Thermal Oil Boiler Solutions for Efficient EPS Production and Cost Savings

Understanding Thermal Oil Boilers for EPS Production

The production of Expanded Polystyrene (EPS) has gained immense popularity in various industries due to its excellent insulation properties and lightweight nature. One of the critical components in the production process of EPS is the thermal oil boiler. In this article, we will explore the significance of thermal oil boilers in the EPS manufacturing process, their operational mechanisms, and why they are an essential investment for companies engaged in EPS production.

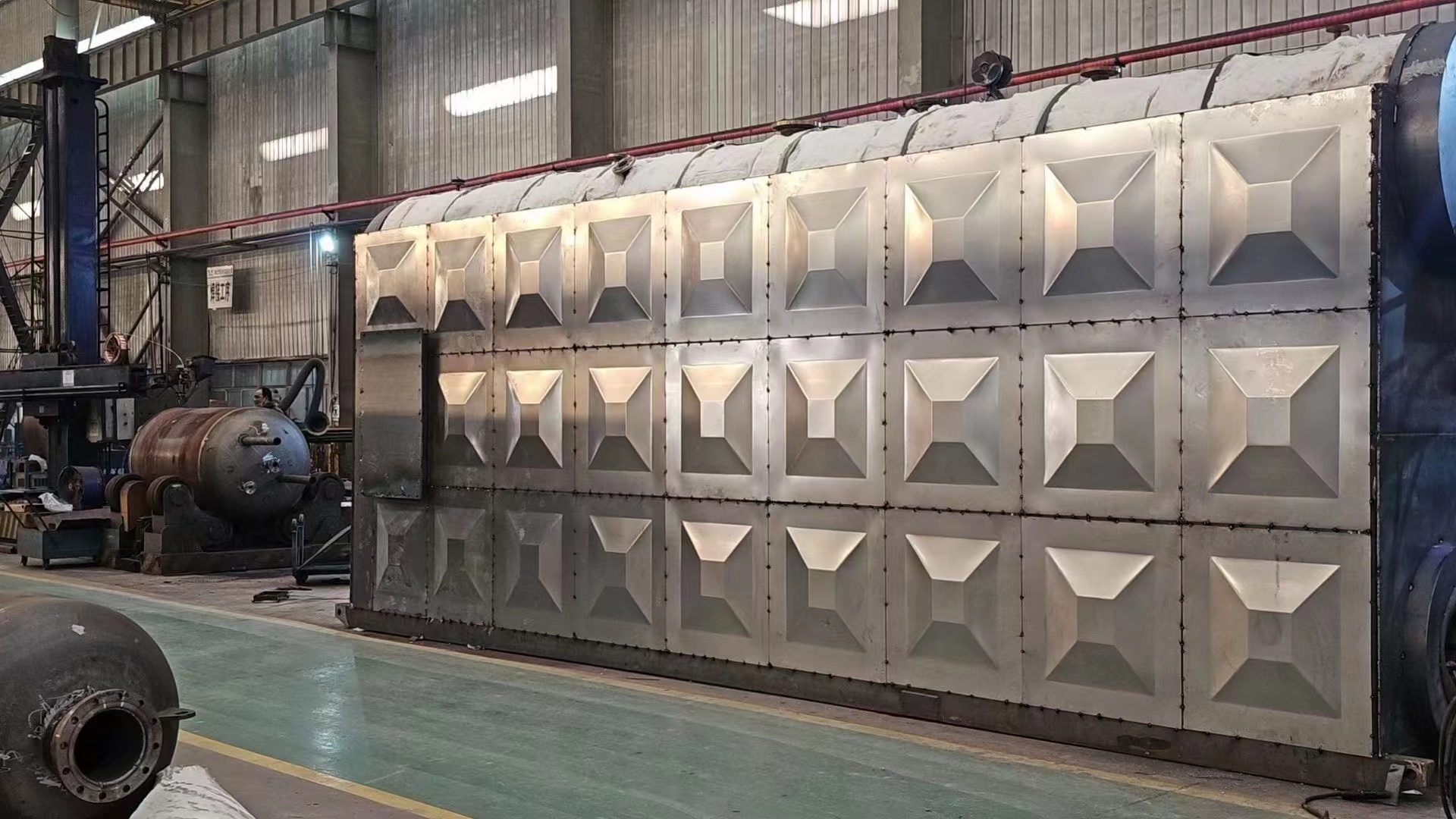

What is a Thermal Oil Boiler?

A thermal oil boiler is a specific type of boiler designed to heat oil to high temperatures, which can then be used to transfer heat efficiently. Unlike conventional steam boilers that operate by heating water to generate steam, thermal oil boilers use synthetic heat transfer fluids that can remain stable and effective at much higher temperatures, often exceeding 300 degrees Celsius. This property makes them ideal for industrial processes requiring consistent and precise temperature control.

The Role of Thermal Oil Boilers in EPS Production

In the EPS manufacturing process, the thermal oil boiler plays a pivotal role in providing the necessary heat for various applications, including the pre-expansion of polystyrene beads and the molding process. EPS production generally involves the following steps

1. Pre-Expansion Raw polystyrene beads are expanded using steam. The thermal oil boiler supplies the steam, enabling the beads to swell and form a lightweight material that is crucial for achieving the desired insulation characteristics.

2. Molding Post-expansion, the beads are molded into required shapes and sizes. Here, precise temperature control is vital as it determines the properties of the final EPS product. Thermal oil systems can provide uniform heating that ensures mold quality and reduces production times.

3. Chilling Once molded, the EPS products often require cooling. Thermal oil systems can also be utilized in the chilling process by circulating cooled oil to remove excess heat from the molded products, allowing for quicker handling and packaging.

Benefits of Using Thermal Oil Boilers

