Jul . 08, 2024 02:10

Back to list

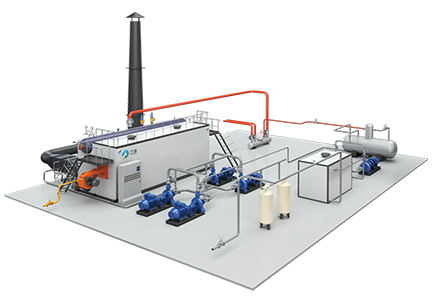

Factory specializing in manufacturing industrial hot water boilers for commercial and residential use.

An industrial hot water boiler factory is a place where large scale boilers are manufactured for various industries such as chemical, food processing, and energy production. These boilers are essential for providing hot water for heating processes, sterilization, cleaning, and other industrial applications.

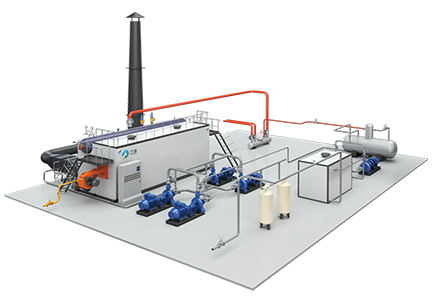

A typical industrial hot water boiler factory is equipped with advanced machinery and production lines to efficiently manufacture high-quality boilers. The factory is usually divided into different sections, each responsible for a specific stage of the production process. This includes boiler design, material sourcing, welding, fabrication, quality control, and testing.

The design team at the factory works closely with engineers to develop innovative and efficient boiler designs that meet the specific requirements of customers. They also ensure that the boilers comply with safety standards and regulations to guarantee the reliability and performance of the products.

The material sourcing department is responsible for procuring high-quality materials such as steel, copper, and other components needed for boiler manufacturing. They carefully select suppliers and conduct quality checks to ensure that only the best materials are used in the production process.

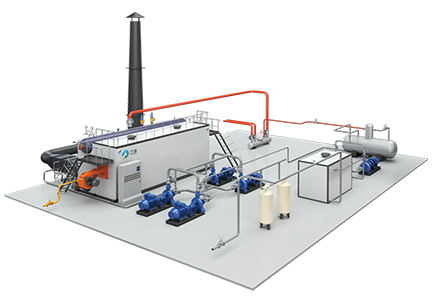

The welding and fabrication section of the factory plays a crucial role in assembling the components and welding them together to create the final boiler structure. Skilled welders use advanced welding techniques to ensure the strength and durability of the boilers, while fabricators work to polish and finish the boilers to meet aesthetic and functional requirements Skilled welders use advanced welding techniques to ensure the strength and durability of the boilers, while fabricators work to polish and finish the boilers to meet aesthetic and functional requirements Skilled welders use advanced welding techniques to ensure the strength and durability of the boilers, while fabricators work to polish and finish the boilers to meet aesthetic and functional requirements Skilled welders use advanced welding techniques to ensure the strength and durability of the boilers, while fabricators work to polish and finish the boilers to meet aesthetic and functional requirements

Skilled welders use advanced welding techniques to ensure the strength and durability of the boilers, while fabricators work to polish and finish the boilers to meet aesthetic and functional requirements Skilled welders use advanced welding techniques to ensure the strength and durability of the boilers, while fabricators work to polish and finish the boilers to meet aesthetic and functional requirements industrial hot water boiler factory.

Quality control is a key aspect of the production process at an industrial hot water boiler factory. Inspectors closely monitor each stage of production to check for defects, quality issues, and deviations from the design specifications. This ensures that only high-quality boilers are produced and delivered to customers.

Before the boilers are shipped out, they undergo rigorous testing to ensure that they meet performance standards and safety requirements. This includes pressure testing, leak testing, and functional testing to verify that the boilers operate efficiently and reliably.

