oil heater for hot press machine manufacturers

The Importance of Oil Heaters in Hot Press Machines A Guide for Manufacturers

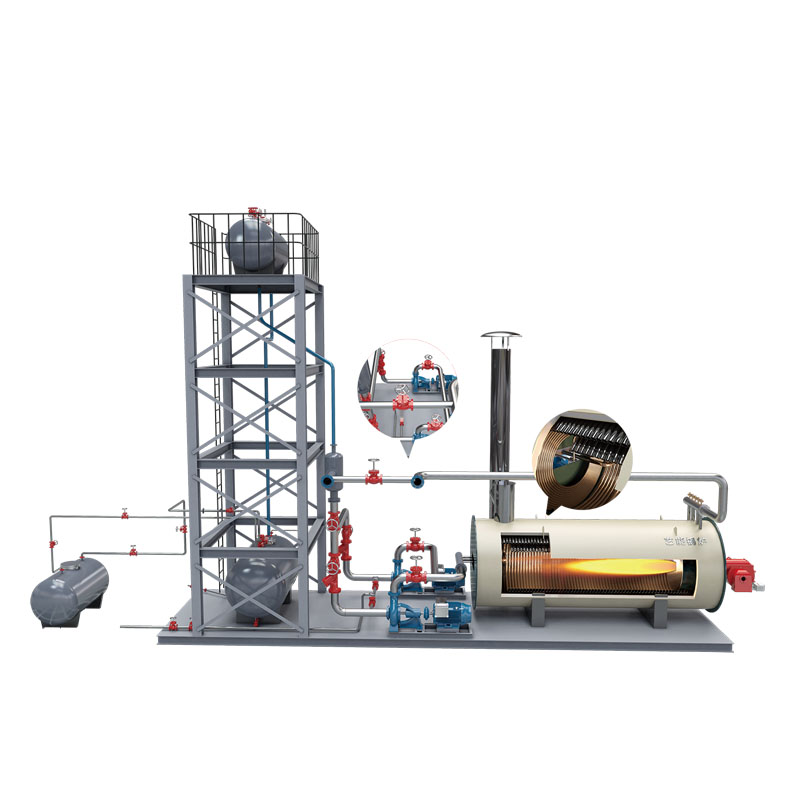

In the manufacturing industry, particularly in sectors dealing with composite materials, wood products, and various types of plastics, hot press machines play a pivotal role. These machines are designed to combine heat and pressure to form, mold, and enhance the properties of materials. A critical component of these machines is the oil heater, which is essential for delivering the high temperatures required for effective processing. In this article, we will explore the importance of oil heaters specifically tailored for hot press machine manufacturers.

Understanding Hot Press Machines

Hot press machines utilize heat and pressure to transform raw materials into finished products. This method is widely used in the production of laminated wood, composite panels, and other engineering materials. The efficiency of this process relies heavily on the ability to maintain consistent temperatures across the pressing plates. Any fluctuation in temperature can lead to unsatisfactory results, making the oil heating system a vital element of the machine.

The Role of Oil Heaters

Oil heaters work by circulating heated oil through the machine's platens, ensuring that they reach and maintain the desired temperature. Unlike other heating methods, such as electric or steam heaters, oil heaters provide several advantages

1. Consistent Heating Oil heaters offer uniform temperature distribution, which is crucial for achieving consistent results. This uniformity helps in maintaining the integrity of the products being manufactured.

2. Energy Efficiency Oil heating systems are known for their energy efficiency. They provide a higher thermal conductivity compared to other heating methods, allowing for quicker heat-up times and reduced energy consumption.

3. Reduced Risk of Overheating The thermal mass of oil allows it to absorb and retain heat effectively, reducing the risk of overheating the press. This is particularly important in avoiding damage to sensitive materials.

4. Versatility Oil heaters can be used for various temperature ranges and applications, making them suitable for different types of hot press operations. This versatility is essential for manufacturers that need to switch between product types.

oil heater for hot press machine manufacturers

Selecting the Right Oil Heater

When it comes to choosing an oil heater for a hot press machine, manufacturers should consider several factors

- Temperature Range Identify the maximum temperature required for your specific application and ensure the heater can meet those needs.

- Oil Type Different types of heating oils have varying thermal properties. Manufacturers should select an oil that is compatible with their specific temperature requirements and machine design.

- System Design The heater should integrate seamlessly with the hot press machine’s design. Consideration must be given to the layout, size, and connection ease to ensure optimal performance.

- Maintenance Requirements Regular maintenance is essential for the longevity and efficiency of oil heaters. Manufacturers should choose heaters that are easy to service and maintain to reduce downtime.

Conclusion

In conclusion, the role of oil heaters in hot press machines cannot be overstated. They ensure efficient, consistent heating essential to quality manufacturing processes. When selecting an oil heater, manufacturers should carefully evaluate their specific requirements and the equipment's capabilities. By investing in high-quality oil heating systems, manufacturers can significantly improve their production efficiency, reduce energy costs, and enhance product quality.

As the demand for advanced materials continues to grow, the importance of reliable and efficient oil heaters in hot press machinery will become increasingly critical. Manufacturers who prioritize these components can expect to see improved operational efficiency and a competitive edge in the marketplace.

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025

-

High-Efficiency Thermal Oil Boiler for Industrial Heating SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers for Industrial EfficiencyNewsJul.28,2025