1. Efficiency Thermal oil boilers are designed to maintain high thermal efficiency while consuming less energy. This efficiency translates into lower operational costs for EPS manufacturers.

thermal oil boiler for eps quotes

3. Uniform Heating Thermal oil heating systems provide consistent heat distribution, enhancing product quality in EPS production and minimizing defects.

4. Reduced Maintenance With fewer components and lower pressure systems, thermal oil boilers typically require less maintenance compared to traditional high-pressure steam boilers, leading to reduced downtime.

5. Environmental Considerations Modern thermal oil boilers are designed with sustainability in mind. Many models are equipped with advanced technology to minimize emissions and ensure compliance with environmental regulations.

Choosing the Right Thermal Oil Boiler

When selecting a thermal oil boiler for EPS production, several factors should be considered

1. Capacity The capacity of the boiler must match the production requirements of the EPS facility to ensure operational efficiency.

2. Temperature Range It is essential to select a boiler capable of achieving the required temperature for specific EPS manufacturing processes.

3. Fuel Type Depending on local regulations and availability, businesses can opt for different fuel types, including natural gas, diesel, or renewable energy sources.

4. Automation and Control Systems Advanced control systems allow for precise monitoring and management of the thermal oil system, optimizing performance and improving safety.

5. Supplier Reputation Choosing a reputable supplier with extensive experience in thermal oil boiler manufacture and support can greatly enhance operational reliability.

Conclusion

In summary, thermal oil boilers are a vital component in the production of Expanded Polystyrene (EPS), ensuring efficient heat transfer and management throughout the manufacturing process. As industries continue to prioritize energy efficiency and product quality, investing in a high-quality thermal oil boiler becomes crucial for EPS manufacturers. By understanding the role of these boilers and making informed choices, businesses can enhance their production processes and maintain a competitive edge in the market.

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025

-

High-Efficiency Thermal Oil Boiler for Industrial Heating SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers for Industrial EfficiencyNewsJul.28,2025