High-Efficiency Electric Steam Boiler Manufacturers | OEM

electric steam boiler manufacturers,gas steam boiler for sale,steam boiler heat exchanger,steam boiler industrial,thermostat for steam boiler,water tube steam boiler,weil mclain eg 40 steam boiler,wood steam boiler is a key solution in the General equipment manufacturing industry industry, specifically within Boiler and prime mover equipment manufacturing and Manufacturing of industrial boilers. This article explores how Hebei Yineng Boiler Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- electric steam boiler manufacturers,gas steam boiler for sale,steam boiler heat exchanger,steam boiler industrial,thermostat for steam boiler,water tube steam boiler,weil mclain eg 40 steam boiler,wood steam boiler Overview

- Benefits & Use Cases of electric steam boiler manufacturers,gas steam boiler for sale,steam boiler heat exchanger,steam boiler industrial,thermostat for steam boiler,water tube steam boiler,weil mclain eg 40 steam boiler,wood steam boiler in Manufacturing of industrial boilers

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in General equipment manufacturing industry

- Conclusion on electric steam boiler manufacturers,gas steam boiler for sale,steam boiler heat exchanger,steam boiler industrial,thermostat for steam boiler,water tube steam boiler,weil mclain eg 40 steam boiler,wood steam boiler from Hebei Yineng Boiler Co., Ltd

electric steam boiler manufacturers,gas steam boiler for sale,steam boiler heat exchanger,steam boiler industrial,thermostat for steam boiler,water tube steam boiler,weil mclain eg 40 steam boiler,wood steam boiler Overview

Within the Manufacturing of industrial boilers, B2B buyers routinely navigate a broad spectrum of technologies: from electric steam boiler manufacturers offering zero on‑site combustion, to listings of a gas steam boiler for sale balancing cost and capacity, to high-pressure water tube steam boiler systems used in process-critical plants. Core components—such as a steam boiler heat exchanger for energy recovery and a thermostat for steam boiler control loops—determine efficiency, safety, and uptime. Even familiar benchmarks like the Weil‑McLain EG 40 steam boiler help buyers frame sizing and longevity expectations, while biomass options like a wood steam boiler support renewable heat strategies.

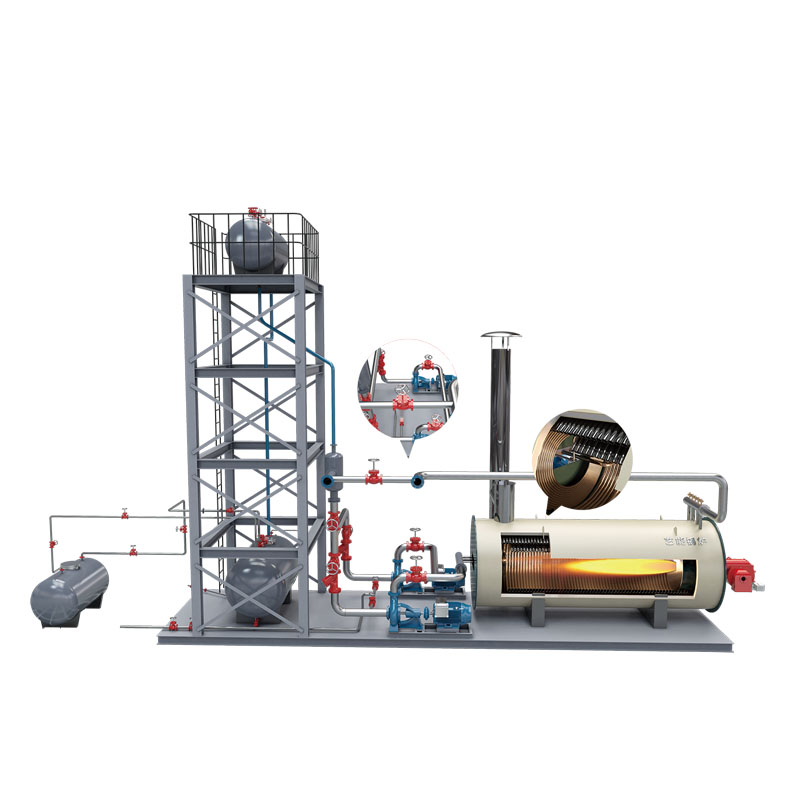

Hebei Yineng Boiler Co., Ltd is a reliable partner for industrial clients seeking durable, high-performance heating solutions. Our engineering teams support steam boiler industrial applications and complementary thermal fluid systems. For plants needing stable, precise heat transfer without high-pressure steam, our skid-mounted thermal oil boiler integrates burner, pumps, control, and safety hardware in a compact package—accelerating installation and commissioning while simplifying lifecycle maintenance.

