Jun . 13, 2024 11:01

Back to list

Steam Boiler Suppliers for Beverage Production

The Pivotal Role of Steam Boilers in Beverage Manufacturing

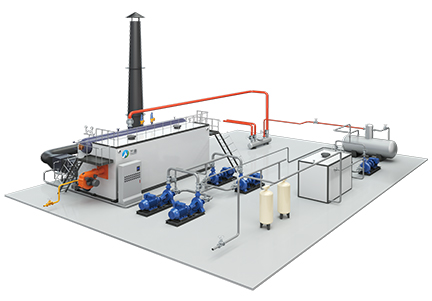

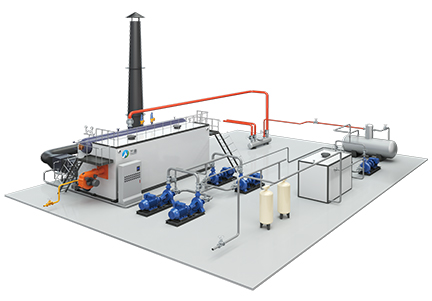

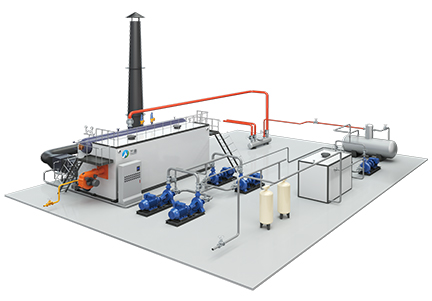

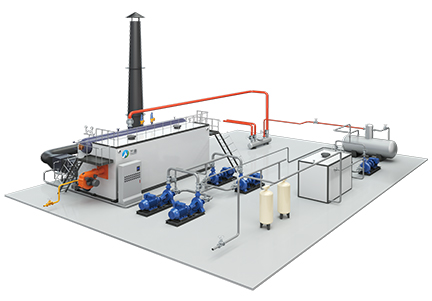

In the dynamic world of beverage manufacturing, steam boilers play an indispensable role. These high-pressure, heat-generating machines are the backbone of numerous production processes, ensuring the consistent quality and efficiency that characterizes the industry.

Steam boilers are the unsung heroes in the creation of our favorite beverages, from carbonated soft drinks to premium coffees and teas. They serve as a vital source of energy, driving a wide range of operations including pasteurization, sterilization, brewing, distillation, and even packaging.

The pasteurization process, for instance, is critical in preserving the freshness and safety of beverages. Steam generated by boilers is used to heat the beverages to a specific temperature, killing harmful microorganisms and extending shelf life. In the case of alcoholic beverages, the distillation process, where alcohol is separated from water and other components, is also steam-driven.

Moreover, steam is essential in the brewing process, particularly in the heating of grains and water to initiate the malting and mashing stages. It's also crucial in the coffee roasting process, where precise temperature control is necessary to develop the unique flavors and aromas.

In addition to these direct applications, steam boilers also power various ancillary equipment in a beverage plant, such as pumps, conveyor systems, and heating systems for water and cleaning solutions

In addition to these direct applications, steam boilers also power various ancillary equipment in a beverage plant, such as pumps, conveyor systems, and heating systems for water and cleaning solutions In addition to these direct applications, steam boilers also power various ancillary equipment in a beverage plant, such as pumps, conveyor systems, and heating systems for water and cleaning solutions

In addition to these direct applications, steam boilers also power various ancillary equipment in a beverage plant, such as pumps, conveyor systems, and heating systems for water and cleaning solutions

In addition to these direct applications, steam boilers also power various ancillary equipment in a beverage plant, such as pumps, conveyor systems, and heating systems for water and cleaning solutions

In addition to these direct applications, steam boilers also power various ancillary equipment in a beverage plant, such as pumps, conveyor systems, and heating systems for water and cleaning solutions steam boiler for beverages manufacturers. The steam's latent heat provides an efficient and cost-effective method for maintaining optimal temperatures in the plant, contributing to overall energy efficiency.

For manufacturers, choosing the right steam boiler is a strategic decision. Factors such as capacity, efficiency, fuel type, and automation level all influence the effectiveness of the boiler in meeting the specific demands of the beverage production process. Modern boilers, with their advanced controls and high thermal efficiency, offer not only reliability but also environmental benefits through reduced emissions.

