Feb . 18, 2025 01:09

Back to list

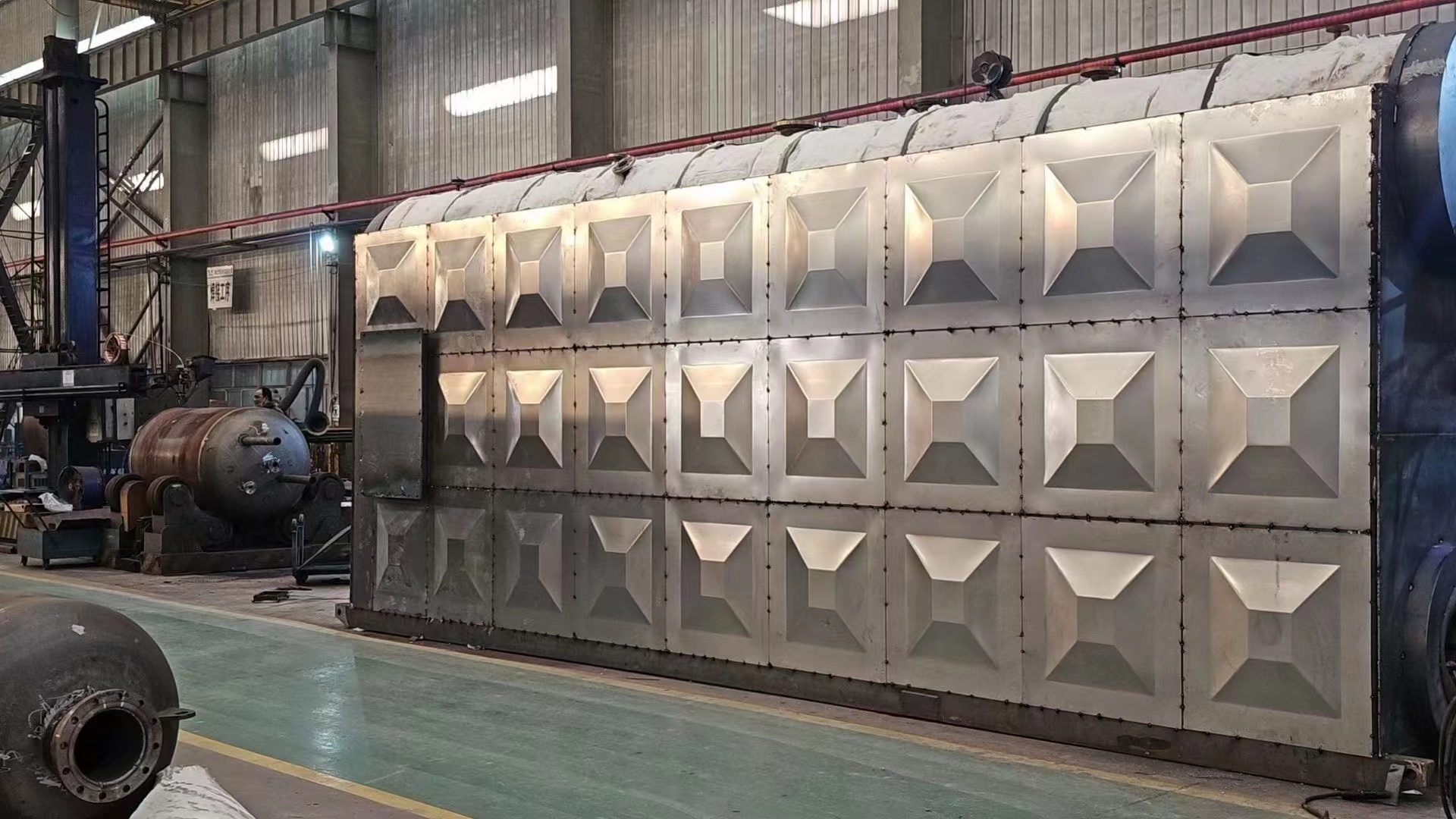

Coal fired SZL double drum water tube chain grate steam boiler

Achieving optimal efficiency and reliability from a high quality power plant steam boiler requires an understanding of both the technical specifications and the operational expertise behind these complex systems. As one of the most crucial components in power generation, steam boilers must be designed and maintained with the utmost care to ensure they deliver consistent performance and safety.

