Jun . 18, 2024 03:58

Back to list

Factories using natural gas for hot water boiler production

Natural Gas Fired Hot Water Boiler Factories A Pillar of Modern Heating Solutions

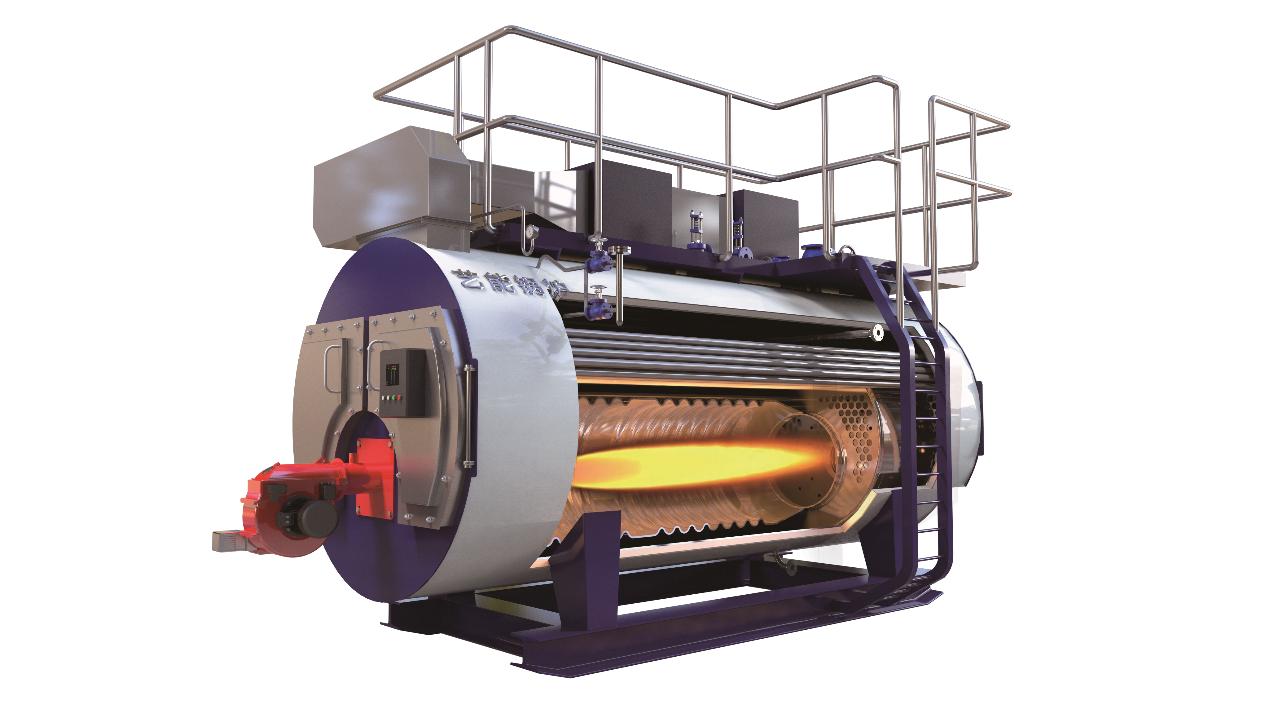

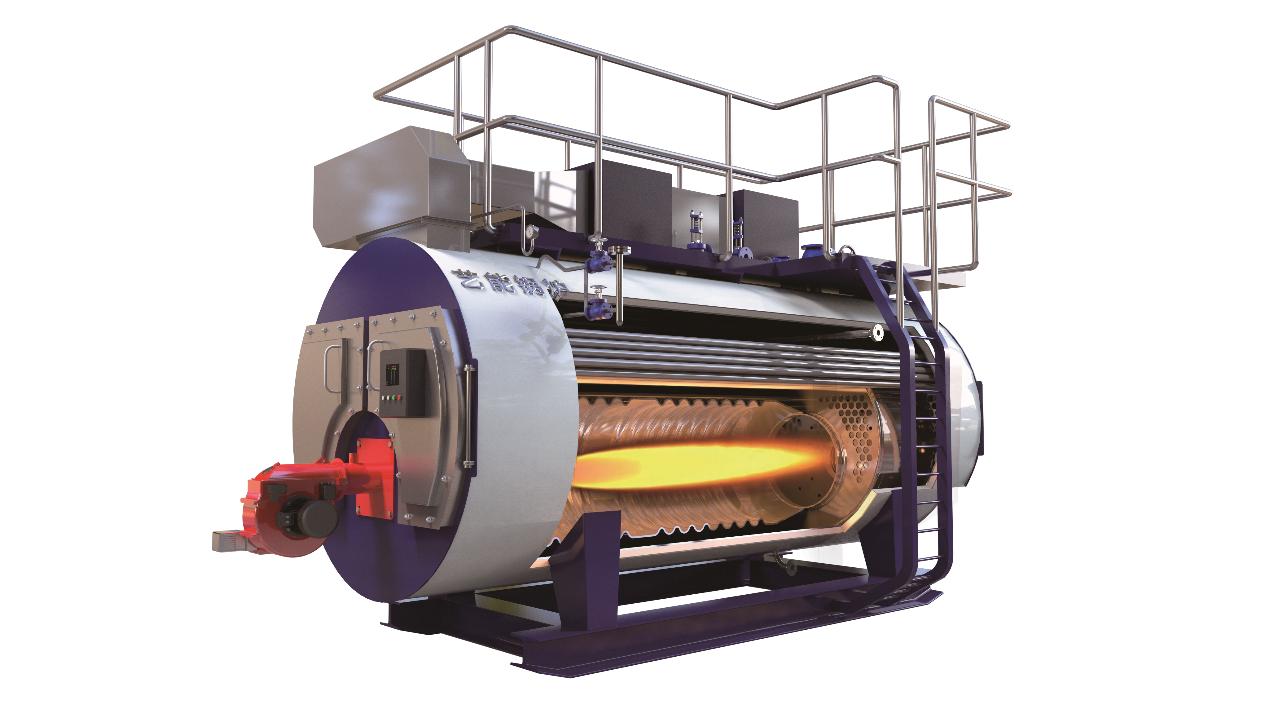

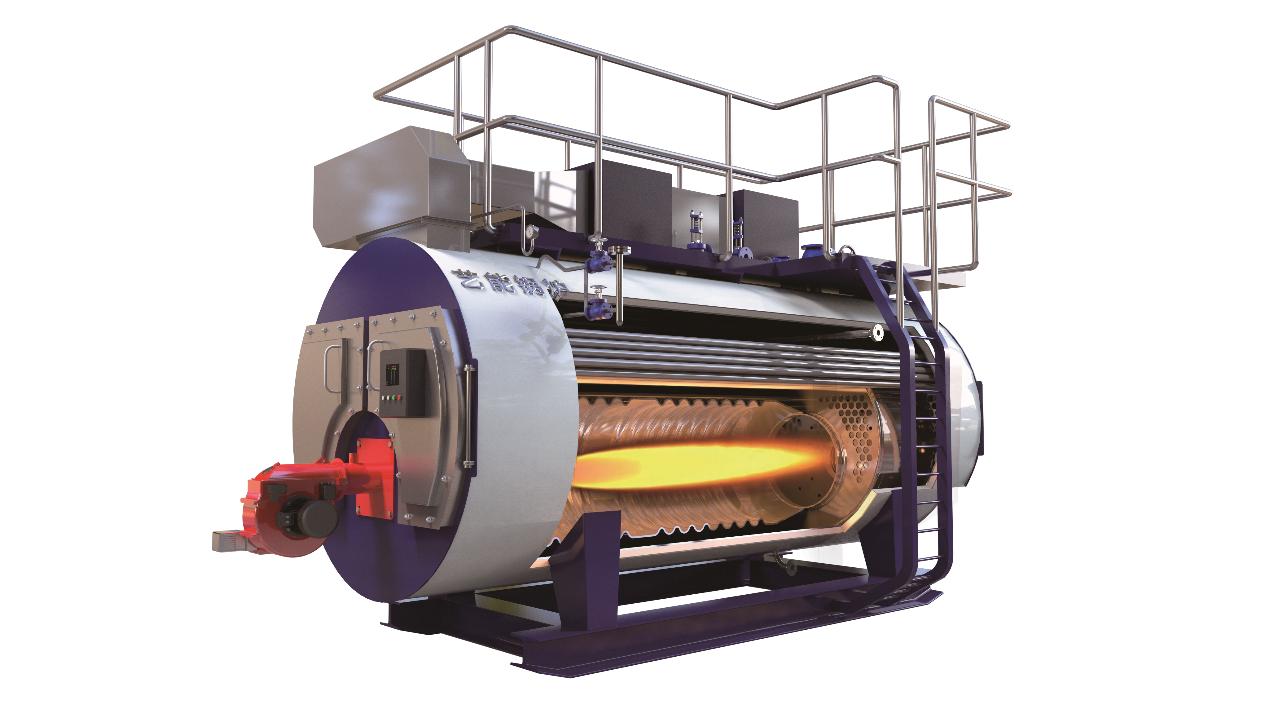

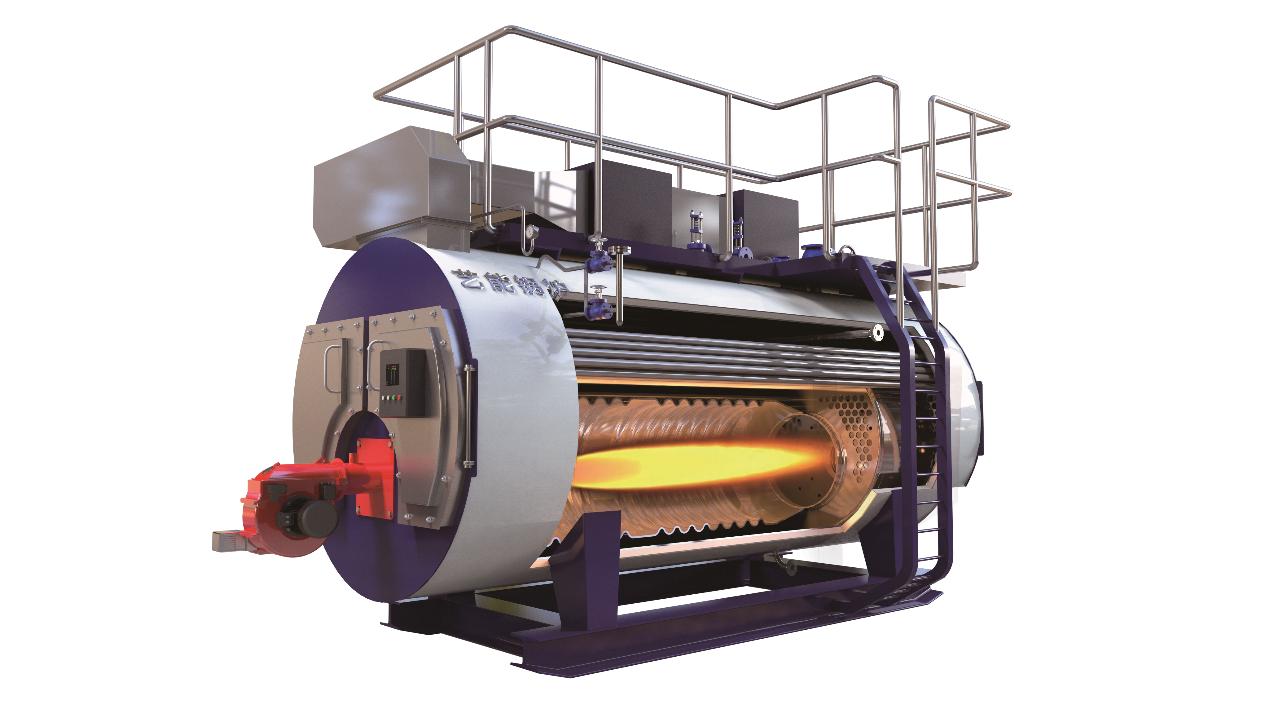

In the realm of industrial and residential heating systems, natural gas fired hot water boilers hold a significant position due to their efficiency and reliability. These appliances are manufactured in specialized factories that combine advanced technology with skilled craftsmanship to produce high-quality products. This article delves into the world of natural gas fired hot water boiler factories, exploring their operations, significance, and contribution to the global energy landscape.

