steam boiler for textile mill supplier

Steam Boiler for Textile Mill Suppliers A Crucial Component for Efficient Production

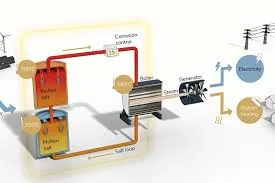

In the textile industry, the efficient and reliable operation of machinery is essential for maintaining productivity and quality. Among the key components that contribute to a smooth manufacturing process is the steam boiler. As a supplier of steam boilers for textile mills, it is vital to understand the specific needs of this sector to ensure optimal performance and energy efficiency.

Steam Boiler for Textile Mill Suppliers A Crucial Component for Efficient Production

One of the significant advantages of modern steam boilers is their efficiency. Suppliers are increasingly offering high-efficiency boilers that consume less fuel, thereby reducing operating costs. These boilers are designed with advanced technology to minimize heat loss and ensure that a maximum amount of energy is converted into steam. In an industry where margins can be tight, the ability to reduce energy consumption is a valuable selling point for suppliers.

steam boiler for textile mill supplier

Moreover, with growing environmental concerns, textile mills are under pressure to adopt sustainable practices. Suppliers must consider environmentally friendly solutions, such as biomass boilers or those that utilize waste heat recovery systems. These alternatives not only help reduce carbon emissions but also promote a more sustainable approach to production. Offering these options can give suppliers a competitive edge in a market that is increasingly leaning towards green technologies.

Furthermore, the reliability of steam boilers is paramount. Downtime due to boiler failures can lead to significant losses in production and revenue. Therefore, suppliers must ensure that they provide not only high-quality products but also excellent after-sales support, including maintenance and repair services. A reputation for reliability can establish long-lasting relationships with textile companies seeking to partner with dependable suppliers.

In conclusion, steam boilers play a vital role in the textile industry, significantly impacting production efficiency and product quality. As a supplier, it is essential to deliver high-efficiency, reliable, and sustainable boiler solutions tailored to the needs of textile mills. Emphasizing quality, customer service, and innovative technologies will position suppliers as leaders in the market. By meeting these demands, suppliers can contribute to the success of textile manufacturers while ensuring their operations remain competitive and sustainable in an ever-evolving industry landscape.

-

Industrial Electric Steam Boiler Manufacturers | Efficient SolutionsNewsAug.08,2025

-

Industrial Electric Steam Boilers | Top Manufacturers & SuppliersNewsAug.07,2025

-

Leading Electric Steam Boiler Manufacturers for IndustryNewsAug.06,2025

-

Top Electric Steam Boiler Manufacturers | AI EfficiencyNewsAug.04,2025

-

Efficient Thermal Oil Boilers with AI Optimization | Superior PerformanceNewsAug.03,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025