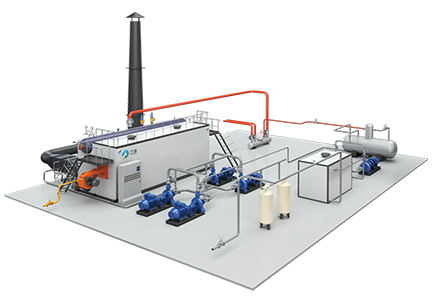

famous hot oil circulating system

The Benefits of a Famous Hot Oil Circulating System

In the world of industrial applications, the efficiency and reliability of heat transfer systems are paramount. One such system that has gained fame for its effectiveness is the hot oil circulating system. Often employed in various industries, including food processing, petrochemical, and manufacturing, hot oil circulating systems offer a range of advantages that make them a preferred choice for many applications.

What is a Hot Oil Circulating System?

At its core, a hot oil circulating system is designed to transfer heat from one area to another using thermal oil. Unlike water-based systems, thermal oil can operate at higher temperatures without the risk of boiling. This allows for the effective transfer of heat across extensive distances without excessive energy loss, making it suitable for processes where consistent and precise temperature control is required.

Key Components

A typical hot oil circulating system includes several essential components. These typically consist of

1. Thermal Oil Heater The heart of the system, this component heats the oil to the desired temperature. 2. Circulation Pump Responsible for moving the heated oil through the system, ensuring that it reaches all necessary components effectively. 3. Heat Exchangers These are used to transfer heat from the oil to the process fluid without mixing them, maintaining hygiene and safety. 4. Expansion Tank This helps to accommodate the thermal expansion of the oil as it heats up, ensuring system pressure remains stable.

Advantages of Hot Oil Circulating Systems

1. High Temperature Capability One of the primary advantages of hot oil systems is their ability to operate at significantly higher temperatures compared to water-based systems. This is crucial for many industrial processes, such as drying, baking, or chemical reactions, where elevated temperatures are necessary.

famous hot oil circulating system

2. Energy Efficiency Hot oil systems are highly efficient due to their design. The thermal oil retains heat for a longer time, reducing the energy required to maintain the set temperatures. This means lower energy costs and a reduced carbon footprint, contributing to a more sustainable operation.

3. Consistent Temperature Control The precision offered by hot oil systems ensures that temperatures remain consistent throughout the process. This is particularly important in applications such as food processing, where even small fluctuations in temperature can impact product quality.

4. Corrosion Resistance Thermal oils are typically formulated to resist oxidation and corrosion. This longevity in oil performance means reduced maintenance costs and less frequent oil replacements, leading to lower overall operational expenses.

5. Versatility Hot oil circulating systems can be used across various industries, from food and beverage to pharmaceuticals and petrochemicals. This versatility makes them an attractive option for manufacturers looking to invest in a singular but adaptable heating solution.

Applications in Various Industries

The applications for hot oil circulating systems are vast. In the food industry, they are used in processes such as frying, cooking, and confectionery production, where precise and uniform heating is crucial. In the petrochemical sector, these systems play a vital role in the distillation process and the processing of various chemicals that require stringent temperature control.

Moreover, manufacturing operations often deploy hot oil heating systems for processes such as mold heating and thermal fluid systems. The ability to maintain high temperatures without the risk of boiling water makes these systems essential in settings that require both efficiency and safety.

Conclusion

The hot oil circulating system stands as a testament to the ingenuity of industrial heating solutions. Its ability to provide high temperature capabilities, energy efficiency, and consistent temperature control, combined with its versatility across various sectors, makes it a highly valuable asset for any industry that relies on intricate heating processes. As industries continue to evolve and seek more efficient and reliable solutions, the hot oil circulating system will undoubtedly remain a significant player in the world of industrial heat transfer.

-

Leading Electric Steam Boiler Manufacturers & Industrial SolutionsNewsAug.09,2025

-

Industrial Electric Steam Boiler Manufacturers | Efficient SolutionsNewsAug.08,2025

-

Industrial Electric Steam Boilers | Top Manufacturers & SuppliersNewsAug.07,2025

-

Leading Electric Steam Boiler Manufacturers for IndustryNewsAug.06,2025

-

Top Electric Steam Boiler Manufacturers | AI EfficiencyNewsAug.04,2025

-

Efficient Thermal Oil Boilers with AI Optimization | Superior PerformanceNewsAug.03,2025