Thermal Oil Boiler: Efficient, Safe Industrial Heating Solutions

Introduction to Advanced Thermal Oil Boiler Systems & Industry Trends

In the intricate landscape of industrial process heating, the choice of a heat transfer system significantly impacts operational efficiency, safety, and environmental compliance. Among various solutions, the thermal oil boiler stands out as a highly effective and versatile technology. These systems leverage specialized heat transfer fluids to achieve high operating temperatures at atmospheric or low pressures, making them ideal for a multitude of demanding applications across diverse sectors.

Current industry trends for industrial heating solutions emphasize enhanced energy efficiency, reduced carbon footprints, and advanced automation. Businesses are increasingly seeking solutions that offer superior control, minimal maintenance, and robust reliability. The demand for systems that can integrate seamlessly with existing digital infrastructure and provide real-time performance data is also on the rise. Furthermore, there is a growing push towards utilizing cleaner fuels and optimizing combustion processes to meet stringent environmental regulations. The adoption of advanced materials and manufacturing techniques ensures longer service life and sustained performance under challenging conditions. These trends position the thermal oil system as a key enabler for modern industrial operations, offering a compelling alternative to traditional steam-based heating, especially where high temperatures are required without the associated high pressures and corrosion risks of water/steam.

The Manufacturing Process of a High-Performance Thermal Oil Boiler

The production of a high-quality thermal oil boiler, such as the Horizontal/Vertical type YQW/L gas or diesel oil fired thermal oil boiler heater, involves a meticulous, multi-stage manufacturing process, underpinned by stringent quality control and adherence to international standards. This commitment ensures not only optimal performance but also extended service life and reliability in critical industrial applications.

1. Design and Engineering

Every boiler begins with sophisticated design, leveraging CAD/CAE software to optimize heat transfer, fluid dynamics, and structural integrity. Designs adhere to international codes like ASME, PED (Pressure Equipment Directive), and specific national standards, ensuring compliance and safety.

2. Material Selection and Preparation

High-grade materials are crucial for durability and performance. Key components include seamless steel tubes for heating surfaces (e.g., ASTM A106 Grade B or equivalent, resistant to high temperatures and pressures), and boiler-grade steel plates for the shell and furnace (e.g., P265GH, SA516 Gr.70). Materials undergo thorough inspection for chemical composition and mechanical properties before fabrication. Precise cutting is performed using CNC plasma or laser cutting machines, ensuring accuracy and minimal material waste.

3. Fabrication of Heating Surfaces and Pressure Parts

- Tube Bending and Coiling: Seamless steel tubes are precisely bent and coiled using specialized CNC bending machines to form the helical or serpentine heating surfaces, crucial for efficient heat transfer within the boiler thermal oil system.

- Welding: Automated welding processes, such as submerged arc welding (SAW) and gas tungsten arc welding (GTAW), are predominantly used for critical pressure parts to ensure consistent, high-integrity welds. Manual welding (SMAW, GMAW) is employed for specific joints, all performed by certified welders according to standards like EN ISO 9606.

- Forming: Plate rolling machines are used to form the cylindrical shells and dished ends, which define the boiler's main structure.

4. Assembly and Integration

Individual components, including the furnace, convection sections, headers, and external piping, are assembled into the complete boiler structure. This stage also includes the integration of burners, control panels, safety devices, and insulation layers.

5. Non-Destructive Testing (NDT) and Quality Assurance

Rigorous testing protocols are applied at various stages:

- Radiographic Testing (RT): Critical welds are X-rayed to detect internal flaws.

- Ultrasonic Testing (UT): Used for thickness measurement and defect detection in materials and welds.

- Magnetic Particle Testing (MPT) / Dye Penetrant Testing (DPT): For surface crack detection.

- Hydrostatic Testing: The completed pressure parts are subjected to pressures significantly higher than their operating pressure to confirm structural integrity and leak-tightness.

- Functional Testing: Burner calibration, control system verification, and safety interlocks are tested prior to dispatch.

These tests adhere to international standards such as ISO 3452, ISO 17638, and ISO 17637, ensuring every thermal oil boiler meets global safety and performance benchmarks. The expected service life for a well-maintained industrial thermal oil boiler can exceed 20 years, a testament to robust design and manufacturing.

