Need a Thermal Oil Boiler with Precise Control & Efficiency?

Inside the YQW/L Heat Transfer Story: Gas/Diesel Fired Thermal Oil Heaters

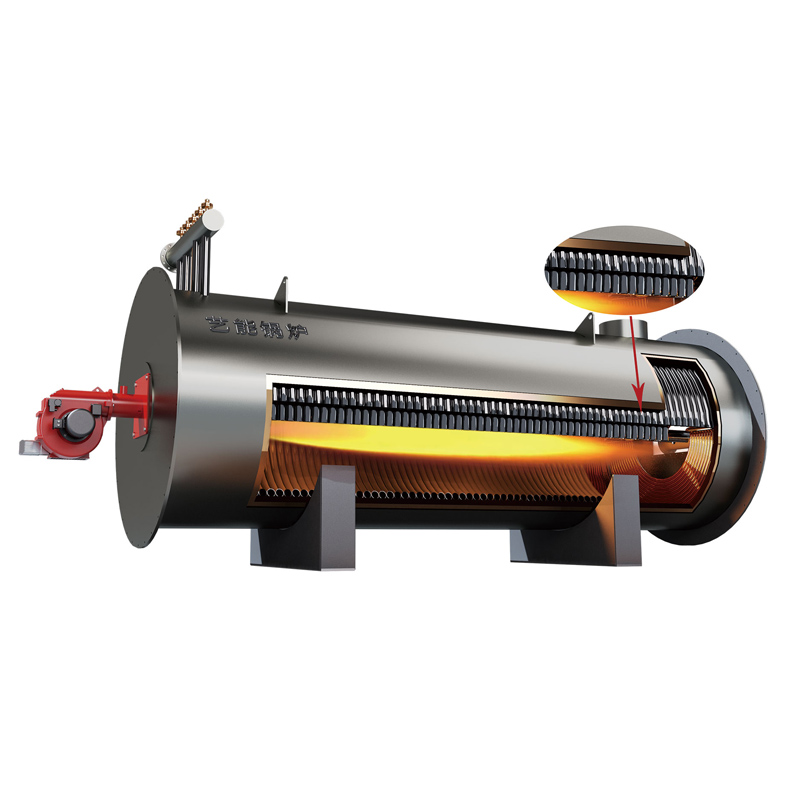

If you’re sizing up a thermal oil boiler for your plant, here’s the short version: the Horizontal/Vertical type YQW/L from Wuqiao, Hebei, China, is an efficient, low-stress workhorse with a wet-back internal-combustion two-pass design. The top coil tube shields the rear wall from direct flame, boosts radiant area, and—yes—nudges thermal efficiency upward. Simple idea, big impact.

What’s trending (and why it matters)

Across chemicals, textiles, food, asphalt, and wood panels, plants are shifting to closed-loop heat transfer oil systems for steady high temperatures—around 300–320°C—without the headaches of high-pressure steam. Lower maintenance, tighter control, better uptime. Honestly, the ROI case is getting hard to ignore, especially with low-NOx burners and smarter PLCs making emissions and tuning less of an ordeal.

Technical snapshot: YQW/L at a glance

- Wet-back, two-return coil design; top coil protects rear wall and evens out heat flux.

- Gas or diesel firing; compatible with low-NOx burners (Riello/Weishaupt-type options commonly requested).

- Coils in high-temp seamless tube (ASTM A106/EN 10216-2 equivalents), shell steel with mineral wool insulation and aluminum cladding.

- PLC control with oil flow/ΔT monitoring, interlocks for flow/temperature/flame safety.

| Spec (≈ values) | YQW/L Series |

|---|---|

| Heat capacity | 0.35–14 MW (≈300,000–12,000,000 kcal/h) |

| Working temperature | Up to 320°C (real-world use may vary with HTF) |

| Design pressure | ≈1.1 MPa (loop typically runs near atmospheric) |

| Thermal efficiency | 92–95% with proper tuning |

| Fuel | Natural gas / LPG / diesel oil |

| Controls | PLC + safety interlocks, optional remote monitoring |

| Emissions (low-NOx) | ≤80–120 mg/Nm³ NOx (burner dependent) |

| Certifications | PED/CE (on request), GB/T compliance; ASME options |

How it’s built and verified

Materials: seamless coil tube (ASTM A106/EN 10216), shell steel (Q235B/Q345R), mineral wool insulation. Methods: automated welding, PWHT where applicable, 100% visual + spot radiography/UT on critical joints. Testing: hydrostatic test at 1.5× design; control logic FAT; burner tuning with flue-gas analysis. Benchmarks: DIN 4754 for HTF systems, NFPA 87 for fluid heaters, PED/CE in the EU, and ASME where requested. Service life? With clean oil and routine sampling (acid number, carbon residue, flash point), 15–20 years is common.

Where it shines

- Textile dyeing and finishing: steady 180–220°C, fewer hotspots.

- Chemical/reactors: precise 250–300°C with tight ΔT control.

- Asphalt/bitumen: tanks and lines held at 160–200°C without coking drama.

- Wood/MDF presses and laminates: smooth heat profile equals smoother boards.

- Food & edible oils: careful thermal stability, low oxygen ingress.

Mini case: A dyeing plant (6 MW) swapped an ageing unit for a thermal oil boiler YQW configuration; gas usage dropped ≈7% after tuning, while operator callouts fell because the PLC started catching flow faults earlier. Not glamorous, but the maintenance team was thrilled.

| Vendor | Efficiency | Max Temp | Controls | Lead Time | Typical Price |

|---|---|---|---|---|---|

| Y&N YQW/L | ≈92–95% | ≈320°C | PLC, remote optional | 5–10 weeks | Competitive |

| Local Fabricator | ≈88–92% | ≈300°C | Basic | 3–6 weeks | Lower |

| EU Premium Brand | ≈93–96% | ≈330°C | Advanced | 10–16 weeks | Higher |

Customization and options

Horizontal or vertical footprint; gas/diesel burners; on-skid pump/filter set; economizer; nitrogen-blanketed expansion tank; SIL-rated safety loops; heat tracing manifolds. To be honest, many customers say the best upgrade is oil conditioning—cheap insurance for your thermal oil boiler.

Quality, compliance, and real test data

- Standards: DIN 4754, NFPA 87, PED/CE, ASME (as specified).

- Factory tests: hydro 1.5×; burner tuning with O2/CO/NOx logs; control FAT with simulated trips.

- Oil health: follow ASTM D6743 guidance; sample quarterly in the first year, then semi-annually.

Customer feedback has been surprisingly consistent: “smooth temperature control,” “cleaner stack numbers after the economizer,” and “easier to maintain than our old unit.” I guess that’s what you want from a thermal oil boiler—not drama, just reliable heat.

Origin: Wuqiao, Hebei, China. Note: specifications and performance depend on burner selection, heat transfer fluid, and site conditions.

Authoritative citations

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025