Industrial Steam Boiler Suppliers for Efficient Energy Solutions and Reliable Performance

Understanding the Significance of Steam Boilers in Industries

In various industrial sectors, steam boilers are pivotal in facilitating processes that require thermal energy. These equipment pieces generate steam, which is extensively utilized in power generation, heating, and various industrial applications. With an increasing demand for efficient and sustainable energy sources, the role of steam boilers has become even more crucial. This article explores the significance of steam boilers in industries, the types available, and the qualities to look for in a steam boiler supplier.

The Role of Steam Boilers in Industries

Steam boilers function by converting water into steam through the application of heat. This steam is then used for numerous applications including heating facilities, driving turbines for electricity generation, and powering machinery in manufacturing processes. Industries such as food processing, pharmaceuticals, textiles, chemicals, and paper production rely heavily on steam for their operational efficiency.

In the food processing industry, for instance, steam is essential for cooking and sterilization processes. In pharmaceuticals, it sterilizes equipment and materials, ensuring the safety and effectiveness of products. Additionally, in power plants, steam boilers produce steam that drives turbines for electricity generation, contributing to the overall energy grid.

Types of Steam Boilers

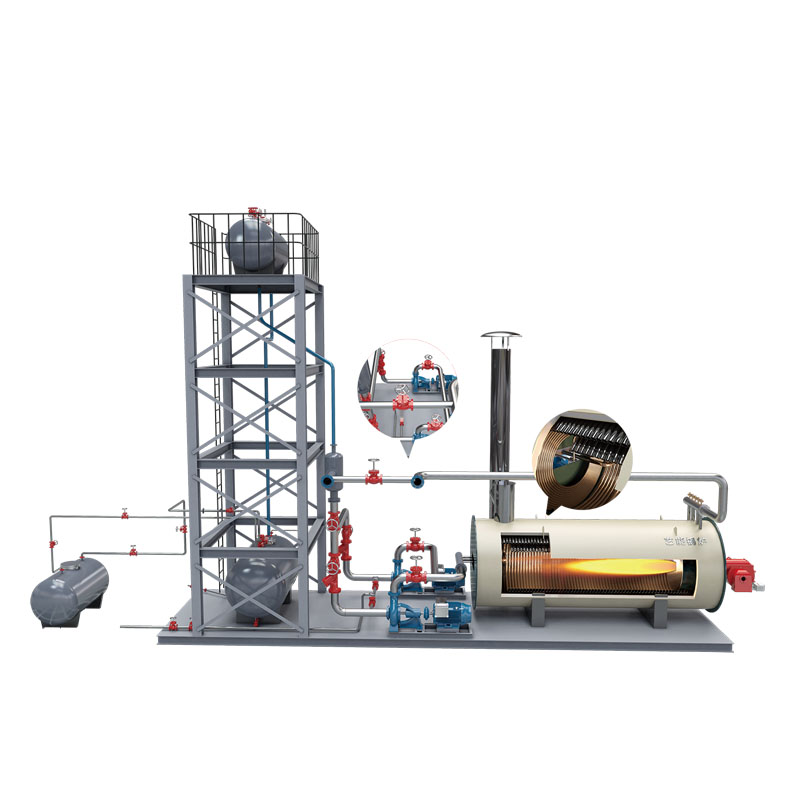

There are several types of steam boilers, each designed to meet specific industry requirements. The most common types include

1. Fire-Tube Boilers These are compact and simple in design, where hot gases from the combustion process pass through tubes surrounded by water. They are generally used for lower pressure and lower output applications.

2. Water-Tube Boilers In contrast, water-tube boilers have water circulating in tubes that are heated by surrounding hot gases. They are better suited for high-pressure and high-capacity applications due to their ability to withstand higher pressures and provide quicker steam generation.

3. Electric Boilers These utilize electric heating elements to generate steam and are particularly advantageous in places where electricity is cheaper or more readily available than fuel.

steam boiler for industry supplier

Choosing a Reliable Steam Boiler Supplier

Selecting a reliable steam boiler supplier is crucial for the longevity and efficiency of boiler systems. Here are some characteristics to consider when evaluating potential suppliers

1. Experience and Expertise Look for a supplier with a solid track record in the industry. An experienced supplier will understand the unique requirements of your industry and provide tailored solutions.

2. Quality of Products Reputable suppliers maintain high manufacturing standards and offer certified products. It’s essential to check for compliance with relevant industry standards and certifications.

3. Customer Support and Service A good supplier should provide excellent customer support including installation, maintenance, and repair services. Their after-sales service can significantly impact the lifespan and efficiency of your steam boiler.

4. Customization Options Every industry has specific requirements; hence, a supplier that offers customization options can provide you with a boiler that meets your exact needs.

5. References and Reviews Positive testimonials and case studies from previous clients can help gauge the reliability and performance of a supplier.

Conclusion

Steam boilers are a cornerstone of many industrial processes, providing essential thermal energy for operations. As industries evolve towards more energy-efficient and sustainable practices, the importance of steam boilers is likely to increase. Choosing the right supplier is crucial for ensuring that your operations run smoothly and efficiently. By focusing on quality, experience, and support, industries can ensure they have the best steam boiler systems in place to meet their needs and drive productivity. Investing in quality steam boilers and a dependable supplier is not just a choice; it is a strategic move towards efficiency and sustainability in industrial operations.

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025

-

High-Efficiency Thermal Oil Boiler for Industrial Heating SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers for Industrial EfficiencyNewsJul.28,2025