Thermal Oil Boiler — Efficient, Precise, Low-Pressure Heat

Thermal Oil Boiler is a key solution in the Mechanical equipment manufacturing industry, specifically within Manufacturing of boilers and auxiliary equipment and Manufacturing of fuel (gas) heat carrier furnace. This article explores how Hebei Yineng Boiler Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Thermal Oil Boiler Overview

- Benefits & Use Cases of Thermal Oil Boiler in Manufacturing of fuel (gas) heat carrier furnace

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Mechanical equipment manufacturing

- Conclusion on Thermal Oil Boiler from Hebei Yineng Boiler Co., Ltd

Thermal Oil Boiler Overview

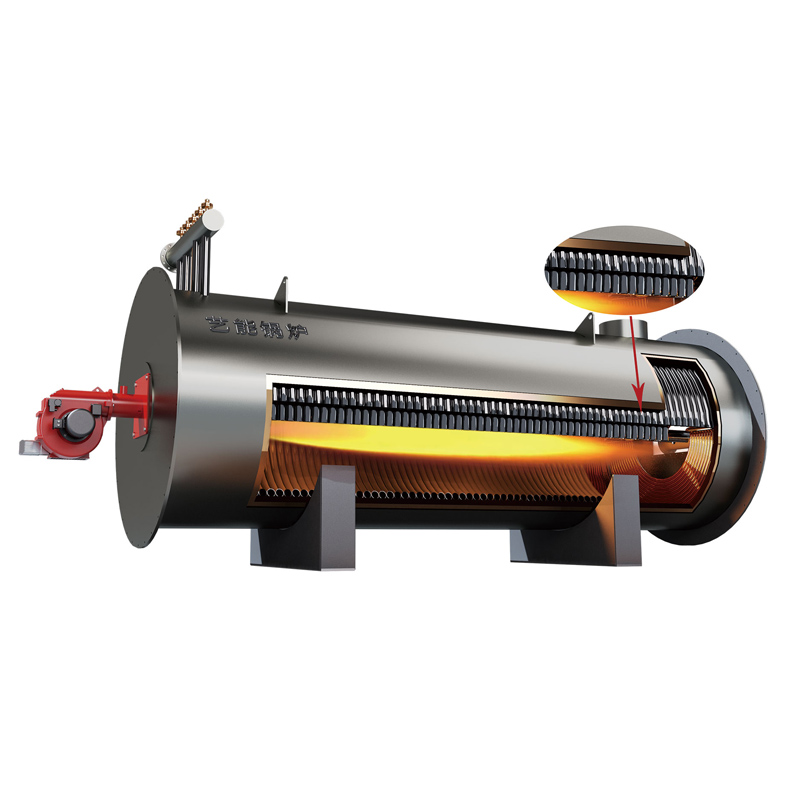

A Thermal Oil Boiler—also called a heat carrier furnace—uses high-stability heat transfer oil instead of water or steam to deliver precise process temperatures at comparatively low system pressures. For B2B operations in Mechanical equipment manufacturing and the Manufacturing of boilers and auxiliary equipment, this translates into safer operation, tighter temperature control (often in the 150–350°C range), and fewer constraints related to water treatment or steam traps. Hebei Yineng Boiler Co., Ltd’s YQW/YQL series gas or diesel oil-fired models combine a compact coil design with forced circulation to minimize temperature gradients and extend oil life, making them a reliable backbone for continuous-duty lines.

- Relevance: In the Manufacturing of fuel (gas) heat carrier furnace segment, a boiler thermal oil heater provides steady, uniform heat for curing, drying, and reactor jacket processes with lower operational risk versus steam at equivalent temperatures.

- Technical background: Multi-pass coil arrangement, high-efficiency burner matching, and PLC-based controls form a robust thermal oil system that supports precise setpoints and smooth ramping. Optional expansion tanks, deaerators, and filtration extend oil life and reduce fouling.

- Trusted supplier: Hebei Yineng Boiler Co., Ltd delivers engineered solutions, OEM boiler thermal oil customization, and pre-piped skid options to streamline installation and accelerate start-up.

