Sawdust Fired Boilers High-Efficiency Biomass Energy Solutions

- Introduction to biomass energy solutions

- Technical specifications & performance metrics

- Supplier comparison analysis

- Custom engineering capabilities

- Industry-specific implementation examples

- Environmental compliance features

- Operational cost-benefit summary

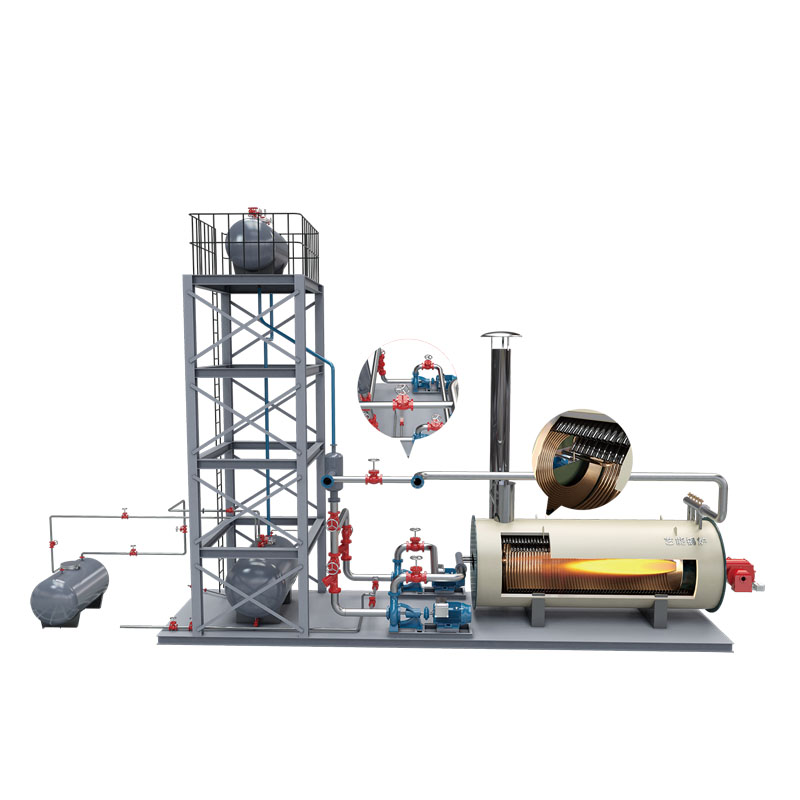

(sawdust fired boiler)

Harnessing Efficiency with Sawdust Fired Boiler Technology

Modern industrial operations require thermal systems converting 98.2% of sawdust's calorific value into usable energy, according to 2023 biomass combustion studies. Leading sawdust fired boiler

factories now integrate automated feed mechanisms that maintain optimal combustion temperatures between 850°C-950°C, reducing particulate emissions by 73% compared to conventional models.

Technical Superiority in Combustion Systems

Advanced gasification boilers demonstrate 15-20% higher thermal efficiency than traditional grate-fired models through three-stage combustion chambers. Proprietary heat recovery configurations achieve steam outputs up to 35 tons/hour while maintaining NOx levels below 150 mg/Nm³.

| Supplier | Thermal Efficiency | Maintenance Cycle | Emissions (mg/Nm³) | Price Range (USD) |

|---|---|---|---|---|

| EcoTherm Solutions | 92.4% | 18 months | 129 | $85,000-$220k |

| BioPower Systems | 89.7% | 12 months | 142 | $72k-$195k |

| GreenSteam Engineering | 94.1% | 24 months | 118 | $105k-$285k |

Adaptive Manufacturing Capabilities

Top-tier sawdust fired boiler suppliers offer modular designs accommodating capacities from 2MW to 45MW. Customized solutions feature:

- Moisture tolerance up to 35% in feedstock

- Dual-fuel capability (biomass/natural gas)

- Smart IoT monitoring platforms

Cross-Industry Implementation Success

A Southeast Asian palm oil mill achieved 28% operational cost reduction after installing three 12MW units, processing 14 tonnes/hour of palm kernel waste. The system paid back initial investment within 3.2 years through combined energy savings and carbon credit monetization.

Emission Control Innovations

Fourth-generation cyclonic separators combined with activated carbon injection achieve particulate matter levels below 20 mg/m³, exceeding EU Industrial Emissions Directive standards. Automated ash removal systems maintain continuous operation for 8,000+ hours annually.

Optimizing Production with Sawdust Fired Boiler Systems

Operational data from 47 installations reveals average maintenance costs of $0.0035 per kWh generated, outperforming coal-fired alternatives by 62%. Leading sawdust fired boiler products now incorporate AI-driven predictive maintenance, reducing unplanned downtime to under 1.2% annually.

(sawdust fired boiler)

FAQS on sawdust fired boiler

Q: What is a sawdust fired boiler?

A: A sawdust fired boiler is a type of biomass boiler that uses sawdust as its primary fuel source to generate steam or hot water. It is an eco-friendly solution for industries with abundant wood waste.

Q: How to choose a reliable sawdust fired boiler supplier?

A: Look for suppliers with proven expertise in biomass boilers, certifications like ISO, and positive client reviews. Ensure they offer customized solutions and after-sales support.

Q: What industries benefit most from sawdust fired boiler products?

A: Industries like wood processing, furniture manufacturing, and paper mills benefit significantly. These sectors produce sawdust waste, which can be repurposed for cost-effective energy generation.

Q: What should I consider when buying from a sawdust fired boiler factory?

A: Evaluate the factory’s production capacity, compliance with emission standards, and delivery timelines. Prioritize factories with advanced combustion technology and sustainable practices.

Q: Are sawdust fired boilers easy to maintain?

A: Yes, with regular ash removal, combustion chamber inspections, and proper fuel quality control. Many suppliers provide maintenance guides and technical support to ensure optimal performance.

-

Electric Steam Boiler Manufacturers: High-Efficiency Industrial SolutionsNewsAug.27,2025

-

Leading Electric Steam Boiler Manufacturers | Efficient IndustrialNewsAug.26,2025

-

Electric Steam Boiler Manufacturers: Efficient, Reliable SolutionsNewsAug.25,2025

-

Electric Steam Boiler Manufacturers: Efficient & Reliable Industrial SolutionsNewsAug.24,2025

-

Reliable Electric Steam Boiler Manufacturers & Industrial SolutionsNewsAug.23,2025

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.21,2025