Natural gas fired hot water boilers, as the name suggests, use natural gas as the primary fuel source to heat water for various applications. The efficiency of these boilers lies in their ability to convert the gas into heat with minimal waste, making them an eco-friendly alternative to traditional heating methods. They find extensive use in homes, commercial buildings, and even in power generation plants for their consistent performance and low operational costs.

The manufacturing process in a natural gas fired hot water boiler factory is a meticulous blend of engineering, design, and quality control. It begins with the fabrication of the boiler shell, often made from durable materials like steel or stainless steel, ensuring resistance to corrosion and high temperatures. Advanced welding techniques ensure airtight seals, preventing any gas leaks.

Next, the internal components such as burners, heat exchangers, and control systems are installed. Burners, which ignite the natural gas, are designed to optimize combustion efficiency. Heat exchangers, usually constructed from high-grade materials, efficiently transfer heat from the gas flame to the water. The control system ensures safe and precise operation, adjusting the gas flow and water temperature according to demand The control system ensures safe and precise operation, adjusting the gas flow and water temperature according to demand The control system ensures safe and precise operation, adjusting the gas flow and water temperature according to demand The control system ensures safe and precise operation, adjusting the gas flow and water temperature according to demand

The control system ensures safe and precise operation, adjusting the gas flow and water temperature according to demand The control system ensures safe and precise operation, adjusting the gas flow and water temperature according to demand natural gas fired hot water boiler factories.