Trustworthiness in the context of high-quality power plant steam boilers means adhering to rigorous certifications and compliance with international standards. The performance claims need to be backed by independent testing or third-party verification to build confidence among industry stakeholders. Moreover, a dependable manufacturer offers comprehensive after-sales services, including maintenance and technical support, ensuring prolonged system integrity and performance. Integrating the latest technology, modern high-quality steam boilers now feature automated controls and data analytics capabilities to optimize operation. Such technological advancements allow operators to monitor performance in real-time, adjust parameters for enhanced efficiency, and preemptively address potential issues before they escalate. The incorporation of Artificial Intelligence (AI) and Internet of Things (IoT) has further revolutionized how these systems are managed, offering predictive maintenance solutions that save cost and improve uptime. Energy efficiency is paramount in the design and operation of steam boilers for power plants. The implementation of innovative thermal management systems helps extract maximum energy from every unit of fuel consumed. Condensing boilers, for example, reclaim latent heat and recycle it back into the process, thereby significantly increasing thermal efficiency. Finally, sustainability is becoming increasingly important in the design of modern steam boilers. Manufacturers are exploring eco-friendly options such as biomass-fired boilers and those compatible with renewable energy sources. By reducing carbon footprints and adhering to stricter environmental regulations, these systems align with global goals for cleaner energy production. In conclusion, choosing a high-quality power plant steam boiler is an investment in reliability, efficiency, and sustainability. Professionals in this field are committed to delivering systems that not only meet current performance standards but also anticipate future challenges and opportunities in power generation. With the right combination of experience, expertise, authoritativeness, and trustworthiness, top-tier steam boiler manufacturers provide invaluable contributions to industries worldwide, ensuring their systems remain at the cutting-edge of technological advancements.

Trustworthiness in the context of high-quality power plant steam boilers means adhering to rigorous certifications and compliance with international standards. The performance claims need to be backed by independent testing or third-party verification to build confidence among industry stakeholders. Moreover, a dependable manufacturer offers comprehensive after-sales services, including maintenance and technical support, ensuring prolonged system integrity and performance. Integrating the latest technology, modern high-quality steam boilers now feature automated controls and data analytics capabilities to optimize operation. Such technological advancements allow operators to monitor performance in real-time, adjust parameters for enhanced efficiency, and preemptively address potential issues before they escalate. The incorporation of Artificial Intelligence (AI) and Internet of Things (IoT) has further revolutionized how these systems are managed, offering predictive maintenance solutions that save cost and improve uptime. Energy efficiency is paramount in the design and operation of steam boilers for power plants. The implementation of innovative thermal management systems helps extract maximum energy from every unit of fuel consumed. Condensing boilers, for example, reclaim latent heat and recycle it back into the process, thereby significantly increasing thermal efficiency. Finally, sustainability is becoming increasingly important in the design of modern steam boilers. Manufacturers are exploring eco-friendly options such as biomass-fired boilers and those compatible with renewable energy sources. By reducing carbon footprints and adhering to stricter environmental regulations, these systems align with global goals for cleaner energy production. In conclusion, choosing a high-quality power plant steam boiler is an investment in reliability, efficiency, and sustainability. Professionals in this field are committed to delivering systems that not only meet current performance standards but also anticipate future challenges and opportunities in power generation. With the right combination of experience, expertise, authoritativeness, and trustworthiness, top-tier steam boiler manufacturers provide invaluable contributions to industries worldwide, ensuring their systems remain at the cutting-edge of technological advancements.

Latest news

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025

-

High-Efficiency Thermal Oil Boiler for Industrial Heating SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers for Industrial EfficiencyNewsJul.28,2025

-

Top Electric Steam Boiler Manufacturers | Industrial Solutions & CustomizationNewsJul.27,2025