PLC Automation Solutions for Efficient Boiler Control Systems and Management

PLC Control in Boiler Systems Enhancing Efficiency and Safety

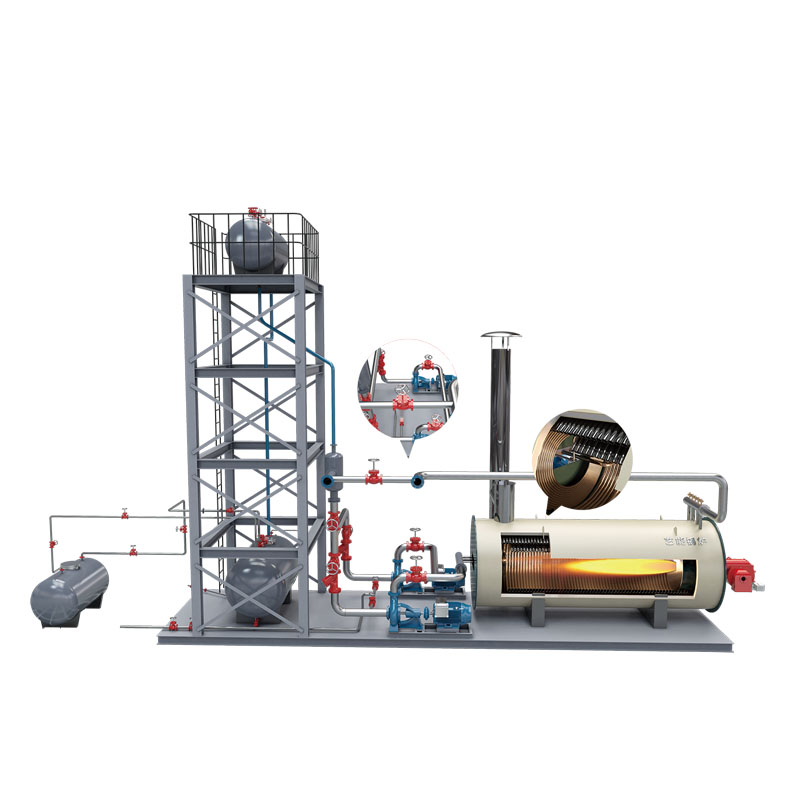

In the modern industrial landscape, the integration of advanced technology is critical for achieving operational efficiency, reliability, and safety. One of the areas where innovative technology has made significant strides is in the control of boiler systems. Programmable Logic Controllers (PLC) have emerged as a vital component in the automation and control of boilers, significantly improving performance and operational security.

PLC Control in Boiler Systems Enhancing Efficiency and Safety

One of the primary benefits of PLC control in boilers is the enhancement of efficiency. PLCs enable real-time monitoring and adjustments to boiler operations, ensuring that each component operates at optimal levels. For instance, by continuously assessing water levels and temperatures, a PLC can adjust the feedwater supply and fuel input, leading to reduced waste and improved fuel economy. This real-time approach not only saves costs but also minimizes the environmental impact of boiler operation by reducing emissions and fuel consumption.

plc control boiler company

Safety is another critical aspect where PLCs play a crucial role in boiler management. Boilers operate under high pressure and temperature, making safety a top priority. PLCs can implement strict control protocols to monitor various safety parameters, such as pressure levels, temperature thresholds, and emergency shutdown systems. If any readings go beyond the predefined safety limits, the PLC can automatically initiate shutdown procedures, alert operators, and even engage safety valves. This automatic response capability significantly reduces the risk of accidents and ensures compliance with safety regulations.

Furthermore, the use of PLCs in boiler systems allows for improved data management and analytics. Modern PLCs can integrate with supervisory control and data acquisition (SCADA) systems, enabling operators to visualize boiler performance through advanced graphical interfaces. This connectivity allows for extensive data logging, which can be used for predictive maintenance, troubleshooting, and operational assessment. By analyzing historical data, companies can identify patterns and anomalies, allowing for proactive solutions that prevent downtime and extend equipment life.

As industries worldwide focus on sustainability and operational efficiency, PLC-controlled boiler systems offer a pathway to achieving these goals. Customization options available in PLC programming allow companies to tailor their systems according to specific operational needs, thus maximizing performance. This flexibility is particularly beneficial in industries such as power generation, pharmaceuticals, and food processing, where boiler systems vary significantly in size and complexity.

In conclusion, the implementation of PLC control in boiler systems illustrates a significant advancement in industrial automation. By improving operational efficiency, enhancing safety measures, and providing robust data analytics, PLC technology has transformed how industries manage their boiler operations. As companies continue to embrace automation and seek ways to reduce costs while ensuring safety and environmental compliance, the role of PLCs in boiler control will undoubtedly continue to grow, paving the way for smarter, safer, and more efficient industrial practices.

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025

-

High-Efficiency Thermal Oil Boiler for Industrial Heating SolutionsNewsJul.29,2025