Feb . 13, 2025 19:35

Back to list

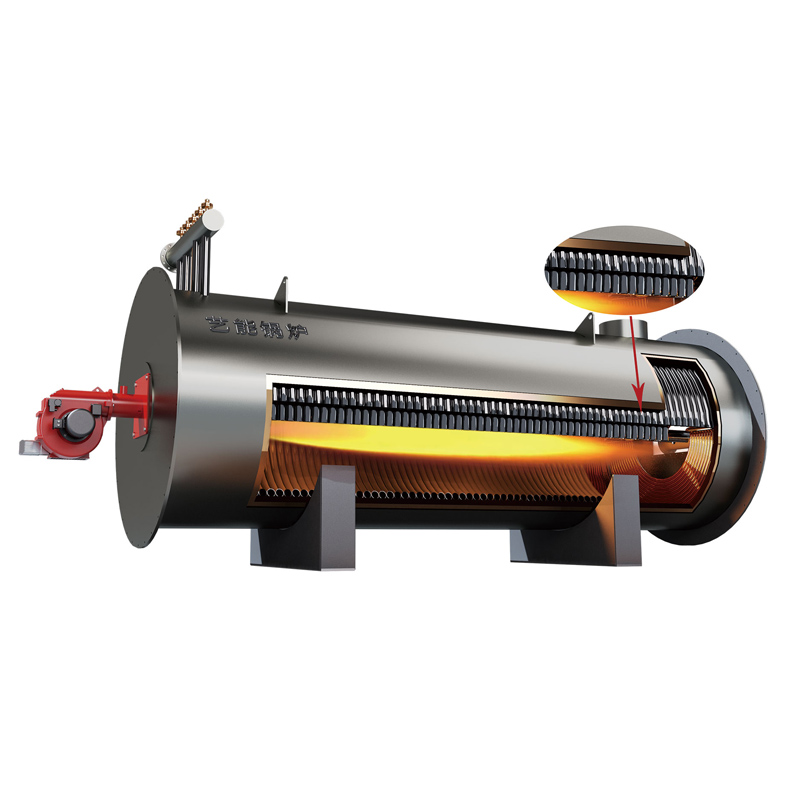

Coal fired SZL double drum water tube chain grate steam boiler

Choosing the right boiler for chemical fiber manufacturing is crucial to optimizing production efficiency and ensuring high product quality. Chemical fiber production involves various complex processes like polymer melting, fiber spinning, and drawing, which require precise temperature control. Therefore, incorporating a high-quality boiler system is indispensable for maintaining continuity and quality throughout these stages.

From an authoritative perspective, it's essential to rely on industry standards and certifications when evaluating boiler systems. Accredited manufacturers who comply with international standards such as ASME (American Society of Mechanical Engineers) or ISO (International Organization for Standardization) provide the assurance of quality and reliability. Such certifications indicate that a boiler has passed rigorous testing and meets high safety and performance criteria, which is critical when operating in industries with stringent regulatory requirements. Leveraging the expertise of certified manufacturers can thus provide added reliability and peace of mind. Trustworthiness in a boiler system is reflected in the vendor’s reputation and customer testimonials. Engaging with manufacturers known for their innovation, support, and after-sales service is crucial. Reliable vendors will offer comprehensive maintenance plans and timely technical support, ensuring that your boiler operates smoothly with minimal downtime. Case studies showcasing successful implementations in similar manufacturing settings can serve as a valuable indicator of a vendor's reliability and the boiler system's adaptability and performance in chemical fiber production. Ultimately, investing in a high-quality boiler optimized for chemical fiber production not only boosts operational efficiency but also enhances product quality. By prioritizing experience, expertise, authoritativeness, and trustworthiness in your selection process, you can ensure that your manufacturing plant is equipped with a robust and efficient boiler system that meets both current and future demands. This strategic investment lays the foundation for consistent high-quality fiber production, energy efficiency, and economic sustainability, positioning your company as a leader in the competitive chemical fiber industry.

From an authoritative perspective, it's essential to rely on industry standards and certifications when evaluating boiler systems. Accredited manufacturers who comply with international standards such as ASME (American Society of Mechanical Engineers) or ISO (International Organization for Standardization) provide the assurance of quality and reliability. Such certifications indicate that a boiler has passed rigorous testing and meets high safety and performance criteria, which is critical when operating in industries with stringent regulatory requirements. Leveraging the expertise of certified manufacturers can thus provide added reliability and peace of mind. Trustworthiness in a boiler system is reflected in the vendor’s reputation and customer testimonials. Engaging with manufacturers known for their innovation, support, and after-sales service is crucial. Reliable vendors will offer comprehensive maintenance plans and timely technical support, ensuring that your boiler operates smoothly with minimal downtime. Case studies showcasing successful implementations in similar manufacturing settings can serve as a valuable indicator of a vendor's reliability and the boiler system's adaptability and performance in chemical fiber production. Ultimately, investing in a high-quality boiler optimized for chemical fiber production not only boosts operational efficiency but also enhances product quality. By prioritizing experience, expertise, authoritativeness, and trustworthiness in your selection process, you can ensure that your manufacturing plant is equipped with a robust and efficient boiler system that meets both current and future demands. This strategic investment lays the foundation for consistent high-quality fiber production, energy efficiency, and economic sustainability, positioning your company as a leader in the competitive chemical fiber industry.

Latest news

-

China Steam Boiler Price: Efficient Industrial Systems & BurnersNewsAug.10,2025

-

Leading Electric Steam Boiler Manufacturers & Industrial SolutionsNewsAug.09,2025

-

Industrial Electric Steam Boiler Manufacturers | Efficient SolutionsNewsAug.08,2025

-

Industrial Electric Steam Boilers | Top Manufacturers & SuppliersNewsAug.07,2025

-

Leading Electric Steam Boiler Manufacturers for IndustryNewsAug.06,2025

-

Top Electric Steam Boiler Manufacturers | AI EfficiencyNewsAug.04,2025