Thermal Oil Boiler - High Efficiency, Low Pressure OEM

thermal oil boiler,boiler thermal oil,thermal oil system,oem boiler thermal oil is a key solution in the Mechanical equipment manufacturing industry, specifically within Manufacturing of boilers and auxiliary equipment and Manufacturing of fuel (gas) heat carrier furnace. This article explores how Hebei Yineng Boiler Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- thermal oil boiler,boiler thermal oil,thermal oil system,oem boiler thermal oil Overview

- Benefits & Use Cases of thermal oil boiler,boiler thermal oil,thermal oil system,oem boiler thermal oil in Manufacturing of fuel (gas) heat carrier furnace

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Mechanical equipment manufacturing

- Conclusion on thermal oil boiler,boiler thermal oil,thermal oil system,oem boiler thermal oil from Hebei Yineng Boiler Co., Ltd

thermal oil boiler,boiler thermal oil,thermal oil system,oem boiler thermal oil Overview

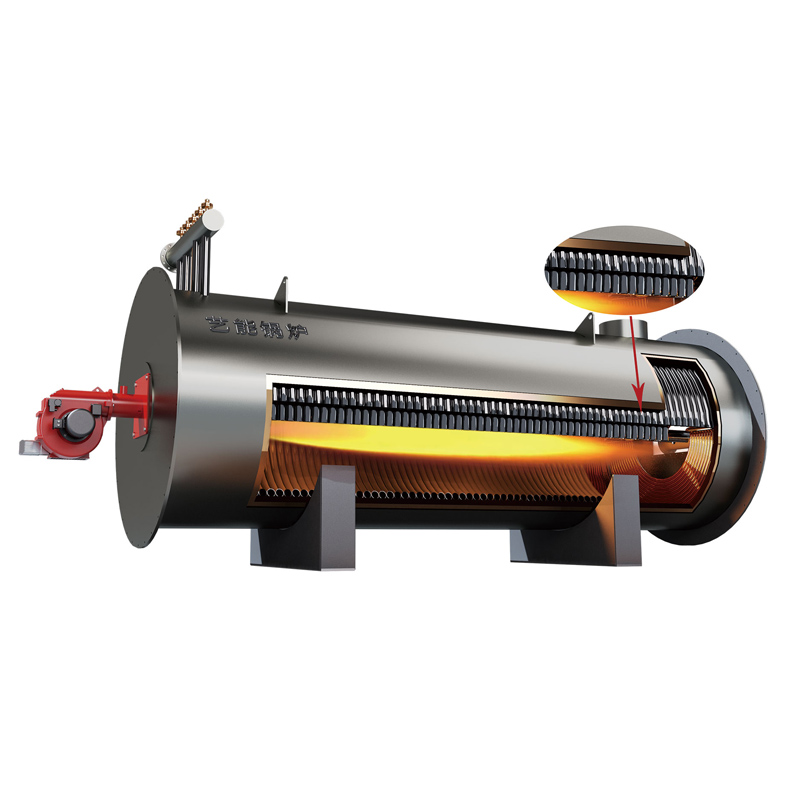

A thermal oil boiler—also called a boiler thermal oil heater or hot oil heater—is engineered to deliver high-temperature heat transfer (typically up to 320–350°C) at comparatively low system pressure. This makes a modern thermal oil system a safe, efficient alternative to steam for process heating across continuous production lines. Hebei Yineng Boiler Co., Ltd designs and manufactures horizontal/vertical YQW/YQL gas or diesel oil–fired units that feature coil-type, multi-pass heat exchange, forced circulation, and precise temperature control for demanding industrial duty.

Yineng’s solutions integrate burners, coils, expansion/deaeration tanks, circulation pumps, control panels, and safety interlocks as a complete package. The oem boiler thermal oil configurations can be customized for capacity, fuel type, layout constraints, and control philosophy (PLC/SCADA). Typical design highlights include high thermal efficiency with optimized flue-gas paths, fast heat-up, and accurate film temperature management to protect the heat transfer medium. Backed by rigorous fabrication and testing standards, Hebei Yineng Boiler Co., Ltd delivers reliable uptime for manufacturers who need stable, uniform heat without the complexity of steam treatment.

