equipment Directive 2014/68/EU (PED). https://single-market-economy.ec.europa.eu

- IEC 60204-1: Safety of machinery—Electrical equipment. https://webstore.iec.ch

- U.S. DOE Industrial Decarbonization Roadmap (2022). https://www.energy.gov

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025