industrial boiler manufacturers

Industrial Boiler Manufacturers Driving Efficiency and Sustainability in the Industry

Industrial boiler manufacturers play a pivotal role in various sectors, including energy, manufacturing, and food processing. These manufacturers are responsible for designing, producing, and maintaining boilers that meet the diverse needs of industries around the globe. With an ever-increasing focus on efficiency and sustainability, the industry has witnessed remarkable advancements over the years.

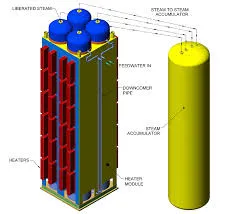

The primary function of an industrial boiler is to generate steam or hot water for various applications, such as heating, power generation, and processing. Different industries require specialized boilers that can address their specific operational demands. Consequently, manufacturers have developed a wide array of boiler types, including fire-tube, water-tube, electric, and biomass boilers. Each type has its unique advantages and is suited for different applications depending on factors such as capacity, efficiency, and environmental regulations.

One significant trend among industrial boiler manufacturers is the shift towards energy efficiency. With energy costs rising and regulatory pressures increasing, businesses are more motivated than ever to invest in high-efficiency boilers that can reduce fuel consumption and lower emissions. Many manufacturers have responded by incorporating advanced technologies in their designs, such as condensing heat exchangers, variable frequency drives, and automated control systems. These innovations not only improve operational efficiency but also enhance the overall sustainability of industrial processes.

industrial boiler manufacturers

Moreover, the focus on renewable energy sources has propelled the development of biomass boilers. These boilers utilize organic materials, such as wood pellets or agricultural waste, as fuel. This shift towards biomass and other renewable energy solutions has been largely driven by government policies and incentives aimed at reducing greenhouse gas emissions. Leading industrial boiler manufacturers are now dedicating resources to research and development projects that explore new renewable fuels and technologies, solidifying their commitment to sustainability.

In addition to energy efficiency, industrial boiler manufacturers are prioritizing safety and compliance. Adhering to stringent regulations and safety standards is crucial for manufacturers, as the implications of non-compliance can be significant. This has prompted manufacturers to invest in advanced safety features and robust testing protocols to ensure their products are reliable and safe for industrial use. Training and certification programs for operators are also vital in mitigating risks associated with boiler operation, underscoring the importance of a well-trained workforce.

Collaboration is another trend shaping the industrial boiler manufacturing landscape. Many manufacturers are partnering with technology firms, research institutions, and environmental organizations to accelerate innovation and address industry challenges. These collaborations enable the sharing of knowledge, resources, and best practices, ultimately leading to the development of more efficient and sustainable boiler solutions.

In conclusion, industrial boiler manufacturers are essential players in driving efficiency and sustainability within various industries. Their commitment to developing advanced, energy-efficient solutions that comply with safety standards is crucial as industries face mounting pressures to optimize performance while minimizing their environmental footprint. As technology continues to evolve, these manufacturers are well-positioned to lead the sector in helping companies navigate the complexities of modern operational demands, ensuring a sustainable future for the industrial landscape.

-

Electric Steam Boiler Manufacturers: High-Efficiency Industrial SolutionsNewsAug.27,2025

-

Leading Electric Steam Boiler Manufacturers | Efficient IndustrialNewsAug.26,2025

-

Electric Steam Boiler Manufacturers: Efficient, Reliable SolutionsNewsAug.25,2025

-

Electric Steam Boiler Manufacturers: Efficient & Reliable Industrial SolutionsNewsAug.24,2025

-

Reliable Electric Steam Boiler Manufacturers & Industrial SolutionsNewsAug.23,2025

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.21,2025