steam boiler for garment factory pricelist

Understanding Steam Boiler Prices for Garment Factories

The garment industry is a vital sector that significantly contributes to the economy worldwide. An essential element of this industry is the steam boiler, which plays a crucial role in various processes such as fabric conditioning, dyeing, and finishing. For garment factories looking to acquire a steam boiler, understanding the pricing and factors influencing costs is integral in making a well-informed purchasing decision.

Factors Influencing Steam Boiler Prices

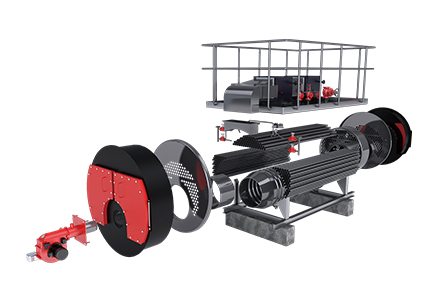

1. Type of Boiler There are different types of steam boilers, such as fire-tube, water-tube, and electric boilers, each with unique features and applications. Fire-tube boilers are typically more suitable for small to medium-sized operations, while water-tube boilers are commonly used in larger industrial applications. The choice of boiler directly impacts the price.

2. Capacity The boiler’s capacity, measured in tons, determines its output and the amount of steam it can generate per hour. Garment factories will need to consider their production needs to select an appropriately sized boiler. Higher capacity models generally come with a larger price tag.

3. Fuel Type Steam boilers can operate using different fuel sources such as natural gas, oil, biomass, or electricity. The choice of fuel affects both the initial investment and operational costs. For instance, gas boilers tend to be more energy-efficient but could have higher installation costs.

4. Brand and Quality The brand and the quality of materials used in the construction of the boiler are significant factors influencing price. Reputable manufacturers with a history of reliability and performance may charge a premium, but the investment often pays off in terms of longevity and reduced maintenance costs.

steam boiler for garment factory pricelist

5. Additional Features Advanced features like automation, efficiency controls, and safety systems can enhance the functionality of steam boilers. While these features can increase the initial cost, they may lead to long-term savings and improved productivity.

Impacts on Operational Costs

In addition to the initial purchase price, garment factories must consider the operational costs associated with running a steam boiler. These include fuel costs, maintenance, labor, and water treatment expenses. A more energy-efficient boiler may have a higher upfront cost but can lead to lower operational expenses over time, enhancing overall profitability.

Price Ranges

Steam boiler prices can vary significantly based on the aforementioned factors. For example, small fire-tube boilers might range from $5,000 to $20,000, while larger, more complex water-tube boilers can cost anywhere from $20,000 to $150,000, or even more for custom designs. Conducting thorough research and obtaining multiple quotes from different manufacturers can help garment factories find the best deals tailored to their specific needs.

Conclusion

Acquiring a steam boiler is a considerable investment for any garment factory. By understanding the factors influencing boiler prices and considering the long-term operational implications, manufacturers can make informed decisions that align with their production goals and budgets. Ultimately, the right steam boiler not only enhances productivity but also contributes to the overall efficiency and sustainability of textile manufacturing processes. Investing time in evaluating options will ensure that garment factories are equipped with the best machinery to meet their production demands.

-

Leading Electric Steam Boiler Manufacturers for IndustryNewsAug.06,2025

-

Top Electric Steam Boiler Manufacturers | AI EfficiencyNewsAug.04,2025

-

Efficient Thermal Oil Boilers with AI Optimization | Superior PerformanceNewsAug.03,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025