Steam Boiler Solutions for Efficient Paper Plant Operations and Production

Steam Boiler for Paper Plant Production

The paper industry is one of the most significant sectors in the global economy, producing essential materials used in various applications, from packaging to publishing. Within this industry, steam boilers play a crucial role in the manufacturing process, providing the thermal energy required for various operations. The functionality, efficiency, and reliability of steam boilers are imperative for the paper production line's overall effectiveness. This article explores the salient aspects of steam boilers specifically tailored for paper plants, highlighting their importance, operational mechanics, and benefits.

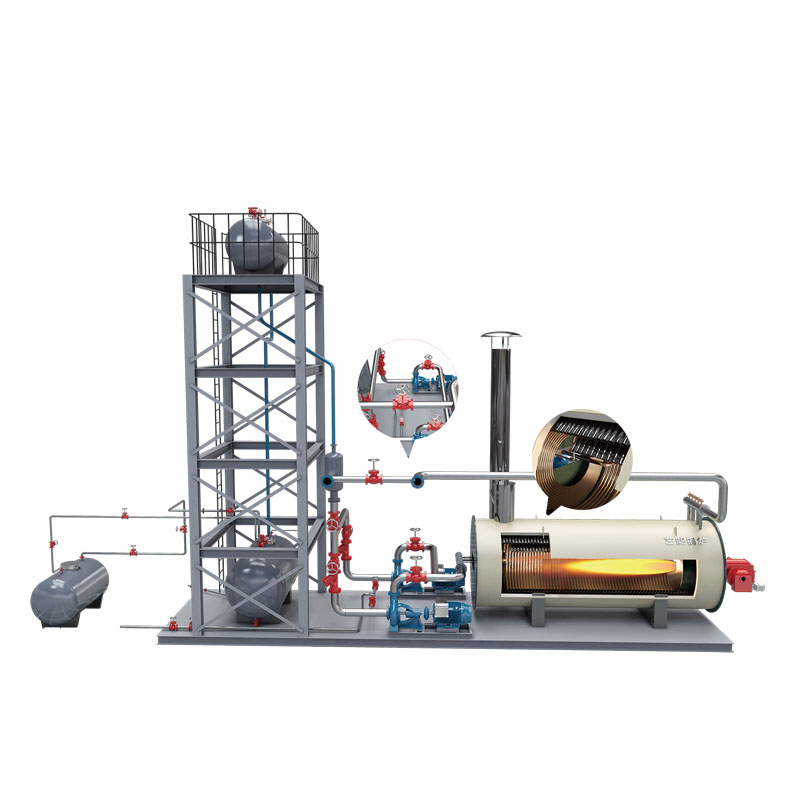

Understanding Steam Boilers

Steam boilers are closed vessels that convert water into steam through the application of heat. In the context of a paper plant, these boilers are integral to the production workflow, supplying steam for multiple processes, including pulping, drying, and pressing. The steam generated is utilized in different stages, such as heating the pulp to facilitate chemical reactions and drying the paper sheets before they are cut and packaged.

The Role of Steam in Paper Production

The pulp and paper production process involves various steps, each requiring substantial amounts of energy. Steam plays a vital role in maintaining the quality and efficiency of these processes. For example, during the pulping phase, steam is used to soften wood chips, thereby breaking down the lignin that binds the fibers together. This allows for better fiber separation and results in higher quality pulp.

In addition to pulping, steam is critical during the drying process. After the pulp is converted into sheets, it contains a significant amount of moisture. Steam is used to heat drying rollers or cylinders, allowing the moisture to evaporate effectively. This process not only enhances the paper quality but also reduces the risk of defects resulting from uneven drying.

Types of Steam Boilers Used in Paper Plants

There are several types of steam boilers utilized in paper production facilities

. The most common includesteam boiler for paper plant product

1. Fire-Tube Boilers These are widely favored in paper plants due to their simple design and ease of operation. In fire-tube boilers, hot gases produced from fuel combustion pass through tubes submerged in water, transferring heat and generating steam.

2. Water-Tube Boilers These are typically used for larger operations where high pressure and large steam quantities are necessary. In water-tube boilers, water flows through tubes heated by the combustion gases, allowing for higher steam generation capabilities and efficiency.

3. Packaged Boilers Designed for ease of installation and operation, packaged boilers offer a compact solution for smaller paper plants. They come as complete units that can be easily transported and set up on-site.

Efficiency and Sustainability

In today’s eco-conscious world, the paper industry faces increasing pressure to adopt sustainable practices. Modern steam boilers have evolved to enhance energy efficiency and reduce emissions. These advancements allow paper plants to optimize energy use, recycle heat, and minimize waste.

Condensate recovery systems are commonly integrated into steam boiler setups to capture and reuse excess steam. This not only conserves water but also significantly reduces energy costs. Furthermore, advancements in boiler technology, such as modular designs and automated controls, enable real-time monitoring and adjustment, ensuring optimal performance and minimal energy use.

Conclusion

The steam boiler is a cornerstone of production in the paper industry, enabling efficient processing and high-quality output. As the industry continues to evolve, the focus on sustainability and energy efficiency will drive innovation in steam boiler design and operation. By investing in modern steam boiler technology, paper plants can not only enhance their production capabilities but also contribute to a more sustainable future. Understanding the vital role these boilers play is essential for anyone involved in the paper production process, from engineers to plant managers, ensuring that they can optimize operations and maintain high standards in an increasingly competitive market.

-

Top Electric Steam Boiler Manufacturers for Industrial EfficiencyNewsJul.28,2025

-

Top Electric Steam Boiler Manufacturers | Industrial Solutions & CustomizationNewsJul.27,2025

-

Top Electric Steam Boiler Manufacturers | Industrial Steam SolutionsNewsJul.26,2025

-

Top Electric Steam Boiler Manufacturers – Reliable Industrial SolutionsNewsJul.25,2025

-

Top Electric Steam Boiler Manufacturers – Reliable Industrial SolutionsNewsJul.24,2025

-

Top Electric Steam Boiler Manufacturers – High Efficiency & ReliabilityNewsJul.23,2025