In conclusion, steam boilers are more than just machinery; they are integral components in the intricate dance of beverage manufacturing. Their role is pivotal, shaping the taste, safety, and quality of the beverages we enjoy daily. As technology advances, so too does the functionality and efficiency of steam boilers, ensuring that they remain a cornerstone of the beverage industry's operations. Whether it's a refreshing soda, a steaming cup of coffee, or a fine glass of wine, the unseen hand of a well-engineered steam boiler is ever-present, quietly crafting the beverages we love.

steam boiler for beverages manufacturers. The steam's latent heat provides an efficient and cost-effective method for maintaining optimal temperatures in the plant, contributing to overall energy efficiency.

For manufacturers, choosing the right steam boiler is a strategic decision. Factors such as capacity, efficiency, fuel type, and automation level all influence the effectiveness of the boiler in meeting the specific demands of the beverage production process. Modern boilers, with their advanced controls and high thermal efficiency, offer not only reliability but also environmental benefits through reduced emissions.

In conclusion, steam boilers are more than just machinery; they are integral components in the intricate dance of beverage manufacturing. Their role is pivotal, shaping the taste, safety, and quality of the beverages we enjoy daily. As technology advances, so too does the functionality and efficiency of steam boilers, ensuring that they remain a cornerstone of the beverage industry's operations. Whether it's a refreshing soda, a steaming cup of coffee, or a fine glass of wine, the unseen hand of a well-engineered steam boiler is ever-present, quietly crafting the beverages we love.

In addition to these direct applications, steam boilers also power various ancillary equipment in a beverage plant, such as pumps, conveyor systems, and heating systems for water and cleaning solutions

In addition to these direct applications, steam boilers also power various ancillary equipment in a beverage plant, such as pumps, conveyor systems, and heating systems for water and cleaning solutions

In addition to these direct applications, steam boilers also power various ancillary equipment in a beverage plant, such as pumps, conveyor systems, and heating systems for water and cleaning solutions

In addition to these direct applications, steam boilers also power various ancillary equipment in a beverage plant, such as pumps, conveyor systems, and heating systems for water and cleaning solutions steam boiler for beverages manufacturers. The steam's latent heat provides an efficient and cost-effective method for maintaining optimal temperatures in the plant, contributing to overall energy efficiency.

For manufacturers, choosing the right steam boiler is a strategic decision. Factors such as capacity, efficiency, fuel type, and automation level all influence the effectiveness of the boiler in meeting the specific demands of the beverage production process. Modern boilers, with their advanced controls and high thermal efficiency, offer not only reliability but also environmental benefits through reduced emissions.

In conclusion, steam boilers are more than just machinery; they are integral components in the intricate dance of beverage manufacturing. Their role is pivotal, shaping the taste, safety, and quality of the beverages we enjoy daily. As technology advances, so too does the functionality and efficiency of steam boilers, ensuring that they remain a cornerstone of the beverage industry's operations. Whether it's a refreshing soda, a steaming cup of coffee, or a fine glass of wine, the unseen hand of a well-engineered steam boiler is ever-present, quietly crafting the beverages we love.

steam boiler for beverages manufacturers. The steam's latent heat provides an efficient and cost-effective method for maintaining optimal temperatures in the plant, contributing to overall energy efficiency.

For manufacturers, choosing the right steam boiler is a strategic decision. Factors such as capacity, efficiency, fuel type, and automation level all influence the effectiveness of the boiler in meeting the specific demands of the beverage production process. Modern boilers, with their advanced controls and high thermal efficiency, offer not only reliability but also environmental benefits through reduced emissions.

In conclusion, steam boilers are more than just machinery; they are integral components in the intricate dance of beverage manufacturing. Their role is pivotal, shaping the taste, safety, and quality of the beverages we enjoy daily. As technology advances, so too does the functionality and efficiency of steam boilers, ensuring that they remain a cornerstone of the beverage industry's operations. Whether it's a refreshing soda, a steaming cup of coffee, or a fine glass of wine, the unseen hand of a well-engineered steam boiler is ever-present, quietly crafting the beverages we love. Latest news

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.15,2025

-

Leading Electric Steam Boiler Manufacturers for IndustryNewsAug.14,2025

-

Buy Waste Heat Boilers: Custom, Efficient & Affordable SolutionsNewsAug.13,2025

-

Electric Steam Boiler Manufacturers | Industrial Power & EfficiencyNewsAug.12,2025

-

Electric Steam Boiler Manufacturers: Efficient & Reliable SolutionsNewsAug.11,2025

-

China Steam Boiler Price: Efficient Industrial Systems & BurnersNewsAug.10,2025