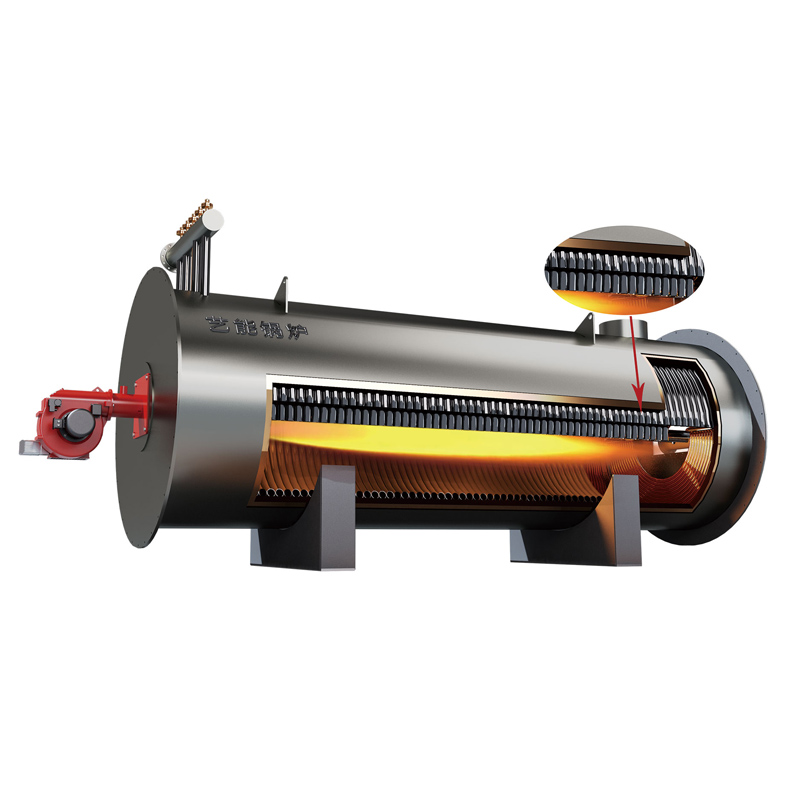

Figure 1: Manufacturing & Assembly of a High-Efficiency Thermal Oil Boiler.

Advantages in Typical Application Scenarios:

- Energy Saving: Superior thermal design and precise temperature control minimize heat loss and optimize fuel consumption, leading to significant energy cost reductions for industries like petrochemicals and textiles. Typical efficiencies can exceed 90%.

- Corrosion Resistance: Unlike water-based systems, thermal oil does not cause scaling or corrosion within the heat exchanger surfaces, extending equipment lifespan and reducing maintenance in sectors such as chemical processing and food manufacturing.

- High Temperature, Low Pressure: Operates at high temperatures (up to 350°C or even higher with specialized fluids) at near-atmospheric pressure, eliminating the need for high-pressure vessels, complex water treatment, and reducing safety risks in industries like plastics and asphalt.

Technical Specifications and Performance Parameters

The Horizontal/Vertical type YQW/L gas or diesel oil fired thermal oil boiler heater is engineered for optimal performance and efficiency across a range of industrial applications. Understanding its technical specifications is crucial for matching the right boiler to specific process requirements. Key parameters define the operational envelope and efficiency profile of these advanced heating units.

Key Technical Terminology Explained:

- Thermal Capacity (kW / kcal/h / MBtu/h): Represents the maximum heat output the boiler can deliver. This is a primary factor in sizing the unit for process demands.

- Max. Operating Temperature (°C): The highest temperature the thermal fluid can safely reach during operation. This dictates suitability for specific high-temperature processes.

- Operating Pressure (MPa): The pressure at which the thermal fluid circulates. A significant advantage of thermal oil systems is their ability to operate at high temperatures under very low or atmospheric pressure, simplifying design and enhancing safety compared to steam boilers.

- Thermal Efficiency (%): The ratio of useful heat output to the total energy input from the fuel. Modern units typically achieve efficiencies well over 90%, due to optimized combustion and heat recovery.

- Fuel Type: Specifies the permissible fuels (e.g., Natural Gas, LPG, Diesel Oil, Heavy Oil). Fuel flexibility is a key advantage for many industrial users.

- Heat Transfer Area (m²): The total surface area through which heat is exchanged from the combustion gases to the thermal oil. A larger area generally indicates higher efficiency and better heat recovery.

