Feb . 13, 2025 06:05

Back to list

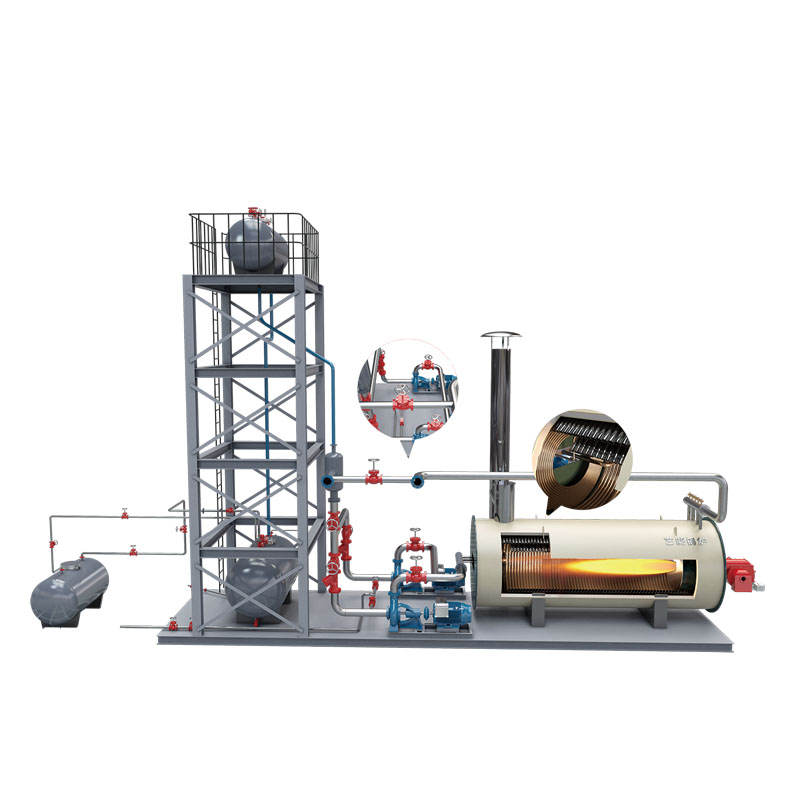

Horizontal/Vertical type YQW/L gas or diesel oil fired thermal oil boiler heater

In industrial settings where precision, reliability, and energy efficiency are paramount, vertical thermal oil heaters emerge as a quintessential component. These heaters are cherished not only for their exceptional performance but also for their role in optimising operational processes.

Vertical thermal oil heaters also boast a high level of environmental consideration. By optimising the combustion process, these systems can achieve reduced emissions, aligning with modern ecological mandates. Many industries are able to transition towards greener operations without compromising on performance due to these innovations. In addition, the use of thermal oil as a heat carrier eliminates the risk of corrosion, a common issue in steam-based systems, ensuring a sustainable and long-term operational lifecycle. Selecting a high-quality vertical thermal oil heater involves assessing specific operational needs and consulting with manufacturers who possess authoritative expertise in thermal management systems. These professionals guide businesses in choosing and customising heaters with appropriate capacity, efficiency ratings, and controls suited to unique industrial conditions. This collaborative approach not only ensures the acquisition of a product tailored to individual specifications but also augments overall trustworthiness in the provider’s solutions. Companies investing in these heaters are assured of a return on investment through reduced maintenance costs and enhanced energy efficiency. The durability and low operational failure rates, accredited to the meticulous design and material integrity, further corroborate the financial viability of opting for high-quality vertical thermal oil heaters. In closing, vertical thermal oil heaters stand as a testament to engineering progress, marrying efficiency with sustainability. As industry demands evolve, these heaters remain indispensable, offering cutting-edge solutions that harmonise with the pressing needs for economical and eco-friendly industrial processes. The narrative of their excellence will continue to shape sectors looking to optimise thermal management technologies, cementing their place as a cornerstone in industrial innovation.

Vertical thermal oil heaters also boast a high level of environmental consideration. By optimising the combustion process, these systems can achieve reduced emissions, aligning with modern ecological mandates. Many industries are able to transition towards greener operations without compromising on performance due to these innovations. In addition, the use of thermal oil as a heat carrier eliminates the risk of corrosion, a common issue in steam-based systems, ensuring a sustainable and long-term operational lifecycle. Selecting a high-quality vertical thermal oil heater involves assessing specific operational needs and consulting with manufacturers who possess authoritative expertise in thermal management systems. These professionals guide businesses in choosing and customising heaters with appropriate capacity, efficiency ratings, and controls suited to unique industrial conditions. This collaborative approach not only ensures the acquisition of a product tailored to individual specifications but also augments overall trustworthiness in the provider’s solutions. Companies investing in these heaters are assured of a return on investment through reduced maintenance costs and enhanced energy efficiency. The durability and low operational failure rates, accredited to the meticulous design and material integrity, further corroborate the financial viability of opting for high-quality vertical thermal oil heaters. In closing, vertical thermal oil heaters stand as a testament to engineering progress, marrying efficiency with sustainability. As industry demands evolve, these heaters remain indispensable, offering cutting-edge solutions that harmonise with the pressing needs for economical and eco-friendly industrial processes. The narrative of their excellence will continue to shape sectors looking to optimise thermal management technologies, cementing their place as a cornerstone in industrial innovation.

Latest news

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025

-

High-Efficiency Thermal Oil Boiler for Industrial Heating SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers for Industrial EfficiencyNewsJul.28,2025