Thermal Oil Boiler: High Efficiency, Low Pressure, OEM—Why?

What I’m Seeing in Thermal Oil Heating: Field Notes, Specs, and Real-World Picks

If you’re weighing a thermal oil boiler for your plant, you’re probably balancing heat stability, safety, and fuel costs. Same here. In the last year, I’ve walked through textiles, asphalt and chemical sites that migrated away from steam to thermal oil and—honestly—the operational calm is noticeable. No constant blowdown. Fewer scale headaches. And yes, better control at 200–320°C.

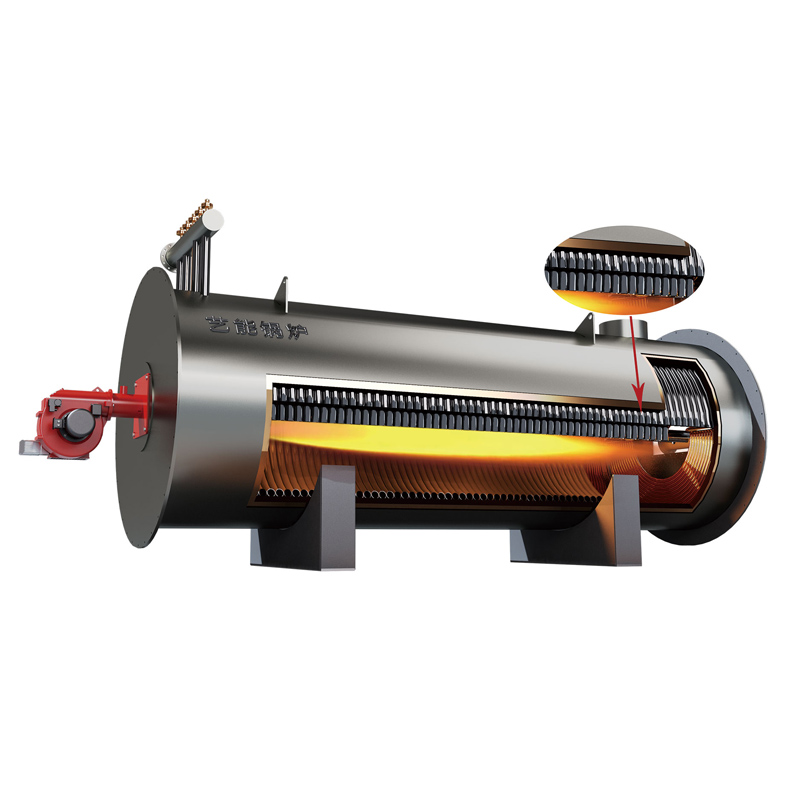

Product snapshot: YQW/L gas or diesel fired heater

Origin: Wuqiao, Hebei, China. The wet-back, internal-combustion, two-return design with a top coil tube prevents direct flame radiation on the rear wall—more radiant surface, better reliability. Many customers say the coil stays cleaner and ramp-up is smoother than earlier shell designs. To be frank, that top coil detail is the unsung hero here.

Industry trend check

- Low-NOx burners and O2 trim are now standard asks; thermal oil boiler buyers want sub-80 mg/m³ NOx in gas mode.

- Digitalization: PLC/SCADA with data logging, and predictive alarms on pump ΔP and oil degradation.

- Fuel flexibility: toggling between natural gas and diesel as a hedge—still common, especially in APAC.

How it’s built (process flow, tests, lifespan)

Materials: coil in seamless boiler tube (≈20# / ASTM A106 Gr.B), shell in Q235B; fully welded, stress-relieved. Methods: CNC coil-winding, submerged arc welding, flange machining, refractory-lined furnace, then insulation and aluminum jacket. Testing: 100% visual + dimensional checks; NDT per NB/T 47013 (UT/RT on pressure welds); hydrostatic test at ≈1.5× design; burner compliance EN 676 (gas) / EN 267 (oil). Real-world service life: 8–15 years with proper fluid management (ASTM D6743 checks help). Many maintenance teams, frankly, underestimate oil sampling; don’t.

Typical specs

| Model | YQW (Horizontal) / YQL (Vertical) |

| Heat capacity | ≈0.2–7 MW (real-world sizing may vary) |

| Outlet oil temperature | Up to ≈320°C at low system pressure |

| Thermal efficiency | ≈90–95% with proper tuning/insulation |

| Fuel | Natural gas / LPG / Diesel oil |

| Emissions (gas) | NOx ≈30–80 mg/m³ with low-NOx burner |

| Controls | PLC + HMI; O2 trim; flame safeguard; interlocks |

| Certifications | ISO 9001; built per GB/T 17410; CE-compliant burners |

Where it excels

Textiles/dyeing, chemical reactors, wood-based panels (presses), printing/lamination, asphalt/bitumen terminals, food/process heating. Advantages of a thermal oil boiler: high temp at low pressure, stable film temps (less hot-spot coking), quick start/stop, no water-side scaling.

Vendor comparison (my short list)

| Vendor | Strengths | Considerations |

|---|---|---|

| YN Boilers (Wuqiao) | Wet-back two-return coil; solid efficiency; flexible gas/diesel; pragmatic pricing | Lead time varies by burner brand; specify insulation thickness early |

| International A | Global service network; advanced analytics packages | Higher CAPEX; longer shipping for APAC sites |

| Regional B (OEM) | Fast delivery; local spare parts | Spec variability; verify testing documentation |

Customization notes

- Burners: Riello/Weishaupt/Baltur; dual-fuel if you like options.

- Controls: Siemens/Schneider PLC; remote monitoring add-on.

- Skid-mounted circulation pump set; air preheater for fuel savings.

- Oil management: side-stream filters, expansion tank sizing per GB/T guidance—critical for any thermal oil boiler.

Case snapshots

Coating plant, Vietnam — 2.4 MW YQW. Gas-fired, O2 trim. Plant reports ≈12% gas reduction vs. legacy unit; NOx ≈45 mg/m³; uptime 98.7% over 12 months.

Bitumen terminal, MEA — 3.0 MW YQL vertical feeding tank coils. Operators note stable 180–200°C with minimal coking; maintenance window extended to annual.

What to verify before PO

- Performance test protocol per GB/T 17410 and emissions target tied to burner spec.

- NDT dossiers, hydro test records, and material traceability (MTCs).

- Thermal oil choice and ASTM/DIN tests; plan quarterly sampling, honestly.

Authoritative references

- GB/T 17410 — Organic Heat Carrier (Thermal Oil) Boilers Standard. http://openstd.samr.gov.cn

- NB/T 47013 — Nondestructive Testing of Pressure Equipment. http://www.sac.gov.cn

- EN 676 & EN 267 — Automatic forced draught burners. https://standards.cen.eu

- ASTM D6743 — Thermal Stability of Organic Heat Transfer Fluids. https://www.astm.org/d6743

- EU MCPD (2015/2193) — Medium Combustion Plant Emissions. https://eur-lex.europa.eu

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025