Typical Product Specification Table (YQW/L Series)

| Parameter | Unit | Typical Range/Value |

|---|---|---|

| Thermal Capacity | kW / Mcal/h | 350 - 14,000 kW (0.3 - 12 Mcal/h) |

| Max. Operating Temperature | °C | 320 - 350°C |

| Max. Operating Pressure | MPa | 0.8 - 1.0 MPa (Low Pressure) |

| Design Pressure | MPa | 1.2 - 1.6 MPa |

| Thermal Efficiency | % | ≥ 90% (Natural Gas/LPG), ≥ 88% (Diesel Oil) |

| Fuel Type | - | Natural Gas, LPG, Diesel Oil, Light Oil, Heavy Oil |

| Installation Type | - | Horizontal / Vertical (Compact footprint) |

| Burner Type | - | Fully Automatic Combustion (International Brands) |

| Control System | - | PLC-based with Touch Screen HMI |

These specifications highlight the robust engineering and advanced control capabilities designed into these units, ensuring reliable and precise heating for demanding industrial processes. The dual fuel capability (gas or diesel oil) provides significant operational flexibility for regions with varying fuel availability or pricing structures.

Versatile Application Scenarios for Thermal Oil Systems

The inherent advantages of a thermal oil system—primarily high-temperature operation at low pressure and precise temperature control—make it indispensable across a broad spectrum of industries. Its versatility ensures stable and efficient heating for processes where consistent heat is paramount.

Key Target Industries and Their Applications:

- Petrochemical & Chemical Industry: Essential for heating reactors, distillation columns, polymerization processes, and dryers. The precise temperature control prevents product degradation, while the absence of corrosion from thermal oil ensures purity and extends equipment life.

- Oil & Gas Sector: Used for crude oil heating, natural gas processing, asphalt heating, and tank farm heating to maintain viscosity and facilitate pumping, even in extreme cold environments.

- Textile Industry: Provides high-temperature heat for dyeing and printing machines, hot setting, drying processes, and calendering, ensuring consistent product quality and energy efficiency.

- Food & Beverage Processing: Utilized for frying, baking, sterilization, and drying processes where hygienic, consistent, and high-temperature heat is needed without the risk of steam contamination.

- Plastics & Rubber Industry: Crucial for heating presses, molds, extruders, and calendaring machines to ensure uniform curing and shaping of products.

- Timber & Wood Processing: Applied in wood drying kilns, particle board production (hot presses), and laminate manufacturing for consistent heat transfer and product integrity.

- Asphalt & Road Construction: Indispensable for heating asphalt tanks, bitumen storage, and mixing plants to maintain the fluid state and optimize processing temperatures.

- Pharmaceuticals: For drying, sterilization, and reaction heating where precise, clean, and stable temperature control is critical for product quality and safety.

In each of these scenarios, the boiler thermal oil system delivers uniform heat distribution, reduces operational complexities associated with water treatment and blowdown, and offers a safer operating environment due to low-pressure operation. Customer feedback consistently highlights significant reductions in maintenance costs and improved process stability compared to traditional heating methods.

Figure 2: Schematic of a Typical Industrial Thermal Oil System in Operation.

Technical Advantages of Advanced Thermal Oil Boiler Technology

Modern thermal oil boiler systems offer distinct technical advantages that position them as superior heating solutions for various industrial applications, especially when compared to conventional steam or hot water boilers. These benefits translate directly into operational savings, enhanced safety, and greater process control.

1. High Operating Temperatures at Low Pressure:

The most significant advantage is the ability to achieve temperatures up to 350°C (or even higher with synthetic fluids) at near atmospheric pressure. This eliminates the need for expensive, high-pressure vessels, complex safety regulations, and the risks associated with high-pressure steam. It significantly reduces the classification requirements for boiler operators and simplifies plant design.

2. Exceptional Thermal Efficiency:

Utilizing advanced combustion technology and optimized heat transfer surfaces, these boilers achieve thermal efficiencies typically exceeding 90%. Features like economizers (for preheating combustion air or return oil) and advanced insulation further minimize heat loss, leading to substantial fuel savings. The closed-loop nature of a thermal oil system also prevents flash losses and blowdown losses inherent in steam systems.

3. No Corrosion or Scaling:

Since thermal oil is not corrosive and does not involve phase changes (like boiling water), there is no scaling, pitting, or corrosion within the boiler or piping network. This extends the lifespan of the entire heating system, reduces maintenance costs, and eliminates the need for water treatment chemicals and associated effluent disposal.

4. Precise Temperature Control:

Thermal oil systems offer superior temperature control, often within ±1°C, which is critical for sensitive processes in chemical, pharmaceutical, and food industries. The high specific heat capacity of thermal oil allows for stable and uniform heat delivery to the process, improving product quality and consistency.

5. Enhanced Safety Features:

Operating at low pressure inherently reduces safety risks. Modern boilers are equipped with comprehensive safety interlocks, automatic shutdown systems, and advanced flame monitoring. The flash point of quality thermal oils is also significantly high, adding another layer of safety.

