oem gas fired thermal oil boiler

The Efficiency and Benefits of OEM Gas Fired Thermal Oil Boilers

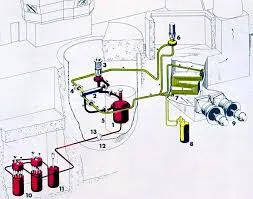

In the realm of industrial heating solutions, OEM (Original Equipment Manufacturer) gas fired thermal oil boilers have emerged as a popular choice for many businesses due to their remarkable efficiency and versatility. These boilers utilize gas as a fuel source and are designed to heat thermal oil, which in turn transfers heat to various industrial processes. Understanding the advantages of these systems can help manufacturers make informed decisions about their heating needs.

Efficiency and Performance

One of the most significant benefits of OEM gas fired thermal oil boilers is their high thermal efficiency. Unlike traditional steam boilers, which can experience heat loss due to steam condensation, thermal oil systems maintain their heat transfer efficiency even at high temperatures. This is largely because thermal oil can operate at temperatures up to 400°C (752°F) without any pressure, avoiding the complications associated with steam pressure systems. The improved heat transfer characteristics of thermal oil enable lower fuel consumption and reduced operating costs.

Additionally, these boilers are designed for seamless operation. OEM manufacturers typically offer models that are customized to specific industrial needs, ensuring optimal performance. The insulation around the thermal oil system minimizes heat loss, thereby enhancing overall efficiency. Regular maintenance and monitoring further ensure that the boiler operates at peak performance, contributing to sustainability goals by minimizing waste.

Versatility

Another critical advantage of OEM gas fired thermal oil boilers lies in their versatility. These systems can be employed across various industries, including food processing, petrochemicals, pharmaceuticals, plastics, and textiles, among others. The ability to maintain precise and constant temperature control makes thermal oil boilers ideal for a range of applications, from heat treatment to drying processes.

Furthermore, thermal oil systems can accommodate different configurations, such as electric or resistive heating elements. This flexibility allows manufacturers to tailor their heating solutions to their specific operational requirements, ensuring efficiency and productivity.

oem gas fired thermal oil boiler

Environmental Benefits

The environmental impact of industrial operations is an increasingly significant concern. OEM gas fired thermal oil boilers provide a greener alternative compared to traditional fuel systems. Utilizing natural gas or biogas as fuel sources results in lower emissions of greenhouse gases and particulates. Moreover, the high efficiency of these boilers means that less fuel is consumed, further reducing the overall environmental footprint.

Many OEM manufacturers are incorporating advanced technologies to enhance the emissions control mechanisms in their thermal oil systems. Such innovations can help operators comply with stringent environmental regulations while contributing to corporate sustainability initiatives.

Reliability and Safety

Safety is a paramount concern in industrial operations. OEM gas fired thermal oil boilers are designed with numerous safety features to mitigate risks. Automatic flame monitoring and primary/secondary safety control systems ensure safe operation. Additionally, modern thermal oil boilers are equipped with pressure relief systems and thermal expansion controls to prevent overheating and system failures.

Moreover, because thermal oil operates at lower pressures compared to steam, the overall risk of catastrophic failures is significantly reduced. This reliability makes gas fired thermal oil boilers a safe choice for industries requiring consistent and dependable heating capabilities.

Conclusion

In conclusion, OEM gas fired thermal oil boilers are an exceptional solution for industries seeking high efficiency, versatility, and safety in their heating systems. Their ability to operate at high temperatures without the complications of steam pressure, combined with environmental advantages and flexible applications, positions them as a preferred choice in the industrial sector. By investing in these advanced systems, businesses can enhance their operational efficiency while contributing towards a more sustainable future. As the industry evolves, the continued development of these technologies will undoubtedly drive further improvements in efficiency and safety.

-

High-Efficiency OEM Steam Boilers w/GPT-4-TurboNewsAug.02,2025

-

Advanced Electric Steam Boiler Manufacturers | GPT-4 Turbo AINewsAug.01,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025