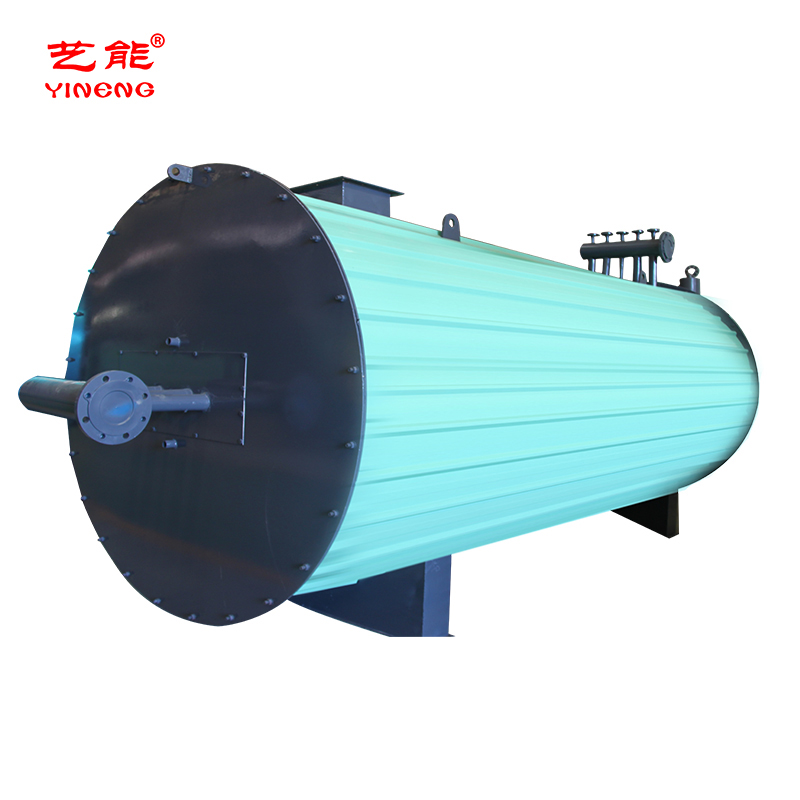

oem thermal oil boiler manufacturer

The Importance of OEM Thermal Oil Boiler Manufacturers

In the industrial landscape, maintaining optimal operational efficiency is paramount for success. One of the critical components that significantly contribute to this efficiency is the heating system, particularly thermal oil boilers. Original Equipment Manufacturer (OEM) thermal oil boilers play a pivotal role in various sectors, including chemical processing, food production, and renewable energy. Understanding the advantages of OEM thermal oil boilers and their manufacturers is crucial for businesses seeking reliable and efficient heating solutions.

What Are Thermal Oil Boilers?

Thermal oil boilers are specialized systems that use thermal fluid as the heat transfer medium. Unlike traditional water boilers, these systems operate at higher temperatures and lower pressures, providing more extensive heat transfer capabilities. This characteristic makes thermal oil boilers ideal for applications requiring consistent and high-temperature heat, such as in oil refineries and textile manufacturing.

The Role of OEM Manufacturers

OEM thermal oil boiler manufacturers focus on designing and producing boilers tailored to specific industrial needs. By leveraging advanced engineering and technology, these manufacturers create customized systems that meet unique operational requirements. This specialization leads to a variety of advantages

1. Customization OEM manufacturers can design thermal oil boilers that align perfectly with a client's specific applications and operational goals. Custom features may include enhanced safety measures, increased thermal efficiency, and integration with existing systems.

oem thermal oil boiler manufacturer

2. Quality Assurance Established OEM manufacturers adhere to rigorous quality standards. This commitment to quality ensures that the thermal oil boilers are reliable and durable, minimizing unexpected downtimes and maintenance costs.

3. Advanced Technology With continuous advancements in technology, OEM manufacturers are at the forefront of innovation. They incorporate the latest energy-efficient technologies in their thermal oil boilers, helping clients reduce energy consumption and operational costs.

4. Comprehensive Support Partnering with an OEM manufacturer often comes with added benefits, such as dedicated customer support, installation guidance, and ongoing maintenance services. This relationship can significantly enhance operational efficiency and extend the lifecycle of the equipment.

Economic and Environmental Benefits

Investing in OEM thermal oil boilers also translates to economic benefits. By ensuring higher energy efficiency, these systems contribute to reduced energy bills and lower carbon footprints. Furthermore, many OEM manufacturers focus on sustainable practices, providing options for eco-friendly thermal oils and designs that comply with environmental regulations.

Conclusion

In conclusion, choosing an OEM thermal oil boiler manufacturer is a strategic decision that can greatly enhance operational efficiency and reliability in industrial processes. With customized solutions, superior quality, and a commitment to innovation, OEM manufacturers provide the tools necessary for industries to thrive in today’s competitive market. For businesses looking to optimize their heating systems, collaborating with a reputable OEM manufacturer is a step toward achieving greater operational excellence and sustainability.

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025

-

High-Efficiency Thermal Oil Boiler for Industrial Heating SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers for Industrial EfficiencyNewsJul.28,2025