Exploring the Efficiency and Performance of 175% Rated 20000 BTU Steam Boiler Manufacturers

The Role of 175% Capacity 20000 BTU Steam Boiler Factories in Modern Industry

In today's industrial landscape, the demand for efficient and reliable heating solutions has never been greater. Among the various options available, steam boilers stand out as a crucial component in many production processes. One notable category is the 175% capacity 20,000 BTU steam boiler, which has become a focal point for factories aiming to optimize their operations.

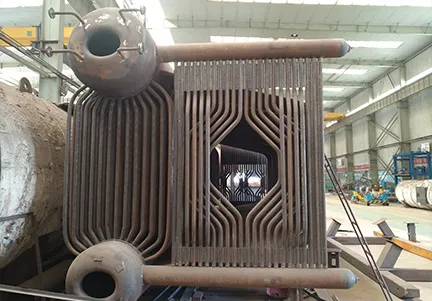

A steam boiler operates by converting water into steam through the application of heat. The steam produced is then used in various applications across industries, including power generation, chemical processing, and food production. The efficiency of this conversion process is significantly influenced by the boiler's capacity and thermal output. Boilers rated at 20,000 BTUs (British Thermal Units) are designed to deliver a substantial amount of heat energy, making them suitable for medium-sized industrial tasks.

Efficiency and Performance

The designation of a boiler as 175% capacity implies that it can operate at a higher output than its nominal rating when necessary. This feature is particularly beneficial in factories where production demands can fluctuate unexpectedly. By being capable of handling peaks in demand, these boilers help maintain a consistent and reliable supply of steam, reducing the risk of production downtime.

Moreover, the efficiency of a steam boiler is not solely determined by its capacity. Factors such as fuel type, combustion efficiency, and heat recovery mechanisms also play essential roles. Modern factories increasingly adopt advanced technologies that enhance the efficiency of their 20,000 BTU steam boilers, making them more environmentally friendly and cost-effective. By utilizing options such as natural gas or biomass as fuel, factories can reduce their carbon footprint while benefiting from lower fuel costs.

175 000 btu steam boiler factories

Application Versatility

Factories across a wide range of industries utilize steam boilers for various applications. In the food processing sector, for example, steam is essential for cooking, sterilizing equipment, and heating processes. In chemical manufacturing, steam is used in distillation, extraction, and other thermal operations. The versatility of 20,000 BTU steam boilers makes them suitable for these diverse roles, ensuring that they can adapt to the specific needs of different production environments.

Additionally, the ability to integrate these boilers into existing factory systems enhances their appeal. Many modern boilers come equipped with automation features, allowing for remote monitoring and control. This capability supports better management of energy consumption, helping factories to operate more efficiently and reduce operational costs.

Future Trends

As industries increasingly focus on sustainability and efficiency, the demand for advanced steam boilers is likely to grow. Innovations such as condensing technology, which captures waste heat from the exhaust, can significantly boost the overall efficiency of a steam boiler system. Furthermore, the incorporation of IoT (Internet of Things) technology allows for real-time data analysis, enabling predictive maintenance and further enhancing the longevity and efficiency of the boiler.

In conclusion, the 175% capacity 20,000 BTU steam boiler represents an essential asset for modern factories striving for efficiency, reliability, and sustainability. Its ability to adapt to varying production needs, combined with technological advancements, positions it as a pivotal element in the continuous evolution of industrial processes. As industries advance into the future, the role of these steam boilers will undoubtedly expand, contributing to more sustainable and efficient manufacturing practices.

-

Efficient Waste Heat Boilers: Energy Recovery SolutionsNewsAug.19,2025

-

Industrial Thermal Oil Boilers | Efficient & Reliable HeatingNewsAug.18,2025

-

Electric Steam Boiler Manufacturers: Efficient & Reliable SolutionsNewsAug.17,2025

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.15,2025

-

Leading Electric Steam Boiler Manufacturers for IndustryNewsAug.14,2025

-

Buy Waste Heat Boilers: Custom, Efficient & Affordable SolutionsNewsAug.13,2025