Jan . 20, 2025 01:27

Back to list

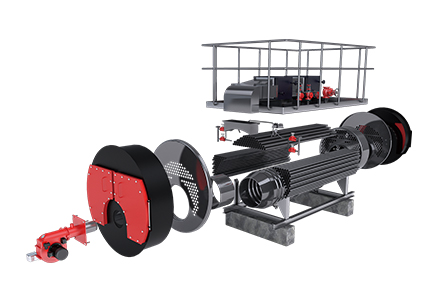

thermal oil boiler for woodworking industry

Thermal oil boilers have become indispensable in the woodworking industry, serving as a catalyst that enhances efficiency, safety, and productivity. With the unique demands this sector imposes on temperature management and energy costs, selecting an ideal thermal oil boiler isn't just a choice—it's a strategic decision that can fuel growth and ensure sustainability.

Trustworthiness is our foundational value. Our thermal oil boilers undergo rigorous quality control checks and industry-standard testing before they reach the customer. We offer comprehensive warranties and after-sales support, ensuring that our clients receive not just a product but a long-term service commitment. Moreover, our customer service team comprises engineers and industry experts ready to assist in maintenance, troubleshooting, and optimizing boiler usage to extend its lifespan and efficiency. From experience in the field, real-world applications have demonstrated how our thermal oil boilers improve operational throughput by up to 20%. This increase is attributed to reduced downtime and enhanced equipment reliability, underscoring the return on investment for woodworking enterprises leveraging our technology. In the modern industrial scenario where energy costs are unpredictable, incorporating a thermal oil boiler tailored for the woodworking industry acts as a safeguard against fluctuating expenses. By operating on various fuel types including gas, diesel, or biomass, businesses can choose the most cost-effective and sustainable fuel option available. In conclusion, choosing a thermal oil boiler for the woodworking industry is about investing in efficiency, safety, and long-term productivity. Equipped with the right partner, woodworking businesses can achieve unprecedented growth and sustainable operations through technology that delivers unmatched precision and reliability.

Trustworthiness is our foundational value. Our thermal oil boilers undergo rigorous quality control checks and industry-standard testing before they reach the customer. We offer comprehensive warranties and after-sales support, ensuring that our clients receive not just a product but a long-term service commitment. Moreover, our customer service team comprises engineers and industry experts ready to assist in maintenance, troubleshooting, and optimizing boiler usage to extend its lifespan and efficiency. From experience in the field, real-world applications have demonstrated how our thermal oil boilers improve operational throughput by up to 20%. This increase is attributed to reduced downtime and enhanced equipment reliability, underscoring the return on investment for woodworking enterprises leveraging our technology. In the modern industrial scenario where energy costs are unpredictable, incorporating a thermal oil boiler tailored for the woodworking industry acts as a safeguard against fluctuating expenses. By operating on various fuel types including gas, diesel, or biomass, businesses can choose the most cost-effective and sustainable fuel option available. In conclusion, choosing a thermal oil boiler for the woodworking industry is about investing in efficiency, safety, and long-term productivity. Equipped with the right partner, woodworking businesses can achieve unprecedented growth and sustainable operations through technology that delivers unmatched precision and reliability.

Latest news

-

Top Industrial Boiler Contractors Supplier & Factory Quality Products & ServicesNewsJun.10,2025

-

Panasonic Hot Water Boiler - Reliable & Energy Efficient Heating SolutionNewsJun.10,2025

-

Pennco Steam Boilers High-Efficiency & Durable SolutionsNewsJun.10,2025

-

Industrial Boiler & Mechanical Solutions Efficient Industrial Heating SystemsNewsJun.10,2025

-

Panasonic Hot Water Boiler - Energy-Efficient, Reliable Heat SolutionNewsJun.10,2025

-

Premium Power Plant Steam Boilers High Efficiency & ReliabilityNewsJun.09,2025