Benefits & Use Cases of Thermal Oil Boiler in Manufacturing of fuel (gas) heat carrier furnace

In gas-fired heat carrier furnace manufacturing, the Thermal Oil Boiler is the core heat source that stabilizes downstream processes such as continuous ovens, drying tunnels, bitumen melters, wood-based panel presses, calendering lines, and chemical reactor jackets. Hebei Yineng’s solutions integrate seamlessly with pumps, expansion vessels, and control valves to form a closed-loop thermal oil system that mitigates oxidation, maintains film temperature, and prevents hot spots. Compared with steam, users gain faster start-up, greatly reduced scaling/corrosion issues, and the ability to run high-temperature processes at lower pressure—ideal for quality-critical production environments.

- Applications: Coating and printing lines, polymer and resin manufacturing, asphalt and bitumen processing, textiles, food drying, and building materials benefit from stable 24/7 heat delivery.

- Competitive advantages: High turndown burners for load swings, three-pass coil geometry for high heat transfer, and intelligent safety interlocks improve uptime and product quality. Horizontal and vertical footprints increase layout flexibility.

- Sector expertise: Hebei Yineng Boiler Co., Ltd offers oem boiler thermal oil engineering, including customized heat loads, control logic, and skid-mounted modules that reduce site work and commissioning risk.

Cost, Maintenance & User Experience

Total cost of ownership for a Thermal Oil Boiler hinges on fuel efficiency, oil life, and maintenance simplicity. By eliminating water chemistry programs and steam-side equipment, operators often lower operating expenditures while improving temperature accuracy. Hebei Yineng’s engineered coil design, burner pairing, and insulation reduce stack and radiant losses. For maintenance, routine oil sampling (acidity, viscosity), strainer cleaning, burner tuning, and instrument calibration preserve performance and prevent varnish or coking. Customers in the Manufacturing of boilers and auxiliary equipment segment report higher uptime, improved product consistency, and easier operator training thanks to PLC interfaces and alarm logic tailored to their line conditions.

- TCO & ROI: Reduced scaling/corrosion risk, fewer moving parts than steam systems, and long oil replacement cycles support attractive payback—especially where precise high-temperature heat is needed.

- Serviceability: Access doors, modular skid layout, and remote diagnostics streamline inspections and minimize downtime. Hebei Yineng supports commissioning, spare parts, and operator training to safeguard lifecycle value.

Sustainability & Market Trends in Mechanical equipment manufacturing

Tightening emissions regulations and rising energy costs are reshaping process-heat decisions across Mechanical equipment manufacturing. Thermal oil technology aligns well with these trends: low-pressure operation elevates safety, precise temperature control improves yield, and advanced burners with oxygen trim and VFD-driven pumps cut fuel consumption and NOx. Many facilities are also exploring waste heat utilization, hybridization, and alternative fuels to meet corporate decarbonization goals. Hebei Yineng Boiler Co., Ltd proactively supports these pathways with configurable controls, low-NOx burner options, and system-level optimization to reduce energy intensity without sacrificing throughput or quality.

- Market direction: Increased demand for data-driven maintenance, digital integration (SCADA/DCS), and heat recovery solutions in high-temperature lines.

- Forward-thinking partner: Hebei Yineng embeds sustainability-by-design—efficient coil geometry, optimized combustion, and intelligent controls—helping customers future-proof investments and meet evolving compliance standards.

Conclusion on Thermal Oil Boiler from Hebei Yineng Boiler Co., Ltd

For manufacturers seeking stable, high-temperature heat with low system pressure, the Thermal Oil Boiler stands out as a dependable, efficient choice. In Mechanical equipment manufacturing—and especially in the Manufacturing of boilers and auxiliary equipment and Manufacturing of fuel (gas) heat carrier furnace—Hebei Yineng Boiler Co., Ltd delivers robust engineering, configurable controls, and OEM boiler thermal oil customization that accelerates deployment and maximizes uptime. Partner with a supplier that understands your process demands and lifecycle goals. Contact us: email: leesonzhou@aliyun.com. Visit our website: https://www.ynboilers.com

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025