high quality waste heat recovery steam boiler

High-Quality Waste Heat Recovery Steam Boilers

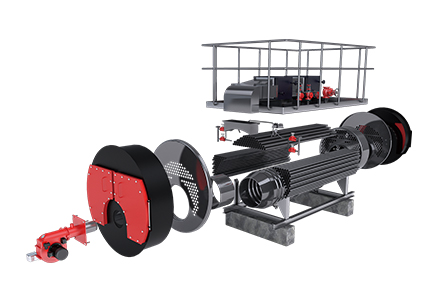

The increasing focus on energy efficiency and sustainability has led industries to seek innovative solutions for optimizing energy usage. One such solution is the implementation of high-quality waste heat recovery steam boilers. These systems utilize waste heat generated from various industrial processes and convert it into useful steam, thereby enhancing overall energy efficiency and reducing environmental impact.

Waste heat recovery steam boilers are designed to capture excess heat produced by machines, processes, or combustion reactions. This heat is typically lost to the atmosphere or through exhaust gases, representing a significant energy loss. By harnessing this waste heat, industries can significantly decrease their fuel consumption and operating costs. The primary function of these boilers is to recover and convert waste heat into steam, which can then be used for various applications such as heating, power generation, or as feedwater for additional boilers.

One of the key advantages of high-quality waste heat recovery steam boilers is their ability to improve energy efficiency. By utilizing fuel that has already been partially combusted, these boilers require less additional energy input to generate steam. This not only conserves raw materials but also leads to lower greenhouse gas emissions, aligning with global sustainability goals. Enhanced energy recovery systems can achieve efficiency rates exceeding 90%, making them a desirable choice for industries looking to minimize their carbon footprint.

high quality waste heat recovery steam boiler

The design of waste heat recovery steam boilers is critical for ensuring optimal performance. High-quality systems are equipped with advanced heat exchangers that maximize heat recovery potential. These components are designed to withstand high temperatures and pressures, ensuring durability and longevity. Additionally, modern boiler systems are often equipped with computerized control mechanisms that allow for real-time monitoring and adjustments, leading to improved operational efficiency and safety.

Industries such as power generation, oil and gas, cement, and manufacturing are particularly well-suited for waste heat recovery technologies. In the power generation sector, for instance, combined cycle power plants utilize waste heat from gas turbines to produce steam, which drives steam turbines for additional electricity generation. Similarly, in cement production, significant heat is available from kiln exhaust, which can be captured and converted into useful steam for process needs or electricity generation.

Moreover, the implementation of high-quality waste heat recovery steam boilers can lead to substantial cost savings over time. Although the initial investment may be higher than traditional boilers, the long-term benefits, including reduced fuel consumption and lower operational costs, can result in a favorable return on investment. Additionally, companies that prioritize energy efficiency often experience enhanced brand reputation and competitiveness in the marketplace.

In conclusion, high-quality waste heat recovery steam boilers represent a vital technology in the pursuit of energy efficiency and sustainability. By capturing and utilizing waste heat, these systems not only enhance the efficiency of industrial processes but also contribute to significant reductions in operational costs and environmental impact. As industries worldwide continue to adapt to changing energy landscapes, the adoption of waste heat recovery technologies will undoubtedly play a key role in achieving their sustainability objectives. Investing in these advanced systems is not only a smart economic decision but also a crucial step towards a more sustainable future.

-

High-Efficiency OEM Steam Boilers w/GPT-4-TurboNewsAug.02,2025

-

Advanced Electric Steam Boiler Manufacturers | GPT-4 Turbo AINewsAug.01,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025