odm fire tube waste heat boiler

Understanding ODM Fire Tube Waste Heat Boilers Efficiency and Innovation

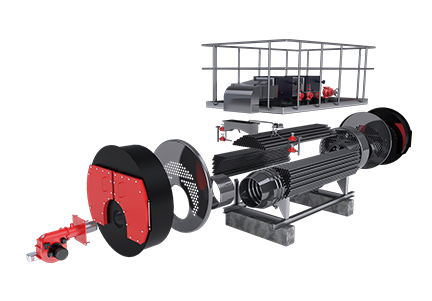

In the modern industrial landscape, the relentless pursuit of efficiency and sustainability has become paramount. One of the technologies that has gained prominence in this endeavor is the ODM fire tube waste heat boiler. This innovative solution harnesses waste heat from various industrial processes, converting it into usable energy. In this article, we will explore the workings, advantages, and applications of ODM fire tube waste heat boilers.

How It Works

The ODM fire tube waste heat boiler operates on a fairly straightforward principle it captures waste heat generated by industrial processes and uses it to produce steam or hot water. The design is based on the fire tube principle, where hot gases from the waste heat source flow through tubes that are surrounded by water. As the gases pass through the tubes, they transfer heat to the water, which raises its temperature. This process can be utilized in a variety of applications, including power generation, heating, and industrial processes.

The efficiency of these boilers largely depends on the temperature and volume of waste heat available. By capturing heat that would otherwise be lost, they significantly enhance the overall energy efficiency of industrial systems, reducing fuel consumption and greenhouse gas emissions.

Advantages of ODM Fire Tube Waste Heat Boilers

1. Energy Efficiency The primary advantage of ODM fire tube waste heat boilers is their ability to recover energy from waste heat. This not only lowers operational costs but also improves the overall energy efficiency of industrial facilities.

odm fire tube waste heat boiler

2. Environmental Sustainability By maximizing energy recovery, these boilers contribute to reduced emissions of carbon dioxide and other harmful pollutants. This is particularly important in industries where emissions regulations are becoming increasingly stringent.

3. Cost-Effective Solution While the initial investment in a waste heat boiler may be significant, the long-term savings on fuel and the potential for government incentives for energy-efficient technologies can make them a cost-effective solution.

4. Versatility ODM fire tube waste heat boilers can be applied in various industries, from petrochemical to manufacturing. They can be integrated into existing systems without major modifications, making them a versatile option for energy recovery.

Applications

The applications of ODM fire tube waste heat boilers are wide-ranging. In the chemical industry, for instance, they can effectively recover heat from exothermic reactions. In the steelmaking and glass industries, they capture heat from furnaces. Additionally, in power generation, they can assist in improving the overall thermal efficiency of plants by utilizing exhaust gas heat.

Conclusion

In conclusion, ODM fire tube waste heat boilers represent a significant advancement in industrial energy efficiency. By leveraging waste heat that would otherwise be lost, these boilers transform industrial operations and contribute to a more sustainable future. As industries continue to evolve, the adoption of such innovative technologies will be vital in meeting energy needs while minimizing environmental impact. The future lies in efficiency, and ODM fire tube waste heat boilers are poised to play a crucial role in this transformation.

-

High-Efficiency OEM Steam Boilers w/GPT-4-TurboNewsAug.02,2025

-

Advanced Electric Steam Boiler Manufacturers | GPT-4 Turbo AINewsAug.01,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025