Benefits & Use Cases of electric steam boiler manufacturers,gas steam boiler for sale,steam boiler heat exchanger,steam boiler industrial,thermostat for steam boiler,water tube steam boiler,weil mclain eg 40 steam boiler,wood steam boiler in Manufacturing of industrial boilers

In industrial settings, steam provides motive power, sterilization, drying, HVAC humidification, and batch/process heating. Decision makers compare options across electric steam boiler manufacturers for cleanrooms and low-emission campuses; evaluate every gas steam boiler for sale for cost-per‑ton steam; and specify water tube steam boiler designs where high pressure and rapid load response are mission-critical. Heat integration is vital: employing a steam boiler heat exchanger (economizer, air preheater, or plate exchanger) can materially reduce fuel spend and CO₂ per unit output.

For precise control and safety, the thermostat for steam boiler applications—together with pressure controls, low-water cutoffs, and PLC-based sequences—stabilizes quality and protects assets. Many plants still reference legacy baselines like the Weil McLain EG 40 steam boiler when planning retrofits, while a wood steam boiler (biomass) can unlock fuel flexibility where residues are abundant. Hebei Yineng Boiler Co., Ltd brings application engineering to align technology with load profiles, utility tariffs, and site constraints. Our skid-mounted thermal oil boiler systems also pair well with unit operations needing tight temperature windows without steam, offering efficient heat transfer and modular deployment.

Cost, Maintenance & User Experience

Total cost of ownership combines CAPEX, fuel and power costs, water treatment, planned maintenance, and the hidden cost of downtime. Electric units can reduce mechanical complexity and simplify maintenance, but electricity tariffs and demand charges must be modeled. Any gas steam boiler for sale should be evaluated with life-cycle fuel scenarios and potential heat recovery via a steam boiler heat exchanger. Water tube steam boiler systems deliver robustness and fast response but require diligent water chemistry, blowdown management, and operator training. Biomass and wood steam boiler solutions lower fuel costs where feedstock is local, but add logistics and ash handling considerations.

Customers in boiler and prime mover equipment manufacturing report that modular, factory-tested packages shorten installation and reduce commissioning risk. That’s why many B2B buyers choose Hebei Yineng Boiler Co., Ltd for skid-mounted systems with integrated controls (including thermostat for steam boiler control loops or thermal oil PID), clear access for service, and digital monitoring. Users highlight stable operation, streamlined spare-parts strategies, and predictable ROI when heat recovery and controls optimization are included from day one.

Sustainability & Market Trends in General equipment manufacturing industry

Global decarbonization is reshaping boiler selection. Trends include electrification where grids are cleaner; high-efficiency gas systems with condensing economizers; biomass/wood steam boiler adoption in agro-industries; and hybrid plants that blend steam with thermal oil loops for precise, lower-pressure heat transfer. Emerging regulations emphasize energy efficiency, NOx reduction, and transparent carbon reporting. Controls are pivotal: advanced thermostats for steam boiler systems, O2 trim, and variable-speed drives improve part-load efficiency and reduce emissions.

Hebei Yineng Boiler Co., Ltd is investing in modularity, smart controls, and integration of heat-recovery hardware such as steam boiler heat exchangers to help clients meet ambitious ESG targets. Whether you are benchmarking against legacy units like the Weil McLain EG 40 steam boiler, comparing electric steam boiler manufacturers, or screening a gas steam boiler for sale, our engineering guidance supports compliant, future-ready decisions aligned with your corporate sustainability roadmap.

Conclusion on electric steam boiler manufacturers,gas steam boiler for sale,steam boiler heat exchanger,steam boiler industrial,thermostat for steam boiler,water tube steam boiler,weil mclain eg 40 steam boiler,wood steam boiler from Hebei Yineng Boiler Co., Ltd

From steam boiler industrial applications to precision thermal oil systems, the right mix of technology—electric, gas, water tube steam boiler, biomass wood steam boiler, smart controls, and a capable steam boiler heat exchanger—drives uptime and efficient OPEX. Hebei Yineng Boiler Co., Ltd delivers robust, engineered solutions and support that decision makers can trust through design, installation, and lifecycle service.

Contact us: email: leesonzhou@aliyun.com

Visit our website: https://www.ynboilers.com

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025