Overall, an industrial hot water boiler factory plays a vital role in supplying the industry with essential heating equipment. By utilizing advanced technology, skilled labor, and strict quality control measures, these factories are able to produce top-quality boilers that meet the diverse needs of industrial customers. With a focus on innovation and excellence, industrial hot water boiler factories continue to drive the industry forward and support the growth and development of various sectors that rely on hot water boilers for their operations.

industrial hot water boiler factory.

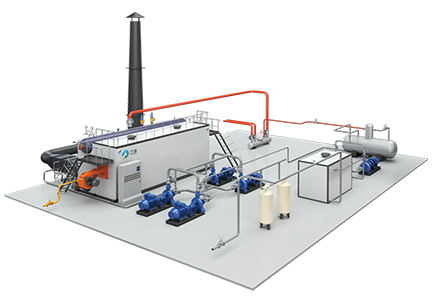

Quality control is a key aspect of the production process at an industrial hot water boiler factory. Inspectors closely monitor each stage of production to check for defects, quality issues, and deviations from the design specifications. This ensures that only high-quality boilers are produced and delivered to customers.

Before the boilers are shipped out, they undergo rigorous testing to ensure that they meet performance standards and safety requirements. This includes pressure testing, leak testing, and functional testing to verify that the boilers operate efficiently and reliably.

Overall, an industrial hot water boiler factory plays a vital role in supplying the industry with essential heating equipment. By utilizing advanced technology, skilled labor, and strict quality control measures, these factories are able to produce top-quality boilers that meet the diverse needs of industrial customers. With a focus on innovation and excellence, industrial hot water boiler factories continue to drive the industry forward and support the growth and development of various sectors that rely on hot water boilers for their operations.

Skilled welders use advanced welding techniques to ensure the strength and durability of the boilers, while fabricators work to polish and finish the boilers to meet aesthetic and functional requirements Skilled welders use advanced welding techniques to ensure the strength and durability of the boilers, while fabricators work to polish and finish the boilers to meet aesthetic and functional requirements

Skilled welders use advanced welding techniques to ensure the strength and durability of the boilers, while fabricators work to polish and finish the boilers to meet aesthetic and functional requirements Skilled welders use advanced welding techniques to ensure the strength and durability of the boilers, while fabricators work to polish and finish the boilers to meet aesthetic and functional requirements industrial hot water boiler factory.

Quality control is a key aspect of the production process at an industrial hot water boiler factory. Inspectors closely monitor each stage of production to check for defects, quality issues, and deviations from the design specifications. This ensures that only high-quality boilers are produced and delivered to customers.

Before the boilers are shipped out, they undergo rigorous testing to ensure that they meet performance standards and safety requirements. This includes pressure testing, leak testing, and functional testing to verify that the boilers operate efficiently and reliably.

Overall, an industrial hot water boiler factory plays a vital role in supplying the industry with essential heating equipment. By utilizing advanced technology, skilled labor, and strict quality control measures, these factories are able to produce top-quality boilers that meet the diverse needs of industrial customers. With a focus on innovation and excellence, industrial hot water boiler factories continue to drive the industry forward and support the growth and development of various sectors that rely on hot water boilers for their operations.

industrial hot water boiler factory.

Quality control is a key aspect of the production process at an industrial hot water boiler factory. Inspectors closely monitor each stage of production to check for defects, quality issues, and deviations from the design specifications. This ensures that only high-quality boilers are produced and delivered to customers.

Before the boilers are shipped out, they undergo rigorous testing to ensure that they meet performance standards and safety requirements. This includes pressure testing, leak testing, and functional testing to verify that the boilers operate efficiently and reliably.

Overall, an industrial hot water boiler factory plays a vital role in supplying the industry with essential heating equipment. By utilizing advanced technology, skilled labor, and strict quality control measures, these factories are able to produce top-quality boilers that meet the diverse needs of industrial customers. With a focus on innovation and excellence, industrial hot water boiler factories continue to drive the industry forward and support the growth and development of various sectors that rely on hot water boilers for their operations. Latest news

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025