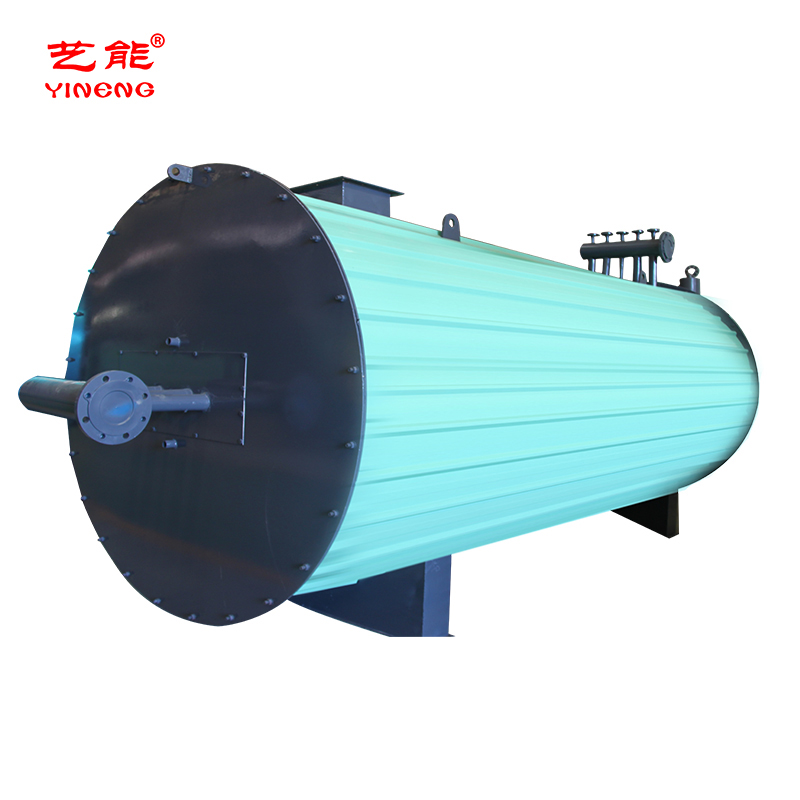

pellet hot water boiler factories

The Rise of Pellet Hot Water Boiler Factories A Sustainable Solution for Modern Heating Needs

In the world of heating solutions, the urgency for sustainable and renewable energy sources has never been greater. Amidst the growing concerns regarding climate change and the depletion of fossil fuels, pellet hot water boilers have emerged as a promising alternative. Pellet hot water boiler factories are sprouting up globally, contributing significantly to the green energy movement and catering to the demand for efficient heating systems.

Pellet boilers are designed to burn biomass pellets made from compressed wood or agricultural residues. These pellets are not only a renewable resource but also provide a clean-burning option that results in reduced carbon emissions compared to traditional fossil fuels. As people become more environmentally conscious, the appeal of pellet hot water systems increases. Factories specializing in these boilers are capitalizing on this trend by innovating and improving manufacturing processes to meet the rising demand.

One of the primary advantages of pellet hot water boilers is their efficiency. Modern systems are designed to achieve high thermal efficiency, which means that they convert a significant portion of the energy stored in pellets into usable heat. This efficiency is achieved through advanced combustion technologies that optimize the burning process, ensuring minimal waste and maximum output. As factories invest in research and development, new designs continue to reduce emissions, making these systems even cleaner and more efficient.

Cost-effectiveness is another attractive feature of pellet hot water boilers. While the initial investment might be higher than that of conventional boilers, the long-term savings on fuel costs can be substantial. Pellets are often cheaper than oil or gas, and with stable pricing, homeowners can better predict their heating expenses. Additionally, many countries offer incentives for renewable energy installations, making pellet boilers an economically viable option for many.

pellet hot water boiler factories

The growth of pellet hot water boiler factories also stimulates local economies. These factories often create jobs in manufacturing, engineering, and installation. By sourcing raw materials locally, they contribute to regional economies and promote sustainable practices. Moreover, as the industry expands, it encourages the development of a supply chain that fosters innovation and creates synergy between producers of biomass pellets and boiler manufacturers.

Despite the numerous advantages, the industry does face challenges. One of the main hurdles is the need for adequate infrastructure for pellet production and distribution. Access to quality biomass pellets can be limited in some areas, which may deter potential users from investing in pellet hot water systems. Additionally, public awareness about the benefits of these systems remains relatively low compared to traditional heating methods. To overcome these challenges, comprehensive education and clear information campaigns are essential.

The future of pellet hot water boiler factories appears bright, with increasing global interest in sustainable heating solutions. As technology improves and public awareness grows, the adoption of pellet systems is likely to rise. The versatility of pellet boilers makes them suitable for various applications, from residential buildings to commercial and industrial uses.

In conclusion, pellet hot water boiler factories play a crucial role in the transition toward sustainable energy solutions. By harnessing the potential of biomass, these factories not only contribute to reducing carbon emissions but also support local economies and provide efficient heating alternatives. As more people recognize the environmental and economic benefits of pellet systems, the future of heating looks greener than ever. With ongoing advancements in technology and infrastructure, the shift toward pellet hot water boilers promises to reshape the landscape of modern heating solutions, making sustainability a priority for future generations.

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.21,2025

-

Efficient Waste Heat Boilers: Energy Recovery SolutionsNewsAug.19,2025

-

Industrial Thermal Oil Boilers | Efficient & Reliable HeatingNewsAug.18,2025

-

Electric Steam Boiler Manufacturers: Efficient & Reliable SolutionsNewsAug.17,2025

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.15,2025

-

Leading Electric Steam Boiler Manufacturers for IndustryNewsAug.14,2025