Benefits & Use Cases of thermal oil boiler,boiler thermal oil,thermal oil system,oem boiler thermal oil in Manufacturing of fuel (gas) heat carrier furnace

In the Manufacturing of fuel (gas) heat carrier furnace segment, a thermal oil system excels wherever precise, consistent heat is essential. Typical applications include drying and curing ovens, laminating lines, asphalt/bitumen heating, reactors in chemicals and resins, textile dyeing and finishing, food processing, MDF/wood-based panels, and plastics/rubber processing. Compared with steam, boiler thermal oil technology minimizes scaling and water treatment demands, while maintaining stable temperatures across multiple zones and long piping runs.

Hebei Yineng Boiler Co., Ltd optimizes designs for low pressure operation, high turndown burners, and responsive PID control to hold setpoints tightly and reduce product defects. The coil-type heater ensures rapid heat transfer and low flue-gas losses, while optional economizers and air-preheaters further improve fuel economy. OEM boiler thermal oil packages can be engineered for compact footprints, skid-mounting, or integration into existing utilities. With practical service access, intuitive HMIs, and robust safety interlocks, Yineng’s thermal oil boiler line gives B2B decision makers a dependable, scalable platform for process heat in continuous manufacturing.

Cost, Maintenance & User Experience

Total cost of ownership is driven by fuel efficiency, uptime, and maintenance effort. A well-specified thermal oil boiler from Hebei Yineng Boiler Co., Ltd typically delivers notable savings versus steam systems through lower operating pressure, reduced blowdown and water treatment, and less corrosion-related downtime. When combined with heat recovery (e.g., economizers), modern burners, and intelligent control, operators can achieve compelling fuel-use reductions and short payback periods dependent on local energy prices and duty cycles.

Routine maintenance for a thermal oil system focuses on oil quality, burner tuning, and circulation integrity. Recommended practices include periodic hot oil sampling, filtration or top-up, annual inspection of the coil and refractory, seal and pump checks, and verification of safety devices. Customers in the Manufacturing of boilers and auxiliary equipment sector value Yineng’s accessible layouts, spare-parts availability, and remote support options. Reported user experience highlights include fast commissioning, stable process temperatures with fewer line stoppages, and simplified upkeep—translating into predictable ROI and long service life.

Sustainability & Market Trends in Mechanical equipment manufacturing

Across Mechanical equipment manufacturing, decarbonization and efficiency mandates are reshaping process heat. Buyers increasingly specify low-NOx burners, advanced combustion control, and waste-heat recovery to meet tightening emissions and energy-intensity targets. Thermal oil boiler solutions support these objectives by operating at low pressure, minimizing water consumption, and enabling precise heat delivery that cuts over-temperature losses and scrap.

Hebei Yineng Boiler Co., Ltd takes a forward-looking approach with designs that support energy audits, metering, and data connectivity for continuous optimization. Options such as combustion air preheaters, economizers, and fuel flexibility (including natural gas or clean liquid fuels) help align projects with regional regulations and corporate ESG goals. As markets adopt digital maintenance and predictive diagnostics, Yineng’s engineering and OEM capabilities position customers to upgrade performance over the lifecycle—balancing compliance, cost, and productivity in an evolving regulatory landscape.

Conclusion on thermal oil boiler,boiler thermal oil,thermal oil system,oem boiler thermal oil from Hebei Yineng Boiler Co., Ltd

A modern thermal oil boiler offers precise, reliable heat at low pressure—ideal for Manufacturing of boilers and auxiliary equipment and for Manufacturing of fuel (gas) heat carrier furnace applications. With efficient combustion, robust coils, and smart controls, Hebei Yineng Boiler Co., Ltd delivers thermal oil system packages that improve uptime and lower operating costs. For tailored oem boiler thermal oil solutions that match your process needs, contact our team today.

Contact us: email: leesonzhou@aliyun.com

Visit our website: https://www.ynboilers.com

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025