6. Lower Operational & Maintenance Costs:

Beyond fuel savings and extended component life, the absence of water treatment, blowdown, and regular steam trap maintenance significantly lowers ongoing operational expenses. Downtime for routine maintenance is also drastically reduced, contributing to higher overall plant productivity.

Vendor Comparison and Customized OEM Solutions

Selecting the right supplier for a thermal oil boiler is as crucial as the technology itself. A thorough vendor comparison should extend beyond initial purchase price to encompass factors like product quality, engineering expertise, after-sales support, and the ability to provide tailored solutions. Many industrial clients seek specialized `oem boiler thermal oil` manufacturers who can integrate heating systems into complex process lines.

Key Factors for Vendor Comparison:

- Certifications and Compliance: Verify adherence to international standards like ISO 9001 (Quality Management), ISO 14001 (Environmental Management), ASME, CE, PED, and specific national boiler codes. This indicates a commitment to quality and safety.

- Years of Experience & Track Record: Longevity in the industry and a proven portfolio of successful installations speak volumes about a vendor's reliability and expertise.

- Technological Innovation: Assess the integration of modern features such as advanced PLC control, remote monitoring capabilities, high-efficiency burners, and exhaust gas heat recovery systems.

- Customization Capabilities: For specific process requirements, the ability to provide `oem boiler thermal oil` solutions—tailored capacity, fuel options, footprint, control integration, and auxiliary equipment—is paramount.

- After-Sales Support & Service Network: Availability of technical support, spare parts, maintenance contracts, and local service teams ensures minimal downtime and sustained performance.

- Warranty and Guarantees: Comprehensive warranty terms and clear performance guarantees reflect the manufacturer's confidence in their product.

Comparison Table: General Thermal Oil Boiler Features

| Feature | Vendor A (Premium) | Vendor B (Standard) | Vendor C (Budget) |

|---|---|---|---|

| Thermal Efficiency (Gas) | ≥ 92% (with economizer) | ≥ 90% | ≥ 88% |

| Control System | Advanced PLC + HMI + Remote | Standard PLC + HMI | Basic Digital Controller |

| Burner Type | Low NOx, fully modulating | Modulating | Two-stage |

| Certifications | ASME, CE, PED, ISO 9001 | CE, ISO 9001 | Local Certs, ISO 9001 |

| Warranty (Major Components) | 2-3 Years | 1-2 Years | 1 Year |

| After-Sales Support | Global, 24/7 Remote, On-site | Regional, Business Hours | Limited, Local |

Working with an experienced `oem boiler thermal oil` provider ensures that the heating system is not merely a standalone unit but an integral, optimized component of the entire production process. This often involves close collaboration during the design phase, factory acceptance testing, and commissioning to guarantee seamless integration and performance.

Real-World Application Case Studies & Tailored Solutions

The practical deployment of Horizontal/Vertical type YQW/L gas or diesel oil fired thermal oil boiler heaters demonstrates their tangible benefits in diverse industrial settings. These case studies highlight how customized solutions lead to improved efficiency, cost savings, and enhanced operational reliability.

Case Study 1: Petrochemical Plant - Enhanced Reactor Heating

A leading petrochemical facility required a robust and precise heating solution for its polymerization reactors, demanding stable temperatures up to 300°C. Their existing steam system struggled with temperature fluctuations and high maintenance due to scaling. We supplied a custom 5,000 kW (4.3 Mcal/h) horizontal thermal oil boiler system, integrated with a closed-loop primary and secondary heat exchanger network.

- Solution: A gas-fired YQW series thermal oil boiler with a PLC-based control system for precise temperature modulation.

- Outcome: The plant reported a 12% reduction in energy consumption due to higher thermal efficiency and elimination of steam losses. Reactor temperature stability improved from ±5°C to ±1°C, leading to more consistent product quality and reduced batch rejection rates. Maintenance costs associated with water treatment and blowdown were completely eliminated.

Case Study 2: Textile Dyeing and Finishing Mill - Optimized Drying Processes

A large textile mill in Asia faced challenges with inconsistent heat delivery to their stenter and drying machines, affecting fabric finish and increasing cycle times. They needed a high-temperature, clean heating medium. A vertical YQL series thermal oil boiler of 3,000 kW (2.5 Mcal/h) was recommended for its compact footprint and high efficiency.

- Solution: A diesel oil-fired vertical thermal oil boiler, chosen for fuel flexibility, with an integrated flue gas economizer.

- Outcome: The mill achieved a 15% improvement in drying speed and a 7% reduction in fuel costs. The stable, uniform heat provided by the boiler thermal oil system eliminated temperature gradients in the drying chambers, resulting in more consistent fabric quality and color fastness. Downtime related to boiler issues reduced by 25%.

