Jan . 19, 2025 02:48

Back to list

steam boiler for sugar

The steam boiler is an integral component in the sugar industry, playing a crucial role in transforming raw materials into the sweet product we commonly consume. As the global demand for sugar continues to rise, the efficiency and effectiveness of steam boilers become paramount for production sustainability. Understanding the sophisticated nature of these boilers, combined with real-world expertise, is essential for anyone involved in sugar manufacturing.

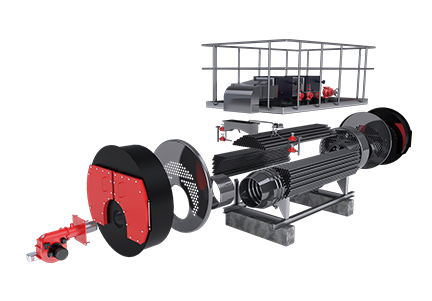

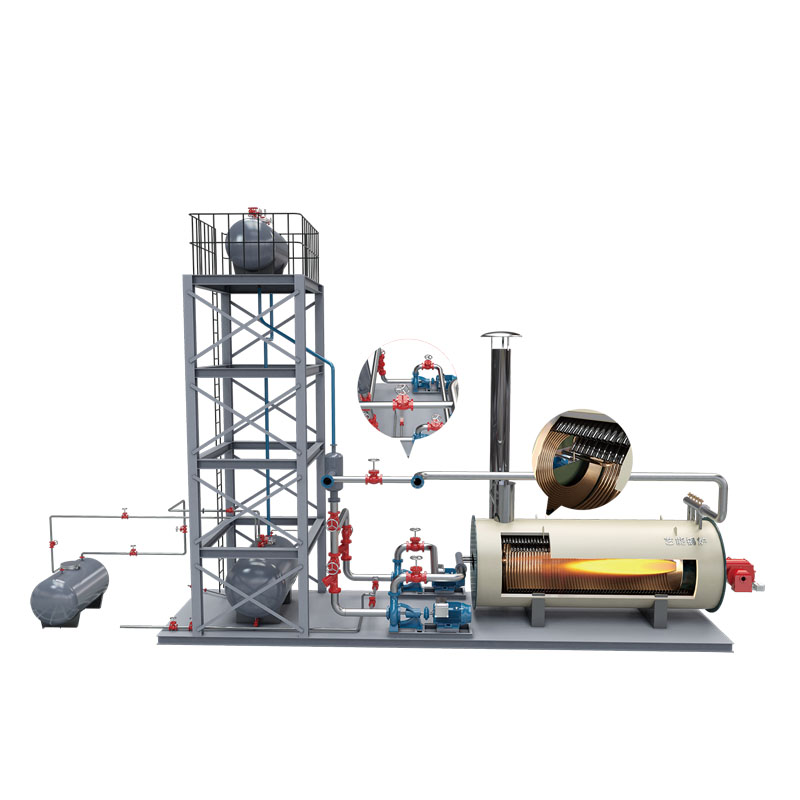

The product choices in steam boilers are diverse, ranging from fire-tube boilers to water-tube boilers. Water-tube boilers are particularly suited for high-pressure demands of sugar milling, providing rapid heat transfer and higher output than their fire-tube counterparts. They also offer superior safety features, with no large-scale water stored in steam drums, which mitigates risks associated with rupture or overheating. Innovation within this field is integral, and companies investing in cutting-edge technologies are often rewarded with higher efficiency and better outputs. For instance, the implementation of fluidized bed combustion technology in boilers can improve combustion efficiency and reduce pollutants, aligning with global drives towards sustainability. Experience highlights that selecting the correct boiler structure isn’t only about immediate performance but also about long-term sustainability and adaptability to future advancements. There's increasing attention towards eco-friendly solutions, with manufacturers focusing on low-emission systems. Adopting these greener technologies not only adheres to burgeoning regulatory requirements but also contributes to a company’s responsibility toward reducing its carbon footprint. In conclusion, understanding the comprehensive functionalities of steam boilers, combined with leveraging insights from experienced professionals, is critical for maximizing the economic and operational efficiencies in sugar production. Choosing the right boiler solution—one that is high-performing, compliant with international standards, reliable, and sustainable—can ensure that sugar manufacturers are not only meeting current demands but are also poised for future growth in an increasingly competitive market.

The product choices in steam boilers are diverse, ranging from fire-tube boilers to water-tube boilers. Water-tube boilers are particularly suited for high-pressure demands of sugar milling, providing rapid heat transfer and higher output than their fire-tube counterparts. They also offer superior safety features, with no large-scale water stored in steam drums, which mitigates risks associated with rupture or overheating. Innovation within this field is integral, and companies investing in cutting-edge technologies are often rewarded with higher efficiency and better outputs. For instance, the implementation of fluidized bed combustion technology in boilers can improve combustion efficiency and reduce pollutants, aligning with global drives towards sustainability. Experience highlights that selecting the correct boiler structure isn’t only about immediate performance but also about long-term sustainability and adaptability to future advancements. There's increasing attention towards eco-friendly solutions, with manufacturers focusing on low-emission systems. Adopting these greener technologies not only adheres to burgeoning regulatory requirements but also contributes to a company’s responsibility toward reducing its carbon footprint. In conclusion, understanding the comprehensive functionalities of steam boilers, combined with leveraging insights from experienced professionals, is critical for maximizing the economic and operational efficiencies in sugar production. Choosing the right boiler solution—one that is high-performing, compliant with international standards, reliable, and sustainable—can ensure that sugar manufacturers are not only meeting current demands but are also poised for future growth in an increasingly competitive market.

Latest news

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025

-

High-Efficiency Thermal Oil Boiler for Industrial Heating SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers for Industrial EfficiencyNewsJul.28,2025

-

Top Electric Steam Boiler Manufacturers | Industrial Solutions & CustomizationNewsJul.27,2025