steam boiler industry pricelist

Understanding the Steam Boiler Industry Price List

The steam boiler industry is a vital sector within the infrastructure and energy landscape, playing a crucial role in various applications ranging from power generation to industrial processes. As industries evolve and demand fluctuates, understanding the pricing dynamics within this industry becomes essential for businesses, engineers, and procurement specialists. This article delves into the factors influencing steam boiler pricing and provides insights into interpreting industry price lists.

Factors Influencing Steam Boiler Prices

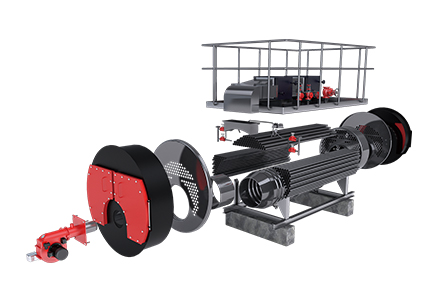

1. Type of Boiler The price of steam boilers varies significantly based on their type. For instance, fire-tube boilers tend to be less expensive compared to water-tube boilers due to their simpler construction and lower material costs. Additionally, specialty boilers, such as those designed for high-pressure applications or specific environmental standards, may command a premium due to their advanced technology and engineered specifications.

2. Capacity and Size The boiler's capacity, measured in BTUs (British Thermal Units) or horsepower, is a major determinant of price. Larger boilers capable of generating more steam to accommodate high-demand applications typically come with higher price tags. Companies must evaluate their operational needs carefully to ensure they choose a model that balances cost and efficiency.

3. Fuel Type Different boilers operate on various fuels—natural gas, oil, biomass, or coal—each with its associated costs. The availability and pricing of these fuels can also affect boiler costs. For instance, natural gas boilers may be more economical and environmentally friendly in certain regions compared to coal-fired options, which might face stringent regulations.

4. Material Quality The materials used in constructing steam boilers can significantly influence their price. High-grade steel or alloy components that provide durability and enhance efficiency often lead to higher upfront costs. However, investing in quality materials can lead to long-term savings in terms of operational efficiency and reduced maintenance needs.

5. Technological Advancements Modern steam boilers often incorporate advanced technologies that improve efficiency, reduce emissions, and enhance safety features. While these high-tech boilers may have higher initial costs, they can lead to substantial savings in fuel and operational costs over time. Therefore, when reviewing price lists, it’s important to consider the long-term benefits of technology investments.

steam boiler industry pricelist

6. Market Demand and Economic Factors The overall demand for steam boilers in various industries, coupled with global economic conditions, can cause price fluctuations. A sudden increase in demand, such as during a manufacturing boom or energy crisis, can drive prices up, while an economic downturn may lead to reduced prices. Keeping abreast of market trends is crucial for making informed purchasing decisions.

Interpreting the Industry Price List

When examining the steam boiler industry price list, several key aspects should be considered

- Comprehensive Listings Look for vendors that provide detailed price lists featuring all boiler models, specifications, and capacities. This transparency helps in comparing options and ensuring you are getting the best value.

- Additional Costs Understand that the listed price may not be the total cost. Additional expenses such as installation, maintenance contracts, and operating costs should also be factored in.

- Warranty and After-Sales Support Price lists should also indicate warranty periods and the level of customer support provided. Robust after-sales support can save significant time and money in managing potential issues post-purchase.

Conclusion

In conclusion, understanding the steam boiler industry price lists involves more than just looking at upfront costs. By considering various factors influencing price, such as type, capacity, fuel, material quality, technology, and market conditions, stakeholders can make more informed decisions. This holistic approach not only aids in budget management but also fosters long-term operational efficiency and sustainability within industries reliant on steam boilers. As the global demand for energy-efficient solutions continues to rise, staying informed about pricing trends and technological advancements will be paramount for all involved in this essential industry.

-

High-Efficiency OEM Steam Boilers w/GPT-4-TurboNewsAug.02,2025

-

Advanced Electric Steam Boiler Manufacturers | GPT-4 Turbo AINewsAug.01,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025