oem low water cut off steam boiler

The Importance of Low Water Cut-Off in Steam Boilers

The Importance of Low Water Cut-Off in Steam Boilers

The primary function of the low water cut-off is to prevent the boiler from operating with insufficient water levels. Water is crucial in the steam generation process, as it absorbs heat and converts into steam. If the water level drops too low, the boiler can overheat, potentially leading to catastrophic failures, such as boiler explosions or component damage. The LWCO monitors the water level in the boiler and automatically shuts off the burner if the water level falls below a predetermined point. This protective measure is crucial not only for the safety of the equipment but also for the safety of personnel working in close proximity to the boiler.

oem low water cut off steam boiler

In addition to enhancing safety, implementing a low water cut-off can contribute to the overall efficiency of a steam boiler. Maintaining the correct water level ensures that the system operates optimally, preventing overheating and excessive fuel consumption. When a boiler runs dry due to low water levels, it can lead to increased energy costs and a shorter lifespan for the equipment. Therefore, the LWCO not only helps safeguard personnel and infrastructure but also promotes economic efficiency in boiler operation.

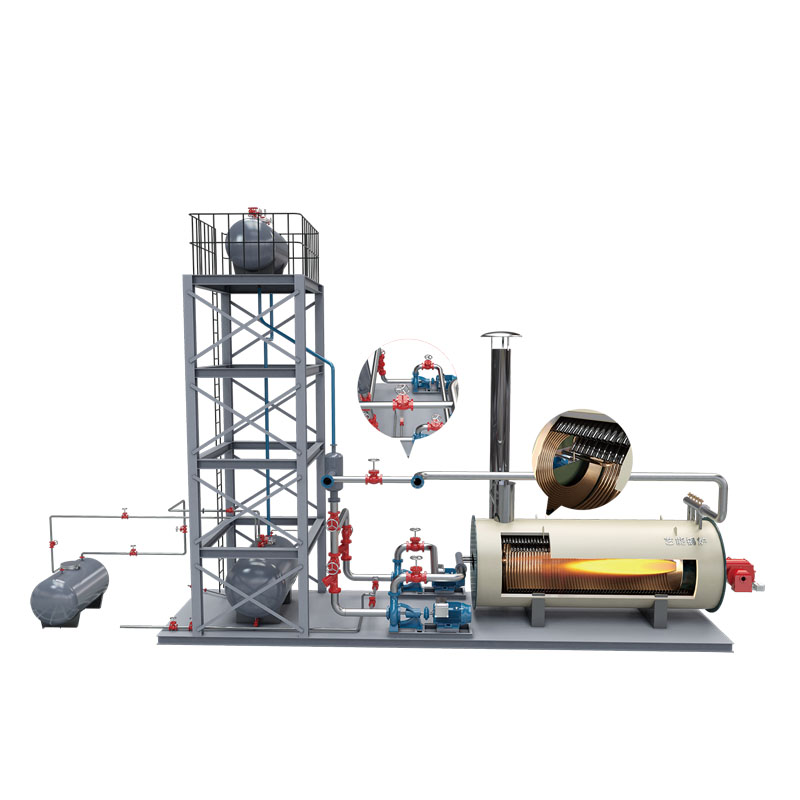

Installing an OEM (Original Equipment Manufacturer) low water cut-off device is highly advisable for any steam boiler system. OEM devices are specifically designed for compatibility with particular boiler models, ensuring better performance and reliability. These devices often come with advanced features, including automatic reset, testing functions, and alarm systems to alert operators of any low water conditions. By choosing OEM products, facilities can ensure they receive high-quality, dependable safety devices tailored to their boiler systems.

In conclusion, the low water cut-off is an indispensable feature for the safe and efficient operation of steam boilers. It protects against the dangers of operating with inadequate water levels, enhances energy efficiency, and reduces the likelihood of costly repairs or replacements. Investing in a reliable OEM low water cut-off system is an essential step for industries relying on steam boilers, ensuring both safety and operational effectiveness. Overall, prioritizing the implementation of a low water cut-off can lead to better performance, prolonged equipment life, and peace of mind for operators.

-

Industrial Steam Boiler Corporation - Reliable Industrial Boiler Manufacturer & SupplierNewsJul.08,2025

-

High-Efficiency Steam Boiler Heat Exchanger Supplier & Factory Durable Products for IndustryNewsJul.08,2025

-

Premium Electric Steam Boiler Manufacturer Reliable Company & Factory SolutionsNewsJul.08,2025

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025

-

High-Efficiency Hotel Hot Water Boiler – Leading Exporters & Quotes for HotelsNewsJul.07,2025