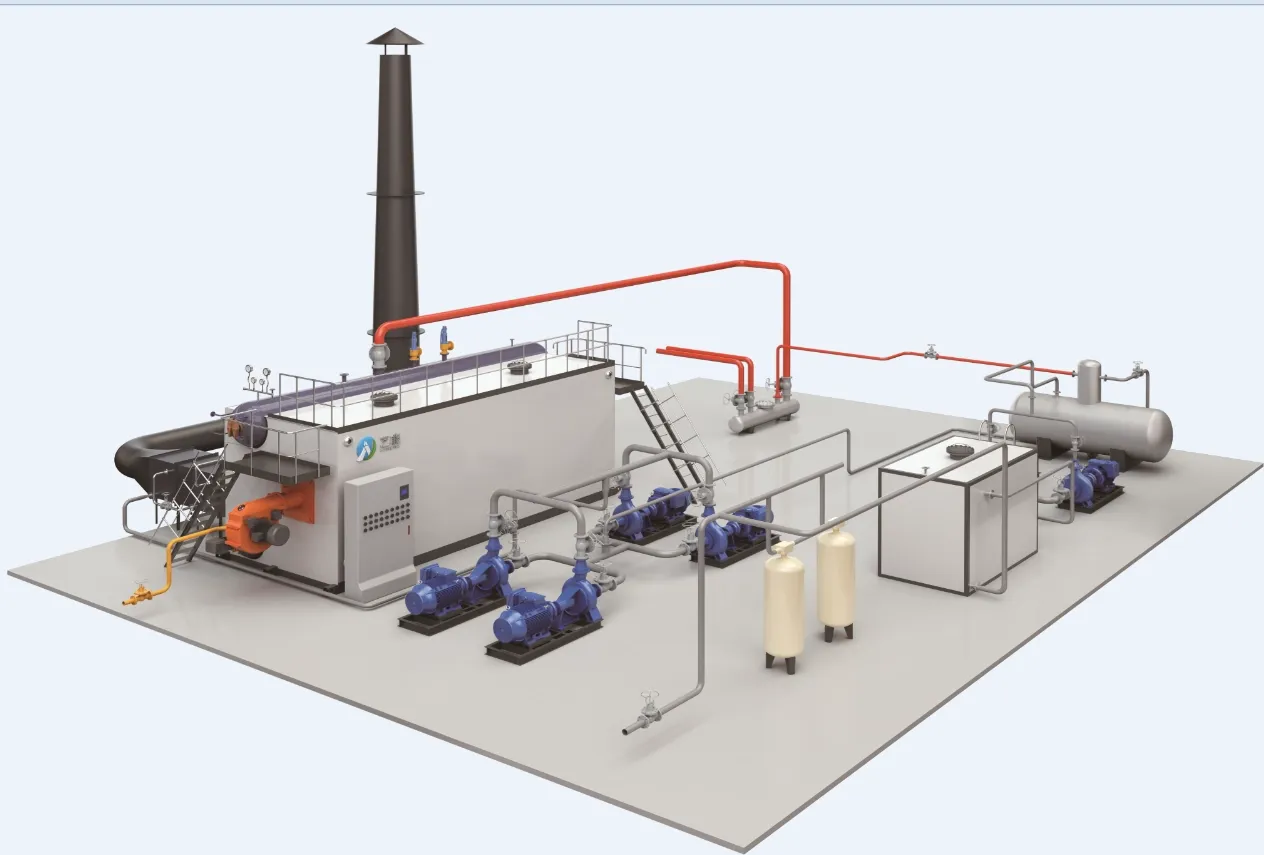

high quality steam boiler heat exchanger

High-Quality Steam Boiler Heat Exchangers An Overview

In today's industrial landscape, the efficient transfer of heat is paramount to maintaining optimal operational procedures and ensuring energy efficiency. Steam boiler heat exchangers play a crucial role in various sectors, including power generation, chemical processing, and manufacturing. This article delves into the significance, functionality, and benefits of high-quality steam boiler heat exchangers.

Understanding Steam Boiler Heat Exchangers

At its core, a heat exchanger is a device designed to transfer heat between two or more fluids without allowing them to mix. In the context of steam boilers, these devices utilize the thermal energy generated by steam to heat other fluids, such as water or air, thereby enhancing energy efficiency and operational effectiveness.

Steam boiler heat exchangers come in various configurations, including shell and tube, plate, and finned tube designs. Each type offers distinct advantages depending on the specific application and operational requirements. However, what truly separates high-quality heat exchangers from ordinary ones is the materials used, design precision, and overall construction quality.

The Importance of High Quality

Quality in heat exchangers is vital for several reasons

1. Efficiency High-quality heat exchangers facilitate superior thermal transfer. This means more effective heating or cooling with less energy consumption, contributing to reduced operational costs.

2. Durability Industrial processes often expose heat exchangers to extreme conditions. High-quality materials, such as stainless steel and specialized alloys, enhance the durability and longevity of these devices, reducing the frequency of replacements and maintenance.

3. Safety Steam boilers operate under high pressure and temperature. A reliable heat exchanger minimizes the risk of leaks and failures, ensuring safe operations and compliance with industry regulations.

4. Performance A well-designed heat exchanger can significantly enhance the overall performance of a boiler system. High-quality models are engineered to optimize flow rates and minimize pressure drops, providing consistent performance even under varying operational conditions.

high quality steam boiler heat exchanger

Key Features of High-Quality Heat Exchangers

When evaluating steam boiler heat exchangers, several features indicate their quality and performance potential

- Thermal Conductivity High-quality heat exchangers boast materials with high thermal conductivity, maximizing heat transfer efficiency.

- Corrosion Resistance Industrial environments can be corrosive. Heat exchangers constructed from corrosion-resistant materials extend lifespan and reduce the risk of failure.

- Design Flexibility High-quality heat exchangers offer customization options to meet specific process requirements, which can be critical for unique industrial applications.

- Maintenance Accessibility Easy access for cleaning and maintenance is vital for ensuring the longevity and reliability of the heat exchanger. Designs that facilitate routine inspections and servicing can significantly reduce downtime.

Conclusion

In conclusion, high-quality steam boiler heat exchangers are essential components in achieving efficient and safe thermal energy transfer in various industrial applications. Their role in enhancing efficiency, durability, and safety cannot be overstated. As industries continue to push for more sustainable and efficient operations, investing in high-quality heat exchangers emerges as a strategic choice that pays off in the long run.

Choosing the right heat exchanger involves considering not just initial costs but also long-term benefits. Operators must prioritize quality to ensure their systems operate efficiently and reliably. As manufacturers continue to innovate and improve designs, the future of steam boiler heat exchangers looks promising, paving the way for enhanced productivity and sustainability in industrial processes.

By focusing on high quality, businesses can not only achieve their heating and cooling objectives but also contribute to a more energy-efficient future.

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025

-

High-Efficiency Thermal Oil Boiler for Industrial Heating SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers for Industrial EfficiencyNewsJul.28,2025

-

Top Electric Steam Boiler Manufacturers | Industrial Solutions & CustomizationNewsJul.27,2025