Customized Solutions for Specific Needs:

Every industrial process has unique requirements, and bespoke `oem boiler thermal oil` solutions are often necessary to achieve optimal performance. Customization options include:

- Fuel Flexibility: Designing boilers to run on multiple fuels (e.g., natural gas, LPG, diesel, heavy oil, or even bio-oil) to adapt to local availability and cost fluctuations.

- Footprint Optimization: Vertical configurations for sites with limited space, or horizontal designs for specific installation layouts.

- Advanced Control Systems: Integration with plant-wide DCS (Distributed Control Systems), remote monitoring, and diagnostic capabilities for smart factories.

- Auxiliary Equipment: Customization of expansion tanks, deaerators, heat exchangers, circulating pumps, and filtration systems to form a complete, harmonized `thermal oil system`.

- Special Materials: Use of specific alloys or coatings for extreme operating conditions or corrosive environments.

Figure 3: An Installed Horizontal Thermal Oil Boiler System.

Ensuring Trustworthiness: FAQ, Lead Time, Warranty & Support

Building trust with B2B clients involves not only delivering high-performance products but also providing transparency in operational aspects and robust after-sales support. This section addresses common inquiries and outlines our commitment to customer satisfaction for our Horizontal/Vertical type YQW/L gas or diesel oil fired thermal oil boiler heater.

Frequently Asked Questions (FAQ):

- Q: What is the typical lifespan of a thermal oil boiler?

- A: With proper maintenance and use of quality thermal fluid, our boilers are designed for a service life of 20-25 years, often exceeding this in optimal conditions.

- Q: How often does thermal oil need to be replaced?

- A: Thermal oil degradation depends on operating temperature and exposure to oxygen. Regular oil analysis (typically annually) is recommended. Quality thermal oil, operated within its limits, can last 5-10 years or more before significant top-up or replacement is needed.

- Q: What kind of maintenance does a thermal oil system require?

- A: Maintenance is generally simpler than steam boilers. It primarily involves annual thermal oil analysis, burner tuning, checking safety interlocks, inspecting insulation, and ensuring circulating pump health. No water treatment or blowdown is required.

- Q: Can your boilers operate on different fuel types?

- A: Yes, our YQW/L series boilers are designed for flexibility and can be supplied with burners capable of firing natural gas, LPG, diesel oil, light oil, or heavy oil. Dual-fuel options are also available.

- Q: Is installation complex?

- A: Our boilers are typically delivered as skid-mounted or modular units to simplify installation. We provide detailed installation manuals and can offer on-site supervision or full installation services if required.

Lead Time & Fulfillment:

Standard models of the Horizontal/Vertical type YQW/L series thermal oil boiler typically have a lead time of 8-12 weeks from order confirmation to ex-factory shipment. This period accounts for raw material procurement, manufacturing, rigorous testing, and final quality checks. Customized or large-capacity projects may require longer lead times, usually 12-16 weeks, depending on the complexity of specifications and material availability. We maintain transparent communication throughout the production cycle, providing regular updates to our clients.

Warranty Commitments:

We stand behind the quality and reliability of our products. All pressure parts of our boiler thermal oil units are covered by a 24-month warranty from the date of shipment or 18 months from commissioning, whichever comes first. Auxiliary components and electrical parts typically carry a 12-month warranty. Specific warranty terms will be detailed in the sales contract, ensuring clear commitments and peace of mind for our clients.

Comprehensive Customer Support:

Our commitment extends beyond delivery. We offer a multi-tiered customer support system:

- Technical Assistance: Our team of experienced engineers provides remote technical support via phone and email, available during business hours, and emergency support for critical issues.

- Spare Parts Supply: We maintain a comprehensive inventory of genuine spare parts to ensure prompt availability and minimize downtime.

- On-site Services: For complex installations, commissioning, troubleshooting, or major maintenance, our field service engineers are available for on-site support globally.

- Training Programs: We offer operational and maintenance training for your plant personnel, either at our facility or on-site, to ensure safe and efficient operation of the thermal oil boiler.

Authoritative References

- International Boiler & Pressure Vessel Code (ASME BPVC), Section I: Rules for Construction of Power Boilers. The American Society of Mechanical Engineers.

- European Directive 2014/68/EU on Pressure Equipment (PED). Official Journal of the European Union.

- ISO 9001:2015 Quality management systems — Requirements. International Organization for Standardization.

- Ullmann's Encyclopedia of Industrial Chemistry, Heat Transfer Media. Wiley-VCH Verlag GmbH & Co. KGaA.

- Chemical Engineering Handbook, Perry's. McGraw-Hill Professional.

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025