Quality control is paramount in these factories. Each boiler undergoes rigorous testing, including pressure tests, leak checks, and operational simulations, to guarantee safety and efficiency. The finished products are then packaged and dispatched to distributors and end-users worldwide.

Natural gas fired hot water boiler factories not only contribute to the heating industry but also play a crucial role in the transition towards cleaner energy sources. As natural gas emits less carbon dioxide than coal or oil, these boilers help reduce greenhouse gas emissions. Moreover, they offer an efficient way to utilize the abundant natural gas reserves, enhancing energy security.

In conclusion, natural gas fired hot water boiler factories are integral to modern heating solutions. Their commitment to innovation, safety, and environmental responsibility is evident in the products they manufacture. These factories continue to evolve, embracing new technologies to enhance efficiency, minimize emissions, and cater to the ever-changing needs of consumers and industries. As the world moves towards cleaner and more sustainable energy options, the role of these factories in shaping the future of heating is undeniable.

natural gas fired hot water boiler factories.

Quality control is paramount in these factories. Each boiler undergoes rigorous testing, including pressure tests, leak checks, and operational simulations, to guarantee safety and efficiency. The finished products are then packaged and dispatched to distributors and end-users worldwide.

Natural gas fired hot water boiler factories not only contribute to the heating industry but also play a crucial role in the transition towards cleaner energy sources. As natural gas emits less carbon dioxide than coal or oil, these boilers help reduce greenhouse gas emissions. Moreover, they offer an efficient way to utilize the abundant natural gas reserves, enhancing energy security.

In conclusion, natural gas fired hot water boiler factories are integral to modern heating solutions. Their commitment to innovation, safety, and environmental responsibility is evident in the products they manufacture. These factories continue to evolve, embracing new technologies to enhance efficiency, minimize emissions, and cater to the ever-changing needs of consumers and industries. As the world moves towards cleaner and more sustainable energy options, the role of these factories in shaping the future of heating is undeniable.

The control system ensures safe and precise operation, adjusting the gas flow and water temperature according to demand The control system ensures safe and precise operation, adjusting the gas flow and water temperature according to demand

The control system ensures safe and precise operation, adjusting the gas flow and water temperature according to demand The control system ensures safe and precise operation, adjusting the gas flow and water temperature according to demand natural gas fired hot water boiler factories.

Quality control is paramount in these factories. Each boiler undergoes rigorous testing, including pressure tests, leak checks, and operational simulations, to guarantee safety and efficiency. The finished products are then packaged and dispatched to distributors and end-users worldwide.

Natural gas fired hot water boiler factories not only contribute to the heating industry but also play a crucial role in the transition towards cleaner energy sources. As natural gas emits less carbon dioxide than coal or oil, these boilers help reduce greenhouse gas emissions. Moreover, they offer an efficient way to utilize the abundant natural gas reserves, enhancing energy security.

In conclusion, natural gas fired hot water boiler factories are integral to modern heating solutions. Their commitment to innovation, safety, and environmental responsibility is evident in the products they manufacture. These factories continue to evolve, embracing new technologies to enhance efficiency, minimize emissions, and cater to the ever-changing needs of consumers and industries. As the world moves towards cleaner and more sustainable energy options, the role of these factories in shaping the future of heating is undeniable.

natural gas fired hot water boiler factories.

Quality control is paramount in these factories. Each boiler undergoes rigorous testing, including pressure tests, leak checks, and operational simulations, to guarantee safety and efficiency. The finished products are then packaged and dispatched to distributors and end-users worldwide.

Natural gas fired hot water boiler factories not only contribute to the heating industry but also play a crucial role in the transition towards cleaner energy sources. As natural gas emits less carbon dioxide than coal or oil, these boilers help reduce greenhouse gas emissions. Moreover, they offer an efficient way to utilize the abundant natural gas reserves, enhancing energy security.

In conclusion, natural gas fired hot water boiler factories are integral to modern heating solutions. Their commitment to innovation, safety, and environmental responsibility is evident in the products they manufacture. These factories continue to evolve, embracing new technologies to enhance efficiency, minimize emissions, and cater to the ever-changing needs of consumers and industries. As the world moves towards cleaner and more sustainable energy options, the role of these factories in shaping the future of heating is undeniable. Latest news

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.15,2025

-

Leading Electric Steam Boiler Manufacturers for IndustryNewsAug.14,2025

-

Buy Waste Heat Boilers: Custom, Efficient & Affordable SolutionsNewsAug.13,2025

-

Electric Steam Boiler Manufacturers | Industrial Power & EfficiencyNewsAug.12,2025

-

Electric Steam Boiler Manufacturers: Efficient & Reliable SolutionsNewsAug.11,2025

-

China Steam Boiler Price: Efficient Industrial Systems & BurnersNewsAug.10,2025