Efficient Solutions for Industrial Waste Heat Boiler Pricing and Quotes

Understanding Industrial Waste Heat Boiler Quotes

In the realm of industrial operations, energy efficiency is a key focus for businesses looking to reduce costs and minimize their environmental footprints. One effective solution to enhance energy efficiency is the implementation of waste heat recovery systems through industrial waste heat boilers. These boilers utilize residual heat generated from industrial processes to produce steam or hot water, thus improving overall energy utilization. However, before investing in such systems, it's crucial to understand the quotes and costs involved.

What is an Industrial Waste Heat Boiler?

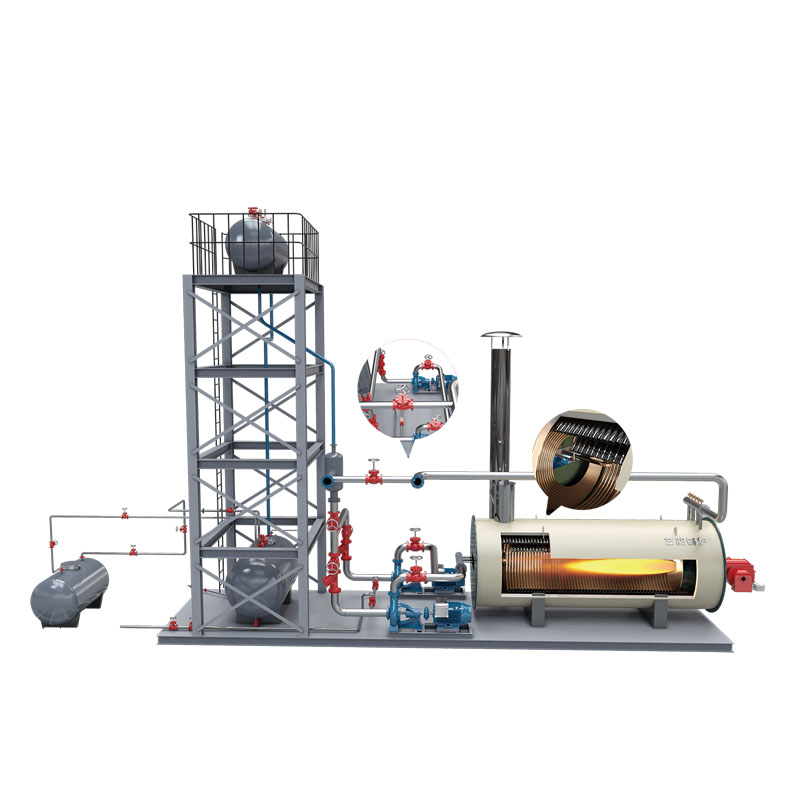

Industrial waste heat boilers are specialized devices designed to capture and recycle waste heat from various industrial processes, such as power generation, manufacturing, or chemical production. The captured heat energy can be repurposed for heating applications or converted into electricity, significantly reducing energy consumption and associated costs.

Factors Influencing Quotes

When looking for quotes on industrial waste heat boilers, several factors come into play

1. Type of Waste Heat Boiler Different designs and technologies cater to specific industrial applications. For instance, air-cooled, water-cooled, and fire-tube boilers have varied heat recovery efficiencies and costs. Understanding the suitable type for your specific needs is crucial for obtaining an accurate quote.

2. Heat Source Temperature The temperature of the waste heat from the process affects the boiler design and efficiency. Higher temperature sources may yield better energy recovery but require more advanced systems, influencing overall costs.

industrial waste heat boiler quotes

3. Capacity Requirements The size and capacity of the boiler must align with the operational needs of the facility. Providing accurate data about the expected heat load is essential for precise quoting.

4. Integration Complexity The complexity involved in integrating the waste heat boiler with existing systems can significantly impact the overall cost. A thorough assessment of the current infrastructure and potential modifications required will aid in understanding the quotes better.

5. Manufacturer Specifications Different manufacturers may offer varied pricing based on their technologies, materials, and support structures. It is advisable to conduct market research and obtain multiple quotes to compare offerings versus cost.

Evaluating Quotes

When assessing quotes for industrial waste heat boilers, consider not only the upfront costs but also the long-term savings generated from increased efficiency and reduced energy consumption. Pay attention to warranties, maintenance services, and the manufacturer's reputation, as these aspects can significantly affect the boiler's overall performance and return on investment.

Conclusion

Investing in an industrial waste heat boiler can be a transformative decision for businesses aiming to enhance energy efficiency and reduce operational costs. Understanding the factors that influence quotes and carefully evaluating multiple options will empower industrial operators to make informed decisions. As industries continue to pursue sustainability, waste heat recovery systems stand out as practical solutions that not only benefit the bottom line but also contribute positively to environmental stewardship.

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025

-

High-Efficiency Thermal Oil Boiler for Industrial Heating SolutionsNewsJul.29,2025