natural gas forced hot water boiler factories

The Evolution and Impact of Natural Gas Forced Hot Water Boiler Factories

Natural gas forced hot water boilers have become a cornerstone in modern heating technologies. As the demand for efficient, sustainable heating solutions rises, the factories dedicated to their production play a crucial role in shaping the energy landscape. These factories not only contribute to economic growth but also align with the goals of reducing carbon footprints and enhancing energy efficiency.

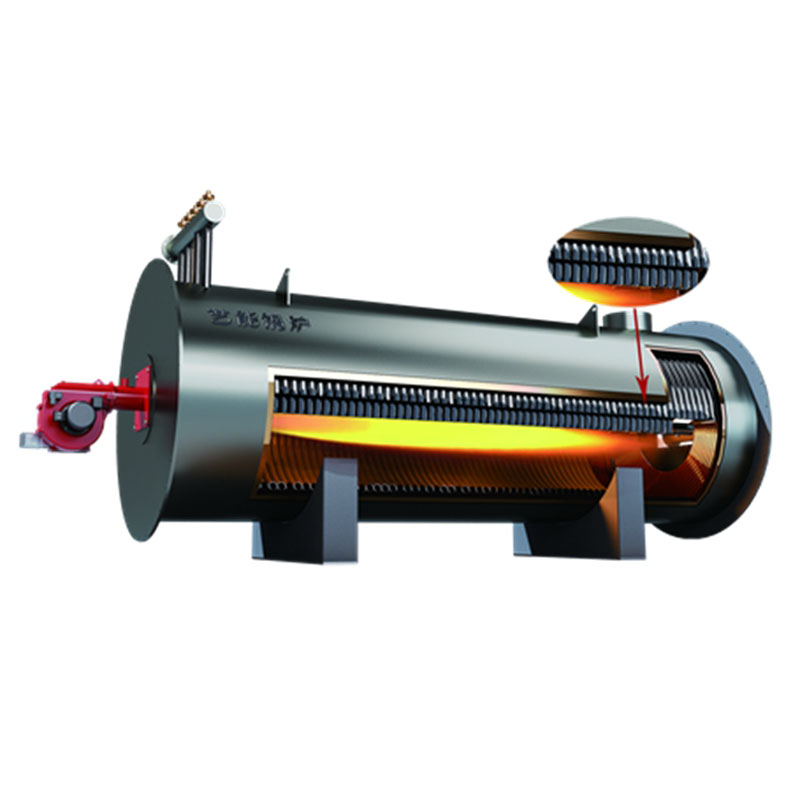

The manufacturing process of natural gas forced hot water boilers involves several stages, including design, engineering, assembly, and quality control. In the design phase, engineers focus on creating systems that maximize efficiency while adhering to stringent safety standards. Advanced computer-aided design (CAD) technologies are often employed to develop prototypes that go through rigorous testing for performance and safety.

Once the design is finalized, the engineering process begins, where the necessary materials are sourced. Factories typically use high-quality steel and advanced insulation materials to ensure that the boilers are durable and efficient. The assembly phase is where skilled technicians come in, meticulously putting together various components, including burners, heat exchangers, and control systems. This hands-on approach ensures quality and reliability in the final product.

natural gas forced hot water boiler factories

Quality control is paramount in the manufacturing of boilers, as safety is a top priority. Factories implement comprehensive testing procedures, including pressure tests and efficiency evaluations, to guarantee that each unit meets or exceeds industry standards. This emphasis on quality not only protects consumers but also bolsters the reputation of manufacturers in the competitive market.

Moreover, natural gas forced hot water boilers are celebrated for their energy efficiency. Compared to traditional heating methods, they offer quicker heating times and lower fuel consumption, which leads to reduced greenhouse gas emissions. The transition to natural gas heating technologies is part of a broader movement toward greener energy alternatives, significantly contributing to national and global efforts to combat climate change.

As countries strive to enhance their energy infrastructures, the demand for natural gas forced hot water boilers is expected to grow. Factories are responding not just by increasing production capacities but also by innovating their processes. Many are investing in automation and smart technologies that streamline operations and improve overall efficiency. This not only ensures that they can meet rising demand but also reduces operational costs, thereby making their products more affordable for consumers.

In conclusion, natural gas forced hot water boiler factories are pivotal in the transition toward efficient and sustainable heating solutions. Through advanced manufacturing processes, a commitment to quality, and a focus on innovation, these factories contribute significantly to energy efficiency and environmental sustainability. As we move forward, their role will only become more critical in addressing global energy challenges and promoting a cleaner, greener future.

-

Industrial Steam Boiler Corporation - Reliable Industrial Boiler Manufacturer & SupplierNewsJul.08,2025

-

High-Efficiency Steam Boiler Heat Exchanger Supplier & Factory Durable Products for IndustryNewsJul.08,2025

-

Premium Electric Steam Boiler Manufacturer Reliable Company & Factory SolutionsNewsJul.08,2025

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025

-

High-Efficiency Hotel Hot Water Boiler – Leading Exporters & Quotes for HotelsNewsJul.07,2025