OEM Steam Boilers for Efficient Oil Heating Solutions and Performance Enhancement

Understanding OEM Oil Steam Boilers Efficiency and Reliability in Industrial Applications

In the realm of industrial heating solutions, the OEM (Original Equipment Manufacturer) oil steam boiler stands out as a critical component for various processes. These boilers provide reliable steam generation essential for industries such as food processing, pharmaceuticals, and manufacturing. This article explores the features, benefits, and considerations associated with OEM oil steam boilers.

What is an OEM Oil Steam Boiler?

An OEM oil steam boiler is specifically designed and manufactured by a company that specializes in producing boiler systems. These boilers utilize oil as a fuel source to generate steam, which can then be utilized for powering machinery, heating, and other industrial processes. The term “OEM” emphasizes the quality and reliability of the product, as these manufacturers are known for adhering to strict industry standards and regulations.

Efficiency and Performance

One of the primary advantages of OEM oil steam boilers is their efficiency. Modern designs incorporate advanced technology to maximize fuel utilization while minimizing waste. High-efficiency burners, heat exchangers, and insulation materials contribute to lower operational costs. By achieving high levels of thermal efficiency, businesses can reduce their fuel consumption significantly, leading to cost savings and a lower environmental impact.

Moreover, OEM oil steam boilers are built to handle fluctuating demand with ease. They can generate steam quickly, ensuring that production processes are not interrupted. This responsiveness is crucial for industries where downtime can lead to significant financial losses.

Reliability and Durability

Reliability is another hallmark of OEM oil steam boilers. Manufacturers build these systems to withstand rigorous operating conditions, and they are equipped with features that enhance durability. Regular maintenance and adherence to the manufacturer's guidelines can significantly extend the lifespan of these boilers.

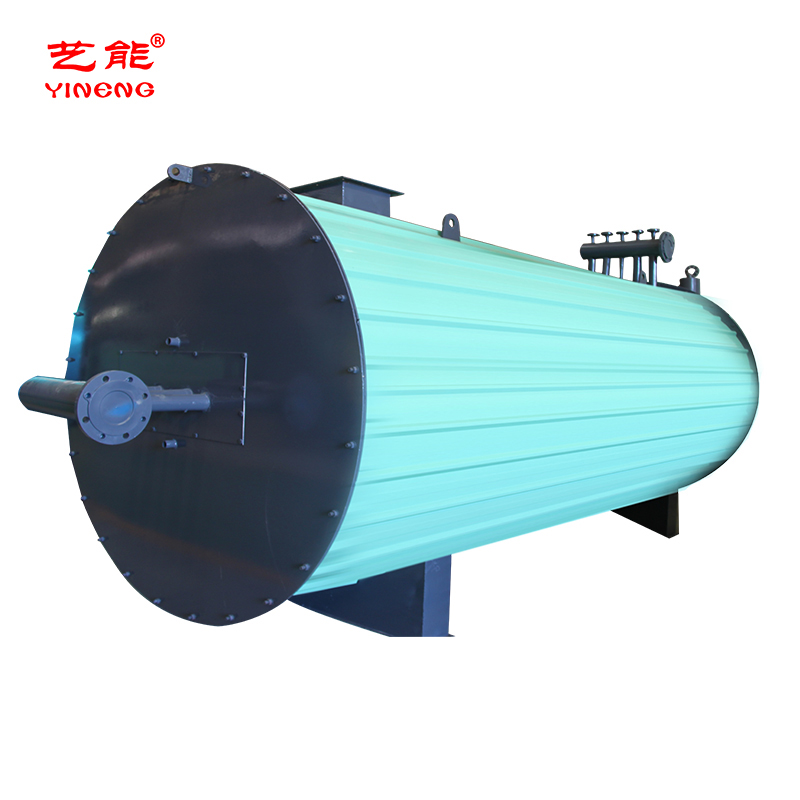

oem oil steam boiler

Furthermore, OEM manufacturers often provide comprehensive support services, including installation, maintenance, and repair. This level of service ensures that any potential issues can be addressed promptly, minimizing downtime and ensuring continuous operation.

Environmental Considerations

As industries increasingly focus on sustainability, the environmental impact of any equipment is a vital consideration. OEM oil steam boilers are designed to meet stringent environmental regulations. They incorporate features such as advanced emissions control systems, which help reduce pollutants released into the environment. By opting for such efficient and eco-friendly solutions, businesses can enhance their sustainability profile while remaining compliant with regulatory requirements.

Choosing the Right OEM Oil Steam Boiler

When selecting an OEM oil steam boiler, various factors need to be considered. The size and capacity of the boiler must align with the specific steam generation needs of the facility. Additionally, understanding the fuel types available and the operating costs associated with each is crucial for making an informed decision.

It’s also beneficial to evaluate the manufacturer’s reputation, warranty offerings, and the customer support they provide. A reputable OEM will not only ensure high-quality products but also offer extensive service and support, making the investment more worthwhile.

Conclusion

OEM oil steam boilers are indispensable in numerous industrial applications due to their efficiency, reliability, and potential for environmental compliance. By leveraging advanced technology and superior manufacturing practices, these boilers serve as a cornerstone for many operational processes. For businesses looking to optimize their steam generation systems, investing in an OEM oil steam boiler can lead to significant improvements in productivity and cost reduction, while also contributing to a greener future.

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025

-

High-Efficiency Thermal Oil Boiler for Industrial Heating SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers for Industrial EfficiencyNewsJul.28,2025