Thermal Oil Boiler | High Efficiency & Precise Control

If you’ve ever walked through a textiles plant or a plywood mill, you can almost feel the heat doing quiet, consistent work. That’s where a good thermal oil boiler earns its living—steady temperature, minimal fuss, long hours.

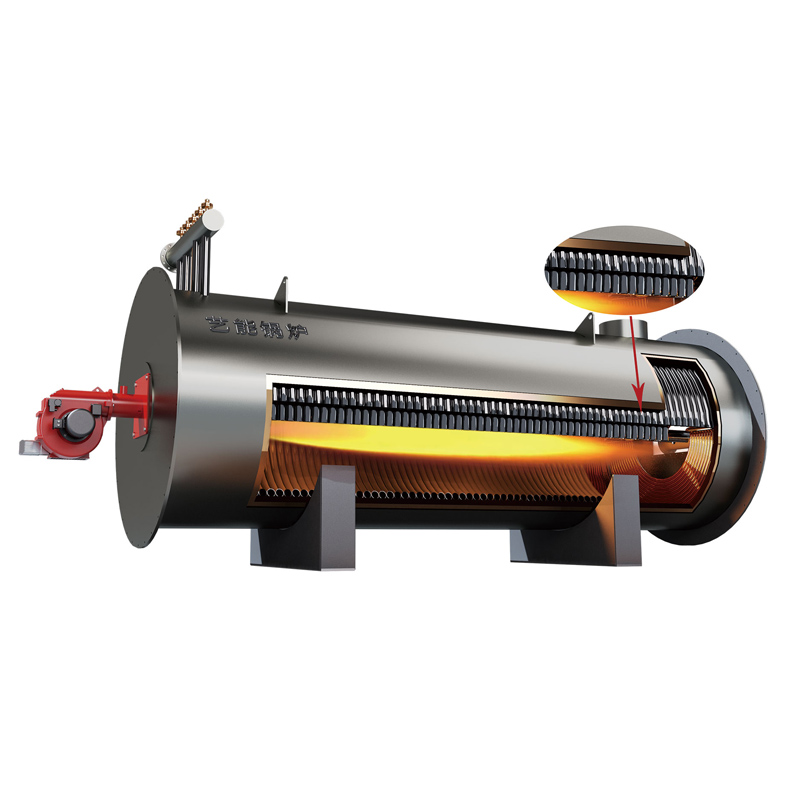

The Horizontal/Vertical type YQW/L gas or diesel oil fired heater (origin: Wuqiao, Hebei, China) is—speaking frankly—a workhorse. It uses a wet-back internal combustion two-pass layout with a top coil tube, which shields the rear wall from flame radiation and bumps up the radiation area. In practice, that design nudges real-world efficiency higher than you’d expect for its class. Many customers say startup is quick and temperature control feels “boringly reliable,” which, in process heating, is high praise.

Industry trends, briefly

Three themes keep coming up: lower NOx burners, smarter PLC control, and safer heat-transfer fluids. Plants are pushing to 300–330°C setpoints without steam complexity, and a modern thermal oil boiler makes that feasible—no deaerator, fewer blowdown headaches, fewer corrosion issues.

Specs that matter

| Model | YQW (horizontal) / YQL (vertical) |

| Heat capacity | ≈ 0.35–7 MW (real-world sizing may vary) |

| Design temperature | Up to ~320°C (fluid-dependent) |

| Working pressure | Typically ≤ 1.1 MPa (thermal fluid circuit) |

| Thermal efficiency | 90–95% with economizer |

| Fuel | Natural gas / LPG / diesel |

| Structure | Wet-back, two-pass; top coil tube for rear-wall protection |

| Coil/materials | Seamless coils (e.g., GB/T 3087 or ASTM A106 Gr.B) |

| Emissions (NOx) | ≈ 30–80 mg/Nm³ with low-NOx burner |

| Controls | PLC with multi-point temperature/flow interlocks |

| Origin | Wuqiao, Hebei, China |

Where it fits (and why)

- Chemicals, resins, bitumen/asphalt, printing & dyeing

- Wood-based panels, laminates, MDF presses

- Food and edible oils (with approved fluids), plastics extrusion

Advantages? Stable high temperature at low pressure, less corrosion, and quick payback where process temperature drift used to ruin product quality. Honestly, once a plant shifts to a thermal oil boiler, they rarely go back to steam for these duties.

Manufacturing and QA, in short

Materials: pressure-grade boiler steel (e.g., Q345R), seamless coils; Methods: automated coil winding, TIG/MAG welding, stress-relief heat treatment; Testing: hydrostatic at ≈1.5× design pressure, pneumatic leak checks, NDT (RT/UT) on critical seams, burner tuning and full-load trial. Compliance typically aligns with DIN 4754 for thermal-oil systems and NFPA 87 for fluid heaters; many buyers ask for ISO 9001 and CE marks. Service life: around 15–20 years with regular fluid analysis and strainer maintenance.

Vendor snapshot (real-world buying notes)

| Vendor | Efficiency | NOx | Certs | Warranty | Lead time |

|---|---|---|---|---|---|

| YQW/L (this model) | ≈ 92–95% (with economizer) | ≈ 30–80 mg/Nm³ | ISO 9001, CE (buyer confirm) | 12–18 months typical | 4–8 weeks (config-dependent) |

| Vendor A (generic import) | ≈ 88–92% | ≈ 80–120 mg/Nm³ | ISO 9001 | 12 months | 6–10 weeks |

| Vendor B (regional brand) | ≈ 90–94% | ≈ 50–100 mg/Nm³ | CE, local PED | 12–24 months | 8–12 weeks |

Customization and real feedback

- Burners: staged/fully premixed low-NOx

- Controls: PLC/SCADA, Modbus, redundant pumps

- Heat recovery: economizer + air preheater

Customers mention smoother temperature ramps and fewer product rejects after swapping to a thermal oil boiler. One plant manager told me, “we stopped babysitting the heat.” I get that.

Case snapshot

Laminate press line, 3.5 MW YQW unit at 310–320°C. After commissioning and a heat-balance test, fuel use dropped ≈11%, NOx tested at ~45 mg/Nm³, and thermal fluid stayed stable over six months of lab checks. Payback: about 14 months. Not bad.

Standards and references

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025