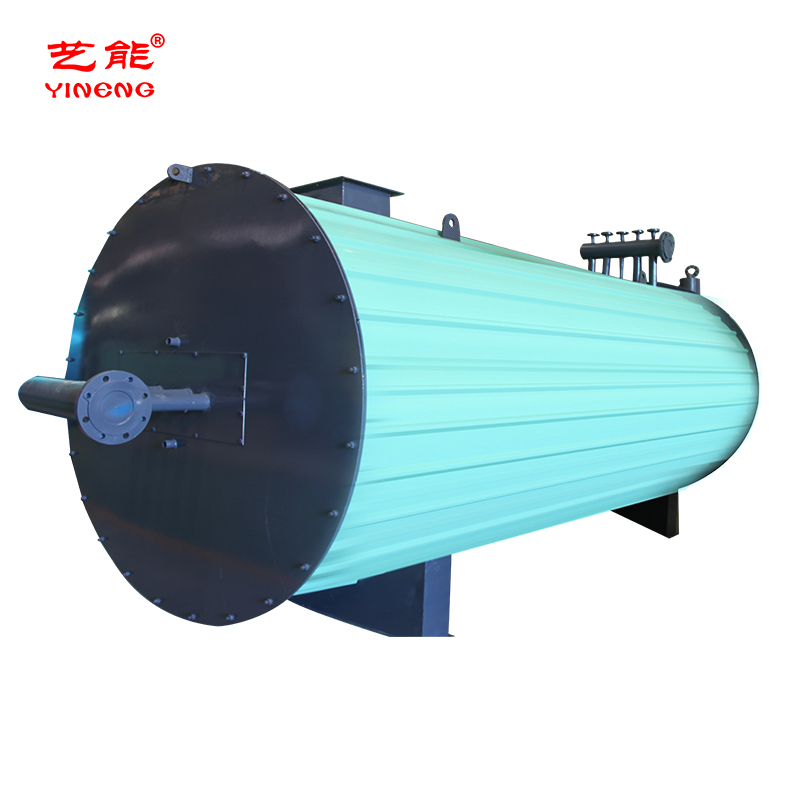

steam boiler for garment factory factories

The Importance of Steam Boilers in Garment Factories

In the bustling world of garment manufacturing, efficient operations are paramount. One of the pivotal components that underpin these operations is the steam boiler. Steam boilers play an essential role in garment factories, providing the necessary heat and steam required for various processes such as washing, dyeing, and finishing fabrics. This article delves into the significance of steam boilers in garment factories, highlighting their functionality, benefits, and impact on productivity and sustainability.

Understanding Steam Boilers

A steam boiler is a vessel designed to generate steam from water by applying heat energy. In garment factories, steam is crucial for several processes. The most common types of steam boilers used are fire-tube and water-tube boilers, each with its operational characteristics and efficiencies. Fire-tube boilers are known for their simple design and easy maintenance, while water-tube boilers are preferred for their high efficiency and capability to produce steam at varying pressures.

Role of Steam Boilers in Garment Manufacturing

1. Fabric Processing One of the primary uses of steam in the garment industry is in fabric processing. Steam is utilized in washing fabrics, where it helps remove impurities, dyes, and chemicals from the fabric surface. High-pressure steam also plays a vital role in the dyeing process, where it helps achieve uniform coloring and fast dye fixation, crucial for producing high-quality garments.

2. Finishing Processes After manufacturing, garments undergo various finishing processes to enhance their appearance and durability. Steam is essential in pressing and finishing, where it helps eliminate wrinkles and gives fabrics a crisp, professional look. This process not only improves the aesthetic quality of the garments but also increases their market value.

3. General Operations Beyond specific garment processes, steam boilers contribute to general factory operations. They provide the necessary heat for space heating in factories, ensuring a comfortable working environment for employees. Moreover, steam serves as a power source for various machines, enhancing operational efficiency.

Benefits of Using Steam Boilers

steam boiler for garment factory factories

Investing in a steam boiler system can yield numerous benefits for garment factories.

- Energy Efficiency Modern steam boilers are engineered to be highly efficient, utilizing energy resources effectively and reducing fuel consumption. This efficiency translates into lower operational costs, significantly impacting a factory's bottom line.

- Sustainability As the garment industry faces increasing scrutiny over its environmental impact, steam boilers provide an opportunity for factories to adopt cleaner technologies. Many contemporary boilers can use renewable energy sources, such as biomass, thereby reducing greenhouse gas emissions and aligning with global sustainability goals.

- Reliability and Consistency Maintaining a consistent steam supply is crucial for ensuring uninterrupted operations in garment factories. Reliable steam boilers can support continuous production, minimizing downtime and enhancing productivity.

Challenges and Considerations

While steam boilers offer numerous advantages, they also come with challenges. Factories must carefully consider the size and type of boiler that will best meet their needs. Oversized boilers can lead to inefficiencies and higher costs, while undersized units may struggle to meet production demands. Additionally, the installation and maintenance of steam boiler systems require expert knowledge to ensure safety and optimal performance.

Moreover, as steam systems can be responsible for significant energy consumption, garment factories must regularly monitor their systems for maintenance and upgrades. Implementing regular inspections and ensuring compliance with safety regulations is critical to avoid accidents and ensure long-term operational success.

Conclusion

In conclusion, steam boilers are a cornerstone of efficient garment manufacturing. They facilitate essential processes, enhance productivity, and promote sustainability within the industry. As garment factories continue to evolve and face new challenges, investing in advanced steam boiler systems will be paramount. By embracing innovation and efficiency, garment manufacturers can not only improve their production capabilities but also contribute to a greener and more sustainable future in fashion.

-

Top Electric Steam Boiler Manufacturers | AI EfficiencyNewsAug.04,2025

-

Efficient Thermal Oil Boilers with AI Optimization | Superior PerformanceNewsAug.03,2025

-

High-Efficiency OEM Steam Boilers w/GPT-4-TurboNewsAug.02,2025

-

Advanced Electric Steam Boiler Manufacturers | GPT-4 Turbo AINewsAug.01,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025